Abstract

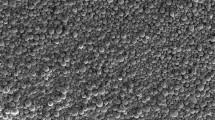

In a hot forming process, the study of the interface tool/product proves important. This study focuses on the influence of the third body in the case of pin-on-disc in an open contact. The objective of this work was to identify the third body-particle circulation mechanisms at high temperatures. The “wear and friction” tests were conducted with an open sliding contact on pairs of X40CrMoV5/Fe360B steels under a normal force of 70 N at 600 °C and with a speed of rotation of the disc of 50 rev/min. The pin material was X40CrMoV5 (AISI H13) steel and the disc material was Fe360B steel. Scanning electronic microscope, energy-dispersive spectroscopy (EDS), and X-ray diffractometer explored the development surface damage and oxides tribo-oxides. It was concluded that various types of the third body particles were present in the contact. The wear mechanism on the X40CrMoV5 pin in a high temperature contact is proposed.

Similar content being viewed by others

References

K. Dohda, C. Boher, F. Rezai-Aria, and N. Mahayotsanun: Tribology in metal forming at elevated temperatures. Friction 3, 1–27 (2015).

C. Richard: Tribocorrosion at elevated temperatures in the metal working industry. In Tribocorrosion of Passive Metals and Coatings, D. Landolt and S. Mischler eds. (Woodhead Press, Cambridge, 2011); pp. 517–536.

S.C. Ho, J.H. Chern Lin, and C.P. Ju: Effect of fiber addition on mechanical and tribological properties of a copper/phenolic-based friction material. Wear 258, 861–869 (2005).

P.P. Yao, H.C. Sheng, X. Xiong, and B.Y. Huang: Worn surface characteristics of Cu-based powder metallurgy bake materials for aircraft. Trans. Nonferrous Met. Soc. China 17, 99–103 (2007).

A. Kovlchenko, O. Fushchichi, and S. Danyluk: The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper. Wear 290, 106–123 (2012).

Y.L. Xiao, P.P. Yao, H.B. Zhou, Z.Y. Zhang, T.M. Gong, L. Zhao, X.T. Zuo, M.W. Deng, and Z.X. Jin: Friction and wear behavior of copper matrix composite for spacecraft rendezvous and docking under different conditions. Wear 320, 127–134 (2014).

M. Godet: The third-body approach: A mechanical view of wear. Wear 100, 431–452 (1984).

S. Decarthes and Y. Berthier: Rheology and flows of solid third bodies: Background and application to an MoS1.6 coating. Wear 252, 546–556 (2002).

W. Österle, I. Dorfel, C. Prietzel, H. Rooch, A-L. Cristol-Bulthé, G. Degallaix, and Y. Deplanques: A comprehensive microscopic study of third body formation at the interface between a brake pad and brake disc during the final stage of a pin-on-disc test. Wear 267, 781–788 (2009).

A. Marcellan, O. Bondil, C. Boué, and A. Chateuminois: Third body effects in the wear of polyamide: Micro-mechanisms and wear particles analysis. Wear 266, 1013–1020 (2009).

E. Niccollini and Y. Berthier: Wheel-rail adhesion: Laboratory study of “natural” third body role on locomotives wheels and rails. Wear 258, 1172–1178 (2005).

W. Östrelle, A.I. Dmitriev, and H. Kloß: Possible impacts of third body nanostructure on friction performance during dry sliding determined by computer simulation based on the method of movable cellular automata. Tribol. Int. 48, 128–136 (2005).

A. Descarthes, C. Desrayaudb, E. Niccolonic, and Y. Berthier: Presence and role of the third body in a wheel-rail contact. Wear 258, 1081–1090 (2005).

W. Östrelle and I. Urban: Third body formation on brake pads and rotors. Tribol. Int. 39, 401–408 (2006).

Q. Zhu, H.T. Zhu, A.K. Tieu, and C. Kong: Three dimensional microstructure study of oxide scale formed on a high-speed steel by means of SEM, FIB and TEM. Corros. Sci. 53, 3603–3611 (2011).

F.H. Stott and G.C. Wood: The influence of oxides on the friction and wear of alloys. Tribol. Int. 201 (1978).

C. Vergne, C. Boher, C. Levaillant, and R. Gras: Analysis of the friction and wear behaviour of hot work tool scale: Application to the hot rolling process. Wear 250, 322–333 (2001).

A. Matuszak: Factors influencing friction in steel sheet forming. J. Mater. Process. Technol. 106, 250–253 (2000).

A. Fontalvo and C. Mitterer: The effects of oxide forming alloying elements on the high temperature wear of a hot work steel. Wear 258, 1491–1499 (2005).

C. Vergne, C. Boher, C. Levaillant, and R. Gras: 38th Workshop of the study circle of metal, Liège, Belgium, 1999.

O. Joos, C. Boher, and C. Vergne: Assessment of oxide scales influences on wear damage of HSM work rolls. Wear 263, 198–206 (2007).

E.D. Szakaly and J.G. Lenard: The effect of process and material parameters on the coefficient of friction in the flat-die test. J. Mater. Process. Technol. 210, 868–876 (2010).

P. Lepesant, C. Boher, Y. Berthier, and F. Rezai-Aria: A phenomenological model of the third body particles circulation in a high temperature contact. Wear 299, 66–79 (2013).

H.S. Hong and W.O. Winner: The role of atmospheres and lubricants in the oxidational wear of metals. Tribol. Int. 35, 725–729 (2002).

F.H. Stott, J. Gascott, and G.C. Wood: Models of generations of oxides during sliding wear. Proc. R. Soc. London, Ser. A 402, 167–186 (1985).

J. Jiang, F.H. Stott, and M.M. Stack: A mathematical model for sliding wear of metals at elevated temperatures. Wear 181, 20–31 (1995).

Z. Baccouch, R. Mnif, R. Elleuch, and C. Richard: Analysis of friction, wear and oxidation behaviour of X40CrMoV5/Fe360B steel couple in an open-sliding contact. J. Eng. Tribol. 228, 276–287 (2014).

ACKNOWLEDGMENTS

The authors acknowledge SOPAL Society (Tunisia), especially its head manager for his precious help and contribution to this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baccouch, Z., Mnif, R., Elleuch, R. et al. Contribution to modeling the wear mechanism of X40CrMoV5/Fe360B steel couple in an open sliding contact at high temperature. Journal of Materials Research 32, 2601–2608 (2017). https://doi.org/10.1557/jmr.2017.28

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.28