Abstract

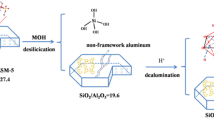

Zeolite–zeolite composite composed of alumina-rich hierarchically porous ZSM-5 cores and high-silicon MFI shells was prepared by a hydrothermal synthesis procedure, in which a commercial ZSM-5 zeolite with a SiO2/Al2O3 of 36 was treated by an alkaline solution and then used as a supporter for epitaxial growth of a polycrystalline Silicalite-1 zeolite shell (denoted as MMZsa). Acid sites associated with framework Al on exterior surfaces of ZSM-5 zeolite cores are therefore passivated in different degrees by the epitaxial MFI zeolite shell. The structural, crystalline, and textural properties of the as-synthesized samples were characterized by x-ray powder diffraction (XRD), energy-dispersive x-ray spectroscopy, X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), transmission electron microscopy (TEM), selected area electron diffraction (SAED), N2 adsorption-desorption, in situ IR spectra of pyridine and NH3-TPD. Aluminum species were observed to transfer from the alumina-rich cores to the high-silica shells. The adjustable thickness and SiO2/Al2O3 ratio of the shell offer the as-synthesized composite a potential and high-efficiency catalyst for methanol conversion into gasoline and diesel. As compared with the commercial ZSM-5 zeolite, the composite catalyst exhibits excellent catalytic performances with a longer catalytic life as well as a higher conversion and a slightly higher yield of diesel oil.

Similar content being viewed by others

References

A. Ghorbanpour, A. Gumidyala, L.C. Grabow, S.P. Crossley, and J.D. Rimer: Epitaxial growth of ZSM-5@silicalite-1: A core–shell zeolite designed with passivated surface acidity. ACS Nano 9, 4006 (2015).

Y. Isaev and J.J. Fripiat: A Lewis acid site-activated reaction in zeolites: Thiophene acylation by butyryl chloride. J. Catal. 182, 257 (1999).

G. Garralón, V. Fornés, and A. Corma: Faujasites dealuminated with ammonium hexafluorosilicate: Variables affecting the method of preparation. Zeolites 8, 268 (1988).

B.J. Shen, Z.X. Qin, X.H. Gao, F. Lin, S.G. Zhou, W. Shen, B.J. Wang, H.J. Zhao, and H.H. Liu: Desilication by alkaline treatment and increasing the silica to alumina ratio of zeolite Y. Chin. J. Catal. 33, 152 (2012).

Z.X. Qin, B.J. Shen, Z.W. Yu, F. Deng, L. Zhao, S. Zhou, D.L. Yuan, X.H. Gao, B.J. Wang, H.J. Zhao, and H.H. Liu: A defect-based strategy for the preparation of mesoporous zeolite Y for high-performance catalytic cracking. J. Catal. 298, 102 (2013).

M. Enterría, F. Suárez-García, A. Martínez-Alonso, and J.M.D. Tascón: Preparation of hierarchical micro-mesoporous aluminosilicate composites by simple Y zeolite/MCM-48 silica assembly. J. Alloys Compd. 583, 60 (2014).

L.X. Jia, X.Y. Sun, X.Q. Ye, C.L. Zou, H.F. Gu, Y. Huang, G.X. Niu, and D.Y. Zhao: Core–shell composite of USY@Mesosilica: Synthesis and application in cracking heavy molecules with high liquid yield. Microporous Mesoporous Mater. 176, 16 (2013).

S. Al-Khattaf: Catalytic transformation of toluene over a high-acidity Y-zeolite based catalyst. Energy Fuels 20, 946 (2006).

T. Odedairo and S. Al-Khattaf: Kinetic investigation of benzene ethylation with ethanol over USY zeolite in a riser simulator. Ind. Eng. Chem. Res. 49, 1642 (2010).

