Abstract

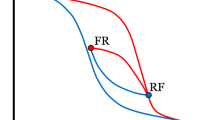

A theoretical model for the Functionally Graded Shape Memory Alloy (FG-SMA) cylinders subjected to internal pressure is investigated. The gradient properties in this work are embodied in the Young’s modulus and Poisson’s ratio gradient through the thickness of the cylinder. The critical transformation stresses and maximum formation strain are all assumed to be constant. Combining the elasticity and exponential function of the Young’s modulus and Poisson’s ratio with the different gradient parameters, the elastic stress distributions and displacement distributions for the FG-SMA cylinder under the internal pressure are obtained, respectively. To get the theoretical solution, the Tresca yield function and the ideal elastic–plastic constitutive model are selected for the shape memory alloy to illustrate the phase transformation. The relationships between the internal pressure and total strain at the internal radius with different gradient parameters are then given, and the results show that the total strains are greatly influenced by the different parameters.

Similar content being viewed by others

References

M. Koizumi: The concept of FGM. Ceram. Trans. 39, 3–10 (1993).

B. Skoczen: Functionally graded structural members obtained via the low temperature strain induced phase transformation. Int. J. Solids Struct. 44, 5182–5207 (2007).

P. Sittner, L. Heller, J. Pilch, C. Curfs, T. Alonso, and D. Favier: Young’s modulus of austenite and martensite phases in superelastic NiTi wires. J. Mater. Eng. Perform. 23(7), 2303–2314 (2014).

S.U. Rehman, M. Khan, A.N. Khan, L. Ali, and S.H.I. Jaffery: Two-step martensitic transformation in an aged Ti50Ni15Pd25Cu10 high temperature shape memory alloys. Acta Phys. Pol., A 128(2B), B125–B127 (2015).

X-B. Wang, J.V. Humbeeck, B. Verlinden, and S. Kustov: Thermal cycling induced room temperature aging effect in Ni-rich NiTi shape memory alloy. Scr. Mater. 113, 206–208 (2016).

C. Haberland, M. Elahinia, J.M. Walker, H. Meier, and J. Frenzel: On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 23(10), 64–75 (2014).

H-B. Lu, C-R. Lu, W-M. Huang, and J-S. Leng: Chemo-responsive shape memory effect in shape memory polyurethane triggered by inductive release of mechanical energy storage undergoing copper(II) chloride migration. Smart Mater. Struct. 24(3), 035018 (2015).

H-B. Lu, J-S. Leng, and S-Y. Du: A phenomenological approach for the chemo-responsive shape memory effect in amorphous polymers. Soft Matter 9(14), 3851–3858 (2013).

M. Samadpour, M. Sadighi, M. Shakeri, and H.A. Zamani: Vibration analysis of thermally buckled SMA hybrid composite sandwich plate. Compos. Struct. 119, 251–263 (2015).

H. Asadi, Y. Kiani, M. Shakeri, and M.R. Eslami: Exact solution for nonlinear thermal stability of hybrid laminated composite Timoshenko beams reinforced with SMA fibers. Compos. Struct. 108, 811–822 (2014).

D.C. Lagoudas: Shape Memory Alloys: Modeling and Engineering Applications (Springer, New York, 2008).

Z.W. Zhong and C.K. Yeong: Development of a gripper using SMA wire. Sens. Actuators, A 126(2), 375–381 (2006).

S. Guo, J. Oohira, and T. Fukuda: A novel type of micropump using SMA actuator for microflow application. Presented at the IEEE Int. Conference Robot. Autom. Vol. 987–992, 2003.

J-H. Qiu, Y-X. Bian, H-L. Ji, and K-J. Zhu: The application of intelligent material structure in the aviation field. Aviat Manuf. Tech. 3, 26–29 (2009). (in Chinese).

B.T. Lester, Y. Chenisky, and D.C. Lagoudas: Transformation characteristics of shape memory alloy composites. Smart Mater. Struct. 20, 094002 (2011).

Y-Q. Fu, H-J. Du, and S. Zhang: Functionally graded TiN/TiNi shape memory alloy films. Mater. Lett. 57, 2995–2999 (2003).

S. Belyaev, V. Rubanik, N. Resnina, V. Rinamol, Jr, O. Rubanik, and V. Borisov: Martensitic transformation and physical properties of ‘steel-TiNi’ bimetal composite, produced by explosion welding. Phase Transitions 83(4), 276–283 (2010).

H. Tian, D. Schryvers, K.P. Mohanchandra, G.P. Carman, and J.V. Humbeeck: Fabrication and characterization of functionally graded Ni–Ti multilayer thin films. Funct. Mater. Lett. 2(2), 61–66 (2009).

B. Zheng, J. Xu, and M. Qi: Preparation of graded DLC film on TiNi SMA by plasma enhanced deposition and behavior of corrosion-resistance. J. Funct. Mater. 38(1), 115–118 (2007).

B.F. Liu, G.S. Dui, and S.Y. Yang: On the transformation behavior of functionally graded SMA composites subjected to thermal loading. Eur. J. Mech. A-Solid. 40, 139–147 (2013).

A. Pequegnat, A. Michael, J. Wang, K. Lian, Y. Zhou, and M.I. Khan: Surface characterizations of laser modified biomedical grade NiTi shape memory alloys. Mater. Sci. Eng., C 50(3), 367–378 (2015).

