Abstract

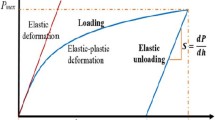

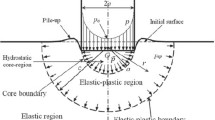

Nanoindentation techniques are commonly used to characterize nanomechanical properties of microscaled and nanoscaled materials. Nanoindentation using a cylindrical flat-tip indenter has a constant contact area which makes it a reliable source to find material’s yield strength as well as other mechanical properties. However, an angular misalignment of the indenter with the specimen results in experimental error. In this work, the effects of angular misalignment on the nanoindentation testing with a cylindrical flat-tip indenter were numerically analyzed. A three-dimensional nanoindentation solid model was generated, computer modeling based on finite element analysis was conducted. The angle of misalignment ranged from 0° to 1°. Young’s modulus and hardness were evaluated. Based on the hemispherical stress–strain distribution assumption of an elastic plastic indentation, corrected depths and modifiers were proposed for adjusting material’s 0.1% offset and 0.2% offset yield strengths. Low carbon steel AISI 1018 was selected as sample material for indentation testing and modeling validation.

Similar content being viewed by others

References

International Organization for Standardization: ISO/DIS 14577-1 Metallic Materials-Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method (2002).

American Society for Testing and Materials: ASTM E2546-07 Standard Practice for Instrumented Indentation Testing, ASTM International (2007).

A.C. Fischer-Cripps: Nanoindentation. In Mechanical Engineering Series, 3rd ed., Springer: New York, NY, USA (2011).

Z. Hu, M. Shrestha, and Q.H. Fan: Nanomechanical characterization of porous anodic aluminum oxide films by nanoindentation. Thin Solid Films 598, 131 (2016).

Z. Hu, K.J. Lynne, S.P. Markondapatnaikuni, and F. Delfanian: Material elastic–plastic property characterization by nanoindentation testing coupled with computer modeling. Mater. Sci. Eng., A 587, 268 (2013).

Z. Hu, K. Lynne, and F. Delfanian: Characterization of materials’ elasticity and yield strength through micro-/nano-indentation testing with a cylindrical flat-tip indenter. J. Mater. Res. 30(4), 578 (2015).

S.C. Wright, Y. Huang, and N.A. Fleck: Deep penetration of polycarbonate by a cylindrical punch. Mech. Mater. 13, 277 (1992).

L. Cheng, X. Xia, W. Yu, L.E. Scriven, and W.W. Gerberich: Flat-punch indentation of viscoelastic material. J. Polym. Sci., Part B: Polym. Phys. 38, 10 (2000).

J.I. Eldridge, D. Zhu, and R.A. Miller: Mesoscopic nonlinear elastic modulus of thermal barrier coatings determined by cylindrical punch indentation. J. Am. Ceram. Soc. 84(11), 2737 (2001).

B.X. Xu, B. Zhao, and Z.F. Yue: Finite element analysis of the indentation stress characteristics of the thin film/substrate systems by flat cylindrical indenters. Materialwiss. Werkstofftech. 37(8), 681 (2006).

Z. Chunyu: Characterization of the mechanical properties of visco-elastic and visco-elastic-plastic materials by nanoindentation tests. PhD. Thesis, National University of Singapore, Singapore, 2007.

A. Gisario, M. Barletta, and A. Boschetto: Characterization of laser treated steels using instrumented indentation by cylindrical flat punch. Surf. Coat. Technol. 202, 2557 (2008).

Y.C. Lu and D.M. Shinozaki: Characterization and modeling of large displacement micro/nano-indentation of polymeric solids. J. Eng. Mater. Technol. 130(4), 041001 (2008).

Y.C. Lu, S.N.V.R.K. Kurapati, and F. Yang: Finite element analysis of cylindrical indentation for determining plastic properties of materials in small volumes. J. Phys. D: Appl. Phys. 41, 115415 (2008).

E.B. Tadmor, R. Miller, and R. Phillips: Nanoindentation and incipient plasticity. J. Mater. Res. 14(6), 2233 (1999).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19(1), 3 (2004).

A. Srivastava: Dynamic friction measurement and modeling at the micro/nano scale. Ph.D. thesis, University of california, USA, 2006.

Z. Xu and X. Li: Effect of sample tilt on nanoindentation behavior of materials. Philos. Mag. 87(16), 2299 (2007).

C.G.N. Pelletier, E.C.A. Dekkers, L.E. Govaert, J.M.J. den Toonder, and H.E.H. Meijer: The influence of indenter-surface misalignment on the results of instrumented indentation tests. Polym. Test. 26, 949 (2007).

M.S. Kashani: Sources of error in relating nanoindentation results to material properties. Ph.D. thesis, Wichita State University, USA, 2010.

C. Shi, H. Zhao, H. Huang, L. Xu, L. Ren, M. Bai, J. Li, and X. Hu: Effects of indenter tilt on nanoindentation results of fused silica: An investigation by finite element analysis. Mater. Trans. 54(6), 958 (2013).

Z. Wang, A.A. Volinsky, and N.D. Gallant: Nanoindentation study of polydimethylsiloxane elastic modulus using Berkovich and flat punch tips. J. Appl. Polym. Sci. 132(5), 41384 (2015).

F.D. Paoli and A.A. Volinsky: Obtaining full contact for measuring polydimethylsiloxane mechanical properties with flat punch nanoindentation. MathodsX 2, 374 (2015).

ANSYS Inc.: ANSYS Theory Reference Manual. ANSYS version 15.0, 2015.

W.E. Baker, P.S. Westine, and F.T. Dodge: Similarity methods in engineering Dynamics: Theory and practice of scale modeling, revised edition. In Fundamental Studies in Engineering, 12; Elsevier Science Publishers B.V., Amsterdam, The Netherlands, 1991; pp. 97–118.

B. Zohuri: Dimensional Analysis and Self-similarity Methods for Engineers and Scientists (Springer International Publishing, Switzerland, 2015); pp. 93–193.

J.R. Davis: Metals Handbook, 2nd ed. (ASM International, Materials Park, 1998); pp. 153–173.

ACKNOWLEDGMENTS

The authors gratefully acknowledge generous support from the South Dakota Research Infrastructure Center Programs of Composite and Nanocomposite Advanced Manufacturing Center (CNAM) and the Materials Evaluation and Testing Lab (METLab), along with the Department of Mechanical Engineering at South Dakota State University. Help from Kevin Lynne for contacting nanoindentation tests and computational facility supported from University High Performance Computing at South Dakota State University are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahjahan, N.B., Hu, Z. Effects of angular misalignment on material property characterization by nanoindentation with a cylindrical flat-tip indenter. Journal of Materials Research 32, 1456–1465 (2017). https://doi.org/10.1557/jmr.2016.478

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.478