G. Agostini, C. Lamberti, L. Palin, M. Milanesio, N. Danilina, B. Xu, M. Janousch, and J.A. van Bokhoven: In situ XAS and XRPD parametric Rietveld refinement to understand dealumination of Y zeolite catalyst. J. Am. Chem. Soc. 132, 667 (2010).

D. Ma, F. Deng, R.Q. Fu, X.W. Han, and X.H. Bao: Mas NMR studies on the dealumination of zeolite MCM-22. J. Phys. Chem. B 105, 1770 (2001).

S.M. Maier, A. Jentys, and J.A. Lercher: Steaming of zeolite BEA and its effect on acidity: A comparative NMR and IR spectroscopic study. J. Phys. Chem. C 115, 8005 (2011).

L.R. Aramburo, L. Karwacki, P. Cubillas, S. Asahina, D.A. Matthijs de Winter, M.R. Drury, I.L.C. Buurmans, E. Stavitski, D. Mores, M. Daturi, P. Bazin, P. Dumas, F. Thibault-Starzyk, J.A. Post, M.W. Anderson, O. Terasaki, and B.M. Weckhuysen: The porosity, acidity, and reactivity of dealuminated zeolite ZSM-5 at the single particle level: The influence of the zeolite architecture. Chem.–Eur. J. 17, 13773 (2011).

Z. Qin, L. Lakiss, J-P. Gilson, K. Thomas, J-M. Goupil, C. Fernandez, and V. Valtchev: Chemical equilibrium controlled etching of MFI-type zeolite and its influence on zeolite structure, acidity, and catalytic activity. Chem. Mater. 25, 2759 (2013).

B.M. Chandra Shekara, B.S. Jai Prakash, and Y.S. Bhat: Dealumination of zeolite BEA under microwave irradiation. ACS Catal. 1, 193 (2011).

H.M. Kao and Y.C. Chen: 27Al and 19F solid-state NMR studies of zeolite H-β dealuminated with ammonium hexafluorosilicate. J. Phys. Chem. B 107, 3367 (2003).

C.S. Triantafillidis and N.P. Evmiridis: Dealuminated H-Y zeolites: Influence of the number and type of acid sites on the catalytic activity for isopropanol dehydration. Ind. Eng. Chem. Res. 39, 3233 (2000).

C.S. Triantafillidis, A.G. Vlessidis, and N.P. Evmiridis: Dealuminated H-Y zeolites: Influence of the degree and the type of dealumination method on the structural and acidic characteristics of H-Y zeolits. Ind. Eng. Chem. Res. 39, 307 (2000).

S. van Donk, A.H. Janssen, J.H. Bitter, and K.P. de Jong: Generation, characterization, and impact of mesopores in zeolite catalysts. Catal. Rev. 45, 297 (2003).

X.Y. Lin, Y. Fan, G. Shi, H.Y. Liu, and X.J. Bao: Coking, and deactivation behavior Of HZSM-5 zeolite-based FCC gasoline hydro-upgrading catalyst. Energy Fuels 21, 2517 (2007).

R.H. Abudawood, F.M. Alotaibi, and A.A. Garforth: Hydroisomerization of n-heptane over Pt-loaded USY zeolite. Effect of steaming, dealumination, and the resulting structure on catalytic properties. Ind. Eng. Chem. Res. 50, 9918 (2011).

T. Hibino, M. Niwa, and Y. Murakami: Shape-selectivity over HZSM-5 modified by chemical vapor deposition of silicon alkoxide. J. Catal. 128, 551 (1991).

J.H. Kim, A. Ishida, M. Okajima, and M. Niwa: Modification of HZSM-5 by CVD of various silicon compounds and generation of para-selectivity. J. Catal. 161, 387 (1996).

J. Cejka, N. Zilkova, B. Wichterlova, G. Elder-Mirth, and J.A. Lercher: Decisive role of transport rate of products for zeolite para-selectivity: Effect of coke deposition and external surface silylation on activity and selectivity of HZSM-5 in alkylation of toluene. Zeolites 17, 265 (1996).