S. Belyaev, V. Rubanik, N. Resnina, V. Rinamol, Jr, and I. Lomakin: Functional properties of ‘Ti50Ni50–Ti49.3Ni50.7’ shape memory composite produced by explosion welding. Smart Mater. Struct. 23, 085029 (2014).

J.H. Lim, M.S. Kim, J.P. Noh, Y.W. Kim, and T.H. Nam: Compositionally graded Ti–Ni alloys prepared by diffusion bonding. J. Nanosci. Nanotechnol. 14(12), 9042–9046 (2014).

R.M.S. Martins, N. Schell, H. Reuther, L. Pereira, K.K. Mahesh, R.J.C. Silva, and F.M.B. Fernandes: Texture development, microstructure and phase transformation characteristics of sputtered Ni–Ti shape memory alloy films grown on TiNi〈111〉. Thin Solid Films 519(1), 122–128 (2010).

Z. Yan, L-S. Cui, and Y-J. Zheng: Microstructure and martensitic transformation behaviors of explosively welded NiTi/NiTi laminates. Chin. J. Aeronaut. 20, 168–171 (2007).

Y-P. Zhang, X-P. Zhang, and Z-Y. Zhong: Fabrication, transformation and superelasticity behavior of NiTi memory alloy with large pore-size and gradient porosity. Acta Metall. Sin. 43(11), 1221–1227 (2007).

B.S. Shariat, Y-N. Liu, and G. Rio: Modelling and experimental investigation of geometrically graded NiTi shape memory alloys. Smart Mater. Struct. 22, 025030 (2013).

B.S. Shariat, Y-N. Liu, and G. Rio: Thermomechanical modelling of microstructurally graded shape memory alloys. J. Alloys Compd. 541, 407–414 (2012).

Q-L. Meng, Y-N. Liu, H. Yang, B.S. Shariat, and T.H. Nam: Functionally graded NiTi strips prepared by laser surface anneal. Acta Mater. 60(4), 1658–1668 (2012).

B.S. Shariat, Y-N. Liu, Q-L. Meng, and G. Rio: Analytical modelling of functionally graded NiTi shape memory alloy plates under tensile loading and recovery of deformation upon heating. Acta Mater. 61(9), 3411–3421 (2013).

M.F. Razali and A.S. Mahmud: Gradient deformation behavior of NiTi alloy by ageing treatment. J. Alloys Compd. 618, 182–186 (2015).

D. Hartl and D.C. Lagoudas: Aerospace applications of shape memory alloys. J. Aerospace Eng. 221(4), 535–552 (2007).

M.A. Qidwai, P.B. Entchrv, D.C. Lagoudas, and V.G. DeGiorgi: Modeling of the thermomechanical behavior of porous shape memory alloys. Int. J. Solids Struct. 38, 8653–8671 (2001).

A.S. Mahmud, Y-N. Liu, and T.H. Nam: Gradient anneal of functionally graded NiTi. Smart Mater. Struct. 17, 015031 (2008).

V. Birman: Stability of functionally graded shape memory alloy sandwich panels. Smart Mater. Struct. 6, 278–286 (1997).

J-C. Han, L. Xu, B-L. Wang, and X-H. Zhang: The research progress and prospects of functionally gradient materials. J. Solid Rocket Technol. 27(3), 207–215 (2004). (in Chinese).

H. Asadi, A.H. Akbarzadeh, Z-T. Chen, and M.M. Aghdam: Enhanced thermal stability of functionally graded sandwich cylindrical shells by shape memory alloys. Smart Mater. Struct. 24(4), 045022 (2015).

E. Bagherizadeh, Y. Kiani, and M.R. Eslami: Mechanical buckling of functionally graded material cylindrical shells surrounded by Pasternak elastic foundation. Compos. Struct. 93(11), 3063–3071 (2011).

R. Mirzaeifar, M. Shakeri, R. Desroches, and A. Yavari: A semi-analytic analysis of shape memory alloy thick-walled cylinders under internal pressure. Arch. Appl. Mech. 81(8), 1093–1116 (2011).

D.J. Miller, L.A. Fahnestock, and M.R. Eatherton: Development and experimental validation of a nickel–titanium shape memory alloy self-centering buckling-restrained brace. Eng. Struct. 40, 288–298 (2012).

J. Leng, X. Yan, X. Zhang, D. Huang, and Z. Gao: Design of a novel flexible shape memory alloy actuator with multilayer tubular structure for easy integration into a confined space. Smart Mater. Struct. 25(2), 025007 (2016).

F.B. Hildebrand: Introduction to Numerical Analysis (McGraw-Hill, New York, America, 1974).

B-F. Liu, G-S. Dui, and Y-P. Zhu: On phase transformation behavior of porous shape memory alloys. J. Mech. Behav. Biomed. Mater. 5(1), 9–15 (2012).

ACKNOWLEDGMENTS

The authors acknowledge the financial support of National Natural Science Foundation of China (Nos. 11502284; U1533103; 51505483; and 11272136) and it is also supported by the Fundamental Research Funds for the Central Universities (3122016C006) of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, B., Hu, S., Zhang, W. et al. A theoretical model for functionally graded shape memory alloy cylinders subjected to internal pressure. Journal of Materials Research 32, 1397–1406 (2017). https://doi.org/10.1557/jmr.2016.468

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.468