Abstract

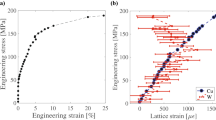

The origin of the extraordinary strengthening of the highly alloyed austenitic stainless steel Sanicro 25 during cyclic loading at 700 °C was investigated by the use of advanced scanning transmission electron microscopy (STEM). Along with substantial change of the dislocation structure, nucleation of two distinct populations of nanoparticles was revealed. Fully coherent Cu-rich nanoparticles were observed to be homogeneously dispersed with high number density along with nanometer-sized incoherent NbC carbides precipitating on dislocations during cyclic loading. Probe-corrected high-angle annular dark-field STEM imaging was used to characterize the atomic structure of nanoparticles. Compositional analysis was conducted using both electron energy loss spectroscopy and high spatial resolution energy dispersive X-ray spectroscopy. High-temperature exposure-induced precipitation of spatially dense coherent Cu-rich nanoparticles and strain-induced nucleation of incoherent NbC nanoparticles leads to retardation of dislocation movement. The pinning effects and associated obstacles to the dislocation motion prevent recovery and formation of the localized low-energy cellular structures. As a consequence, the alloy exhibits remarkable cyclic hardening at elevated temperatures.

Similar content being viewed by others

References

H. Mughrabi: Dislocations in Fatigue, in Dislocations and Properties of Real Materials (The Institute of Metals, London, 1985); p. 244.

H. Mughrabi and H-J. Christ: Cyclic deformation and fatigue of selected ferritic and austenitic steels: Specific aspects. ISIJ Int. 37, 1154 (1997).

C. Laird, P. Charsley, and H. Mughrabi: Low energy dislocation structures produced by cyclic deformation. Mater. Sci. Eng., A 81, 433 (1986).

H. Mughrabi: Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals. Acta Metall. 31, 1367 (1983).

P. Marshall: Austenitic Stainless Steels—Microstructure and Mechanical Properties, 1st ed. (Springer, London, England, 1984); p. 432.

P.J. Maziasz and J.T. Busby: Properties of austenitic steels for nuclear reactor applications. In Comprehensive Nuclear Materials, Vol. 2, R.J.M. Konings, ed. (Elsevier, Amsterdam, the Netherlands, 2012); p. 267.

G. Chai and U. Forsberg: Sanicro 25: An advanced high-strength, heat-resistant austenitic stainless steel. In Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants, A. Di Gianfrancesco, ed. (Elsevier, Amsterdam, the Netherlands, 2017); p. 391.

J. Polák, R. Petráš, M. Heczko, I. Kuběna, T. Kruml, and G. Chai: Low cycle fatigue behavior of Sanicro 25 steel at room and at elevated temperature. Mater. Sci. Eng., A 615, 175 (2014).

J. Polák, R. Petráš, M. Heczko, T. Kruml, and G. Chai: Evolution of the cyclic plastic response of Sanicro 25 steel cycled at ambient and elevated temperatures. Int. J. Fatigue 83, 75 (2016).

J. Polák, V. Mazánová, I. Kuběna, M. Heczko, and J. Man: Surface relief and internal structure in fatigued stainless Sanicro 25 steel. Metall. Mater. Trans. A 47, 1907 (2016).

J. Polák, V. Mazánová, M. Heczko, I. Kuběna, and J. Man: Profiles of persistent slip markings and internal structure of underlying persistent slip bands. Fatigue Fract. Eng. Mater. Struct. 40, 1101 (2017).

G. Chai, M. Boström, M. Olaison, and U. Forsberg: Creep and LCF behaviors of newly developed advanced heat resistant austenitic stainless steel for A-USC. Procedia Eng. 55, 232 (2013).

J. Zurek, S-M. Yang, D-Y. Lin, T. Huttel, L. Singheiser, and W.J. Quadakkers: Microstructural stability and oxidation behavior of Sanicro 25 during long-term steam exposure in the temperature range 600–750 °C. Mater. Corros. 66, 315 (2015).

M. Heczko, J. Polák, and T. Kruml: Microstructure and dislocation arrangements in Sanicro 25 steel fatigued at ambient and elevated temperatures. Mater. Sci. Eng., A 680, 168 (2017).

R. Petráš, V. Škorík, and J. Polák: Thermomechanical fatigue and damage mechanisms in Sanicro 25 steel. Mater. Sci. Eng., A 650, 52 (2016).

T. Sourmail: Precipitation in creep resistant austenitic stainless steels. Mater. Sci. Technol. 17, 1 (2001).

H.K. Danielsen, J. Hald, F.B. Grumsen, and M.A.J. Somers: On the crystal structure of Z-phase Cr(V,Nb)N. Metall. Mater. Trans. A 37, 2633 (2006).

K. Obrtlík, T. Kruml, and J. Polák: Dislocation structures in 316L stainless steel cycled with plastic strain amplitudes over a wide interval. Mater. Sci. Eng., A 187, 1 (1994).

S.I. Hong and C. Laird: Mechanisms of slip mode modification in F.C.C. solid solutions. Acta Metall. Mater. 38, 1581 (1990).

J. Lu, L. Hultman, E. Holström, K.H. Antonsson, M. Grehk, W. Li, L. Vitos, and A. Golpayegani: Stacking fault energies in austenitic stainless steels. Acta Mater. 111, 39 (2016).