S. Zheng, H. Tanaka, A. Jentys, and J.A. Lercher: Novel model explaining toluene diffusion in HZSM-5 after surface modification. J. Phys. Chem. B 108, 1337 (2004).

N.Y. Chen, W.W. Kaeding, and F.G. Dwyer: Para-directed aromatic reactions over shape-selective molecular sieve zeolite catalysts. J. Am. Chem. Soc. 101, 6783 (1979).

W.W. Kaeding, C. Chu, L.B. Young, B. Weinstein, and S.A. Butter: Selective alkylation of toluene with methanol to produce para-Xylene. J. Catal. 67, 159 (1981).

W.O. Parker, Jr. A. de Angelis, C. Flego, R. Millini, C. Perego, S. Zanardi: Unexpected destructive dealumination of zeolite beta by silylation. J. Phys. Chem. C 114, 8459 (2010).

C.R. Moreira, M.H. Herbst, P.R. de la Piscina, J-L.G. Fierro, N. Homs, and M.M. Pereira: Evidence of multi-component interaction in a V-Ce-HUSY catalyst: Is the cerium-EFAL interaction the key of vanadium trapping. Microporous Mesoporous Mater. 115, 253 (2008).

X.P. Duan, Y. Teng, A.J. Wang, V.M. Kogan, X. Li, and Y. Wang: Role of sulfur in hydrotreating catalysis over nickel phosphide. J. Catal. 261, 232 (2009).

K.K. Bando, Y. Koike, T. Kawai, G. Tateno, S.T. Oyama, Y. Inada, M. Nomura, and K. Asakura: Quick x-ray absorption fine structure studies on the activation process of Ni2P supported on K-USY. J. Phys. Chem. C 115, 7466 (2011).

W. Lutz, H. Toufar, D. Heidemann, N. Salman, C.H. Rüscher, and T.M. Gesing, J-Chr. Buhl, R. Bertram: Siliceous extra-framework species in dealuminated Y zeolites generated by steaming. Microporous Mesoporous Mater. 104, 171 (2007).

B. Féron, P. Gallezot, and M. Bourgogne: Hydrothermal aging of cracking catalysts: V. Vanadium passivation by rare-earth compounds soluble in the feedstock. J. Catal. 134, 469 (1992).

A.M. Goossens, B.H. Wouters, P.J. Grobet, V. Buschmann, L. Fiermans, and J.A. Martens: Synthesis and characterization of epitaxial FAU-on-EMT zeolite overgrowth materials. Eur. J. Inorg. Chem. 5, 1167 (2001).

A.L. Yonkeu, G. Miehe, H. Fuess, A.M. Goossens, and J.A. Martens: A new overgrowth of mazzite on faujasite zeolite crystal investigated by x-ray diffraction and electron microscopy. Microporous Mesoporous Mater. 96, 396 (2006).

M. Miyamoto, T. Kamei, N. Nishiyama, Y. Egashira, and K. Ueyama: Single crystals of ZSM-5/Silicalites composites. Adv. Mater. 17, 1985 (2005).

M. Okamoto and Y. Osafune: MFI-type zeolite with a core–shell structure with minimal defects synthesized by crystal overgrowth of aluminum-free MFI-type zeolite on aluminum-containing zeolite and its catalytic performance. Microporous Mesoporous Mater. 143, 413 (2011).

X.W. Zhang, Q. Guo, B. Qin, Z.Z. Zhang, F.X. Ling, W.F. Sun, and R.F. Li: Structural features of binary microporous zeolite composite Y-beta and its hydrocracking performance. Catal. Today 149, 212 (2010).

J.J. Zheng, X.W. Zhang, Y. Wang, Y.D. Bai, W.F. Sun, and R.F. Li: Synthesis and catalytic performance of a bi-phase core-shell zeolite composite. J. Porous Mater. 16, 731 (2009).

