Abstract

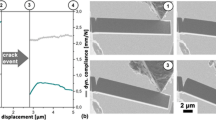

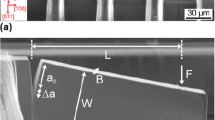

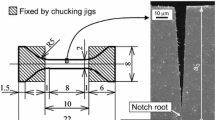

We designed a clamped beam bending test using a nanoindentation holder with help of transmission electron microscopy (TEM) and focused ion beam specimen fabrication. The microstructure evolution and crack propagation in nanocrystalline TiN were studied by electron imaging and load-displacement measurements during mechanical loading. By measuring the loads under which the crack starts and stops propagating and the time, we obtained the film’s fracture toughness using the finite element method and crack propagation speed. Among these, we identified three types of crack propagation pathways, namely bridging, intergranular and a mixed mode of transgranular and intergranular fracture, and the associated microstructure changes. The measured fracture toughness is in agreement with the reported values. Thus, our in situ TEM bending test provides the first direct measurement of fracture toughness in a TEM and a correlation of fracture toughness with fracture toughening mechanisms in nanocrystalline TiN. The method is general and can be applied to other nanocrystalline materials.

Similar content being viewed by others

References

M.A. Meyers, A. Mishra, and D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51(4), 427 (2006).

H. Gleiter: Nanocrystalline materials. Prog. Mater Sci. 33(4), 223 (1989).

K.S. Kumar, H. Van Swygenhoven, and S. Suresh: Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 51(19), 5743 (2003).

J. Schiotz, F.D. Di Tolla, and K.W. Jacobsen: Softening of nanocrystalline metals at very small grain sizes. Nature 391(6667), 561 (1998).

C. Suryanarayana: Nanocrystalline materials. Int. Mater. Rev. 40(2), 41 (1995).

M.W. Chen, E. Ma, K.J. Hemker, H.W. Sheng, Y.M. Wang, and X.M. Cheng: Deformation twinning in nanocrystalline aluminum. Science 300(5623), 1275 (2003).

J. Schiotz and K.W. Jacobsen: A maximum in the strength of nanocrystalline copper. Science 301(5638), 1357 (2003).

I.W. Chen and X.H. Wang: Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature 404(6774), 168 (2000).

M. Dao, L. Lu, R.J. Asaro, J.T.M. De Hosson, and E. Ma: Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 55(12), 4041 (2007).

S.C. Tjong and H. Chen: Nanocrystalline materials and coatings. Mater. Sci. Eng., R 45(1–2), 1 (2004).

E.M. Bringa, A. Caro, Y.M. Wang, M. Victoria, J.M. McNaney, B.A. Remington, R.F. Smith, B.R. Torralva, and H. Van Swygenhoven: Ultrahigh strength in nanocrystalline materials under shock loading. Science 309(5742), 1838 (2005).

L. Lu, M.L. Sui, and K. Lu: Superplastic extensibility of nanocrystalline copper at room temperature. Science 287(5457), 1463 (2000).

Y. Wang, M. Chen, F. Zhou, and E. Ma: High tensile ductility in a nanostructured metal. Nature 419(6910), 912 (2002).

Z. Shan, J.A. Knapp, D.M. Follstaedt, E.A. Stach, J.M.K. Wiezorek, and S.X. Mao: Inter- and intra-agglomerate fracture in nanocrystalline nickel. Phys. Rev. Lett. 100, 105502 (2008).

D. Farkas, H. Van Swygenhoven, and P.M. Derlet: Intergranular fracture in nanocrystalline metals. Phys. Rev. B 66, 060101 (2002).

A. Hasnaoui, H. Van Swygenhoven, and P.M. Derlet: Dimples on nanocrystalline fracture surfaces as evidence for shear plane formation. Science 300(5625), 1550 (2003).

I. Szlufarska, A. Nakano, and P. Vashishta: A crossover in the mechanical response of nanocrystalline ceramics. Science 309(5736), 911 (2005).

I.A. Ovid’ko and A.G. Sheinerman: Special strain hardening mechanism and nanocrack generation in nanocrystalline materials. Appl. Phys. Lett. 90, 171927 (2007).

I.A. Ovid’ko and A.G. Sheinerman: Nanocrack generation at dislocation-disclination configurations in nanocrystalline metals and ceramics. Phys. Rev. B 77, 054109 (2008).

I.A. Ovid’ko, A.G. Sheinerman, and E.C. Aifantis: Effect of cooperative grain boundary sliding and migration on crack growth in nanocrystalline solids. Acta Mater. 59(12), 5023 (2011).

I.A. Ovid’ko, A.G. Sheinerman, and E.C. Alfantis: Stress-driven migration of grain boundaries and fracture processes in nanocrystalline ceramics and metals. Acta Mater. 56(12), 2718 (2008).

V.A. Pozdnyakov and A.M. Glezer: Structural mechanisms of plastic deformation in nanocrystalline materials. Phys. Solid State 44(4), 732 (2002).

G. Wei, B. Bhushan, and S.J. Jacobs: Nanoscale fatigue and fracture toughness measurements of multilayered thin film structures for digital micromirror devices. J. Vac. Sci. Technol., A 22(4), 1397 (2004).

X.W. Gu, Z. Wu, Y-W. Zhang, D.J. Srolovitz, and J.R. Greer: Microstructure versus flaw: Mechanisms of failure and strength in nanostructures. Nano Lett. 13(11), 5703 (2013).

S. Kumar, X. Li, A. Haque, and H. Gao: Is stress concentration relevant for nanocrystalline metals?Nano Lett. 11(6), 2510 (2011).

J-H. Huang, Y-H. Chen, A-N. Wang, G-P. Yu, and H. Chen: Evaluation of fracture toughness of ZrN hard coatings by internal energy induced cracking method. Surf. Coat. Technol. 258, 211 (2014).