D. Caillard and J-L. Martin: Thermally Activated Mechanisms in Crystal Plasticity, 1st ed., Pergamon Materials Series (Elsevier Science, Amsterdam, the Netherlands, 2003); p. 452.

M. Gerland, R. Alain, B. Ait Saadi, and J. Mendez: Low cycle fatigue behaviour in vacuum of a 316L-type austenitic stainless steel between 20 and 600 °C—Part II: Dislocation structure evolution and correlation with cyclic behaviour. Mater. Sci. Eng., A 229, 68 (1997).

M.S. Pham, C. Solenthaler, K.G.F. Janssens, and S.R. Holdsworth: Dislocation structure evolution and its effects on cyclic deformation response of AISI 316L stainless steel. Mater. Sci. Eng., A 528, 3261 (2011).

A.L. Bowman, G.P. Arnold, E.K. Storms, and N.G. Nereson: The crystal structure of Cr23C6. Acta Crystallogr., Sect. B: Struct. Crystallogr. Cryst. Chem. 28, 3102 (1972).

A. Tohyama and Y. Minami: Development of the high temperature materials for ultra super critical boilers. In Advanced Heat Resistant Steel for Power Generation, R. Viswanathan and J. Nutting, eds. (The Institute of Materials, London, U.K., 1999); p. 494.

J. Jiang and L. Zhu: Strengthening mechanisms of precipitates in S30432 heat-resistant steel during short-term aging. Mater. Sci. Eng., A 539, 170 (2012).

C. Chi, H. Yu, J. Dong, W. Liu, S. Cheng, Z. Liu, and X. Xie: The precipitation strengthening behavior of Cu-rich phase in Nb contained advanced Fe–Cr–Ni type austenitic heat resistant steel for USC power plant application. Prog. Nat. Sci.: Mater. Int. 22, 175 (2012).

D. Poddar, P. Cizek, H. Beladi, and P.D. Hodgson: Evolution of strain-induced precipitates in a model austenitic Fe–30Ni–Nb steel and their effect on the flow behavior. Acta Mater. 80, 1 (2014).

D.B. Williams and C.B. Carter: Transmission Electron Microscopy—A Textbook for Materials Science, 2nd ed. (Springer, USA, 2009); p. 775.

M.C. Carroll and L.J. Carroll: Fatigue and creep-fatigue deformation of an ultra-fine precipitate strengthened advanced austenitic alloy. Mater. Sci. Eng., A 556, 864 (2012).

G. Thomas: Kikuchi electron diffraction and applications. In Modern Diffraction and Imaging Techniques in Material Science, S. Amelinckx, R. Gevers, G. Remant, and L. Van Landuyt, eds. (North-Holland Publishing Co., Amsterdam, Holland, 1970); p. 746.

J.W. Edington: Electron Diffraction in the Electron Microscope (MacMillan Press, London, England, 1975); p. 136.

D.M. Haddrill, R.N. Youngerand, and R.G. Baker: Precipitation of niobium carbide on dislocations in austenite. Acta Metall. 9, 982 (1961).

Z. Zhang, Z. Hu, H. Tu, S. Schmauder, and G. Wu: Microstructure evolution in HR3C austenitic steel during long-term creep at 650 °C. Mater. Sci. Eng., A 681, 74 (2017).

C. Solenthaler, M. Ramesh, P.J. Uggowitzer, and R. Spolenak: Precipitation strengthening of Nb-stabilized TP347 austenitic steel by a dispersion of secondary Nb(C,N) formed upon a short-term hardening heat treatment. Mater. Sci. Eng., A 647, 294 (2015).

M.S. Pham and S.R. Holdsworth: Dynamic strain ageing of AISI 316L during cyclic loading at 300 °C: Mechanism, evolution, and its effects. Mater. Sci. Eng., A 556, 122 (2012).

J. Rösler and E. Arzt: A new model-based equation for dispersion strengthened materials. Acta Metall. Mater. 38, 671 (1990).

W. Kesternich: Dislocation-controlled precipitation of TiC particles and their resistance to coarsening. Philos. Mag. A 52, 533 (1985).

K.D. Challenger and J. Moteff: Characterization of the deformation substructure of AISI 316 stainless steel after high strain fatigue at elevated temperatures. Metall. Trans. 3, 1675 (1972).

J. Bressers and M. Steen: Fatigue and microstructure in austenitic high temperature alloys. Int. J. Pressure Vessels Piping 47, 217 (1991).

ACKNOWLEDGMENTS

The present work was conducted in the frame of IPMinfra supported through the project No. LM2015069 and the project CEITEC 2020 No. LQ1601 of MEYS. The support by the project RVO: 68081723 and grant 13-23652S of the Grant Agency of the Czech Republic is gratefully acknowledged. MJM acknowledges the support of the National Science Foundation under contract #DMR-60050072. BDE acknowledges support from the Center for Emergent Materials: an NSF MRSEC under award number DMR-1420451. The support of the Fulbright Fellowship grant awarded to Milan Heczko by The J. William Fulbright Commission in the Czech Republic is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Heczko, M., Esser, B.D., Smith, T.M. et al. On the origin of extraordinary cyclic strengthening of the austenitic stainless steel Sanicro 25 during fatigue at 700 °C. Journal of Materials Research 32, 4342–4353 (2017). https://doi.org/10.1557/jmr.2017.311

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.311