T. Ohsuna, O. Terasaki, Y. Nakagawa, S.I. Zones, and K. Hiraga: Electron microscopic study of intergrowth of MFI and MEL: Crystal faults in B-MEL. J. Phys. Chem. B 101, 9881 (1997).

K.R. Kloetstra, H.W. Zandbergen, J.C. Jansen, and H. van Bekkum: Overgrowth of mesoporous MCM-41 on faujasite. Microporous Mater. 6, 287 (1996).

X.F. Qian, J.M. Du, B. Li, M. Si, Y.S. Yang, Y.Y. Hu, G.X. Niu, Y.H. Zhang, H.L. Xu, B. Tu, Y. Tang, and D.Y. Zhao: Controllable fabrication of uniform core–shell structured zeolite@SBA-15 composites. Chem. Sci. 2, 2006 (2011).

L.D. Rollmann: ZSM-5 containing alumin-free shells on its surface. USA Patent, 4088605, May 9, 1978.

D.J. Kong, W. Zou, J.L. Zheng, X.L. Qi, and D.Y. Fang: Crystallization kinetics and influencing factors in the syntheses of MFI/MFI core–shell zeolites. Acta Chim. Sin. 25, 1921 (2009).

Y.X. Zhou, W.Y. Tong, W. Zou, X.L. Qi, and D.J. Kong: Manufacture of b-oriented ZSM-5/silicalite-1 core/shell structured zeolite catalyst. Synth. React. Inorg., Met.-Org., Nano-Met. Chem. 45, 1356 (2015).

C.S. Lee, T.J. Park, and W.Y. Lee: Alkylation of toluene over double structure ZSM-5 type catalysts covered with a silicalite shell. Appl. Catal., A 96, 151 (1993).

Q.H. Li, Z. Wang, J. Hedlund, D. Creaser, H. Zhang, X.D. Zou, and A-J. Bons: Synthesis and characterization of colloidal zoned MFI crystals. Microporous Mesoporous Mater. 78, 1 (2005).

D.V. Vu, M. Miyamoto, N. Nishiyama, S. Ichikawa, Y. Egashira, and K. Ueyama: Catalytic activities and structures of silicalite-1/H-ZSM-5 zeolite composites. Microporous Mesoporous Mater. 115, 106 (2008).

D.V. Vu, M. Miyamoto, N. Nishiyama, Y. Egashira, and K. Ueyama: Selective formation of para-xylene over H-ZSM-5 coated with polycrystalline silicalite crystals. J. Catal. 243, 389 (2006).

M. Ogura, S. Shinomiya, J. Tateno, Y. Nara, M. Nomura, E. Kikuchi, and M. Matsukata: Alkali-treatment technique—New method for modification of structural and acid-catalytic properties of ZSM-5 zeolites. Appl. Catal., A 219, 33 (2001).

Z.T. Xue, J.H. Ma, T. Zhang, H.X. Miao, and R.F. Li: Synthesis of nanosized ZSM-5 zeolite with intracrystalline mesopores. Mater. Lett. 68, 1 (2012).

R. Liu, Y. Ren, Y. Shi, F. Zhang, L. Zhang, B. Tu, and D. Zhao: Controlled synthesis of ordered mesoporous C-TiO2 nanocomposites with crystalline titania frameworks from organic-inorganic-amphiphilic coassembly. Chem. Mater. 20, 1140 (2008).

J.J. Zheng, Q.H. Zeng, Y.Y. Zhang, Y. Wang, J.H. Ma, X.W. Zhang, W.F. Sun, and R.F. Li: Hierarchical porous zeolite composite with a core–shell structure fabricated using β-zeolite crystals as nutrients as well as cores. Chem. Mater. 22, 6065 (2010).

