Abstract

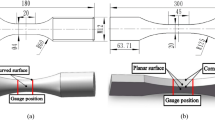

The high-cycle fatigue (HCF) behavior is significantly affected by surface roughness, especially for high strength metal FV520B-I. However, with surface roughness effect, neither the fatigue property, nor the high-cycle fatigue life model about FV520B-I with surface roughness has been reported. In this paper, designed fatigue experiment using the specimen with different surface roughness is presented to study the effectiveness of the roughness to the fatigue. The observations of the fatigue crack initiation sites and the crack propagation. Then the high cycle fatigue behavior of FV520B-I affected by surface roughness is analyzed. The existing very-high-cycle fatigue life model is not well-fit for high-cycle fatigue model of FV520B-I. A NEW high-cycle fatigue life prediction model of FV520B-I, taking surface roughness as a main effective variable is proposed. The model is built up by a comprehensive use of experimental data and the traditional fatigue modeling theory. The new finding between the fatigue strength coefficient and stress amplitude, with surface roughness, is adopted, leading to a NEW modified life prediction model. Study on fatigue model of FV520B-I with surface roughness is a very beneficial effort in fatigue theory and fatigue engineering development.

Similar content being viewed by others

References

A. Farzad, A. Mohamadreza, and A. Jamshid: Effects of surface quality and loading history on fatigue life of laser-machined poly(methyl methacrylate). Mater. Des. 65, 473–481 (2015).

M. Zhang, W.Q. Wang, P.F. Wang, Y. Liu, and J.F. Li: The fatigue behavior and mechanism of FV520B-I with large surface roughness in a very high cycle regime. Eng. Failure Anal. 66, 432–444 (2016).

J.L. Wang, Y.L. Zhang, S.J. Liu, Q.C. Sun, and H.T. Lu: Competitive giga-fatigue life analysis owing to surface defect and internal inclusion for FV520B-I. Int. J. Fatigue 87, 203–209 (2016).

J.L. Wang, Y.L. Zhang, Q.C. Sun, S.J. Liu, B.W. Shi, and H.T. Lu: Giga-fatigue life prediction of FV520B-I with surface roughness. Mater. Des. 89, 1024–1038 (2016).

M. Zhang, W.Q. Wang, P.F. Wang, Y. Liu, and J.F. Li: Fatigue behavior and mechanism of FV520B-I in ultrahigh cycle regime. Procedia Mater. Sci. 3, 2035–2041 (2014).

J.M. Mao, W.C. Liu, Y.L. Li, G.L. Wei, L. Zhang, W.B. Zou, Y. Tian, and G.H. Wu: Influence of different casting processes on high cycle fatigue behavior of Mg–10Gd–3Y–0.5Zr alloy. J. Mater. Res. 31, 2538–2548 (2016).

Y.N. Song, Z.G. Xing, H.D. Wang, P.F. He, and B.S. Xu: Very high cycle bending fatigue behaviors of FV520B steel under fretting wear. J. Mater. Res. 31, 1748–1754 (2016).

D. Jin, J.H. Li, and N. Shao: The effect of dynamic strain aging on fatigue property for 316L stainless steel. J. Mater. Res. 31, 627–634 (2016).

Y.T. Lv, M. Hu, L.Q. Wang, X.Y. Xu, Y.F. Han, and W.J. Lu: Influences of heat treatment on fatigue crack growth behavior of NiAl bronze (NAB) alloy. J. Mater. Res. 30, 3041–3048 (2015).

L.K. Jiang, W.C. Liu, Y.L. Li, G.H. Wu, and W.J. Ding: High cycle fatigue behavior of different regions in a low-pressure sand-cast GW103K magnesium alloy component. J. Mater. Res. 29, 2587–2595 (2014).

Y. Murakami, S. Kodama, and S. Konuma: Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. I: Basic fatigue mechanism and evaluation of correlation between the fatigue fracture stress and the size and location of non-metallic inclusions. Int. J. Fatigue 11, 291–298 (1989).

Y. Murakami and M. Endo: Quantitative evaluation of fatigue strength of metals containing various small defects of cracks. Eng. Fract. Mech. 17, 1–15 (1983).

Y. Murakami: Metal Fatigue-effects of Small Defects and Nonmetallic Inclusions, Vol. 6–7 (Elsevier, Amsterdam, 2002); pp. 314–316.

Z. Sun and Y.K. Qian: Failure analysis for the early fatigue fracture of major axle of slurry pump. Heat Treat. Met. 5, 32–34 (2000).

S.K. As, B. Kallerud, B.W. Tveten, and B. Holme: Fatigue life prediction of machined components using finite element analysis of surface topography. Int. J. Fatigue 27, 1590–1596 (2005).

S. Andrews and H. Sehitoglu: Acomputer model for fatigue crack growth form rough surface. Int. J. Fatigue 22, 619–630 (2000).

H. Wang and Q. Gao: Effect of load frequency on fatigue behavior of material in ultrasonic fatigue testing. Part: A Phys. Test 41, 433–435 (2005).

ACKNOWLEDGMENT

The authors gratefully acknowledge the financial support from the National Key Base Research and Development Program (No. 2011CB013401) and the National Natural Science Foundations of China (51375074, 51475077).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Jl., Zhang, Yl., Zhao, Qc. et al. The fatigue failure analysis and fatigue life prediction model of FV520B-I as a function of surface roughness in HCF regime. Journal of Materials Research 32, 634–643 (2017). https://doi.org/10.1557/jmr.2016.513

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.513