A-N. Wang, G-P. Yu, and J-H. Huang: Fracture toughness measurement on TiN hard coatings using internal energy induced cracking. Surf. Coat. Technol. 239, 20 (2014).

S. Zhang, D. Sun, Y.Q. Fu, and H.J. Du: Toughness measurement of thin films: A critical review. Surf. Coat. Technol. 198(1–3), 74 (2005).

B.N. Jaya, V. Jayaram, and S.K. Biswas: A new method for fracture toughness determination of graded (Pt,Ni)Al bond coats by microbeam bend tests. Philos. Mag. 92(25–27), 3326 (2012).

S. Liu, J.M. Wheeler, P.R. Howie, X.T. Zeng, J. Michler, and W.J. Clegg: Measuring the fracture resistance of hard coatings. Appl. Phys. Lett. 102, 171907 (2013).

K. Matoy, H. Schonherr, T. Detzel, T. Schoberl, R. Pippan, C. Motz, and G. Dehm: A comparative micro-cantilever study of the mechanical behavior of silicon based passivation films. Thin Solid Films 518(1), 247 (2009).

M.G. Mueller, V. Pejchal, G. Žagar, A. Singh, M. Cantoni, and A. Mortensen: Fracture toughness testing of nanocrystalline alumina and fused quartz using chevron-notched microbeams. Acta Mater. 86, 385 (2015).

S. Johansson, J.Å. Schweitz, L. Tenerz, and J. Tiren: Fracture testing of silicon microelements in situ in a scanning electron microscope. J. Appl. Phys. 63(10), 4799 (1988).

A.A. Yawny and J.E. Perez Ipina: In situ fracture toughness measurement using scanning electron microscopy. J. Test. Eval. 31(5), 413 (2003).

X. Zhang and S. Zhang: A Microbridge method in tensile testing of substrate for fracture toughness of thin films. Nanosci. Nanotechnol. Lett. 3(6), 735 (2011).

P. Chen and W-Y. Wu: The use of sputter deposited TiN thin film as a surface conducting layer on the counter electrode of flexible plastic dye-sensitized solar cells. Surf. Coat. Technol. 231, 140 (2013).

A-N. Wang, C-P. Chuang, G-P. Yu, and J-H. Huang: Determination of average x-ray strain (AXS) on TiN hard coatings using cos2αsin2ψ x-ray diffraction method. Surf. Coat. Technol. 262, 40 (2015).

C.H. Ma, J.H. Huang, and H. Chen: Nanohardness of nanocrystalline TiN thin films. Surf. Coat. Technol. 200(12–13), 3868 (2006).

S. Chan, I. Tuba, and W. Wilson: On the finite element method in linear fracture mechanics. Eng. Fract. Mech. 2(1), 1 (1970).

R.W. Hertzberg, R.P. Vinci, and J.L. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, 5th ed. (Wiley, New York, 2013).

S. Massl, W. Thomma, J. Keckes, and R. Pippan: Investigation of fracture properties of magnetron-sputtered TiN films by means of a FIB-based cantilever bending technique. Acta Mater. 57(6), 1768 (2009).

M.P. Manoharan, A.V. Desai, and M.A. Haque: Fracture toughness characterization of advanced coatings. J. Micromech. Microeng. 19(11), 115004 (2009).

S. Kataria, S.K. Srivastava, P. Kumar, G. Srinivas, J. Siju, J. Khan, D.V.S. Rao, and H.C. Barshilia: Nanocrystalline TiN coatings with improved toughness deposited by pulsing the nitrogen flow rate. Surf. Coat. Technol. 206(19–20), 4279 (2012).

B.N. Jaya and V. Jayaram: Crack stability in edge-notched clamped beam specimens: Modeling and experiments. Int. J Fract. 188(2), 213 (2014).

K.H. Kim, H. Xing, J.M. Zuo, P. Zhang, and H. Wang: TEM based high resolution and low-dose scanning electron nanodiffraction technique for nanostructure imaging and analysis. Micron 71, 39–45 (2015).

X.Z. Liao, F. Zhou, E.J. Lavernia, S.G. Srinivasan, M.I. Baskes, D.W. He, and Y.T. Zhu: Deformation mechanism in nanocrystalline Al: Partial dislocation slip. Appl. Phys. Lett. 83(4), 632 (2003).

H. Van Swygenhoven, P.M. Derlet, and A. Hasnaoui: Atomic mechanism for dislocation emission from nanosized grain boundaries. Phys. Rev. B 66(2), 024101 (2002).

H. Van Swygenhoven and J.R. Weertman: Deformation in nanocrystalline metals. Mater. Today 9(5), 24 (2006).

K.S. Kumar, S. Suresh, M.F. Chisholm, J.A. Horton, and P. Wang: Deformation of electrodeposited nanocrystalline nickel. Acta Mater. 51(2), 387 (2003).

ACKNOWLEDGMENTS

The work is supported by DOE BES (Grant No. DEFG02-01ER45923). Electron microscopy was carried out at the Center for Microanalysis of Materials at the Frederick Seitz Materials Research Laboratory of University of Illinois at Urbana–Champaign. The TiN specimen was prepared by Ms. An-Ni Wang with Department of Engineering and System Science, National Tsing Hua University at Hsinchu, Taiwan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Material

To view supplementary material for this article, please visit https://doi.org/10.1557/jmr.2016.4.

Supplementary Material

Rights and permissions

About this article

Cite this article

Hu, Y., Huang, JH. & Zuo, JM. In situ characterization of fracture toughness and dynamics of nanocrystalline titanium nitride films. Journal of Materials Research 31, 370–379 (2016). https://doi.org/10.1557/jmr.2016.4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.4