Q.Q. Zhang, W.X. Ming, J.H. Ma, J.L. Zhang, P. Wang, and R.F. Li: De novo assembly of a mesoporous beta zeolite with intracrystalline channels and its catalytic performance for biodiesel production. J. Mater. Chem. A 2, 8712 (2014).

Z.P. Wang, C. Li, H.J. Cho, S-C. Kung, M.A. Snyder, and W. Fan: Direct, single-step synthesis of hierarchical zeolites without secondary templating. J. Mater. Chem. A 3, 1298 (2015).

C. Wang, M. Yang, P. Tian, S.T. Xu, Y. Yang, D.H. Wang, Y.Y. Yuan, and Z.M. Liu: Dual template-directed synthesis of SAPO-34 nanosheet assemblies with improved stability in the methanol to olefins reaction. J. Mater. Chem. A 3, 5608 (2015).

J.C. Groen, L.A.A. Peffer, J.A. Moulijn, and J. Pérez-Ramírez: On the introduction of intracrystalline mesoporosity in zeolites upon desilication in alkaline medium. Microporous Mesoporous Mater. 69, 29 (2004).

J.S. Jung, J.W. Park, and G. Seo: Catalytic cracking of n-octane over alkali-treated MFI zeolites. Appl. Catal., A 288, 149 (2005).

S.K. Saxena, N. Viswanadham, and T. Sharma: Breakthrough mesopore creation in BEA and its enhanced catalytic performance in solvent-free liquid phase tert-butylation of phenol. J. Mater. Chem. A 2, 2487 (2014).

A.T. Aguayo, A.G. Gayubo, J. Ereña, R. Vivanco, and J. Bilbao: Study of the regeneration stage of the MTG process in a pseudoadiabatic fixed bed reactor. Chem. Eng. J. 92, 141 (2003).

F.J. Keil: Methanol-to-hydrocarbons: process technology. Microporous Mesoporous Mater. 29, 49 (1999).

M. Stöcker: Methanol-to-hydrocarbons: catalytic materials and their behavior. Microporous Mesoporous Mater. 29, 3 (1999).

M. Bjørgen, S. Svelle, F. Joensen, J. Nerlov, S. Kolboe, F. Bonino, L. Palumbo, S. Bordiga, and U. Olsbye: Conversion of methanol to hydrocarbons over zeolite H-ZSM-5: On the origin of the olefinic species. J. Catal. 249, 195 (2007).

Z.P. Liu, W.M. Fan, J.H. Ma, and R.F. Li: Adsorption, diffusion and catalysis of mesostructured zeolite HZSM-5. Adsorption 18, 493 (2012).

S. Lee, H. Kim, and M. Choi: Controlled decationization of X zeolite: mesopore generation within zeolite crystallites for bulky molecular adsorption and transformation. J. Mater. Chem. A 1, 12096 (2013).

J.H. Li, Y.N. Wang, W.Z. Jia, Z.W. Xi, H.H. Chen, Z.R. Zhu, and Z.H. Hu: Effect of external surface of HZSM-5 zeolite on product distribution in the conversion of methanol to hydrocarbons. J. Energy Chem. 23, 771 (2014).

D. Fan, P. Tian, X. Su, Y.Y. Yuan, D.H. Wang, C. Wang, M. Yang, L.Y. Wang, S.T. Xu, and Z.M. Liu: Aminothermal synthesis of CHA-type SAPO molecular sieves and their catalytic performance in methanol to olefins (MTO) reaction. J. Mater. Chem. A 1, 14206 (2013).

ACKNOWLEDGMENT

This work is supported by the National Natural Science Foundation of China-SinoPEC (No. U1463209), the National Natural Science Foundation of China (Nos. 21371129; 21376157; 51272169).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zheng, J., Sun, X., Du, Y. et al. Structural features of core–shell zeolite–zeolite composite and its performance for methanol conversion into gasoline and diesel. Journal of Materials Research 31, 2302–2316 (2016). https://doi.org/10.1557/jmr.2016.208

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.208