Abstract

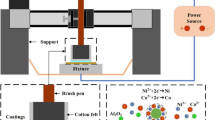

Zn–Ni alloy coatings were deposited on rolled copper foil via electro-brush plating with different micro-force. Surface morphologies, microhardness, roughness, and bending performance were characterized. Mechanisms and influences of electro–brush plating micro-force on coatings performances were investigated and revealed. With the increase of electro-brush plating micro-force, surface morphologies of coatings become smooth and dense, and the grain size was refined. Microhardness of coatings had a gradually increasing tendency when the increasing amplification was reduced. However, surface roughness of coatings as well as bending performance increased firstly and then decreased. The mechanisms of micro-force generation and action were explained by mechanics theory and principle model. Plastic deformation and work hardening are generated and performances are improved. Consequently, the performance of electro-brush plating coatings has a tight relevance with micro-force.

Similar content being viewed by others

References

J.C. Morris: Brush plating. Met. Finish. 93, 1 (1995).

D. Vanek: An update on brush plating. Met. Finish. 100, 7 (2002).

B. Wu, B.S. Xu, B. Zhang, X.D. Jing, and C.L. Liu: Automatic brush plating: An update on brush plating. Mater. Lett. 60, 13–14 (2006).

J.L. Tang, Y. Zuo, Y.M. Tang, and J.P. Xiong: Composition and corrosion resistance of palladium film on 316L stainless steel by brush plating. Trans. Nonferrous Met. Soc. China 22, 1 (2012).

J.A. Jeong, Y.J. Jeon, S.S. Kim, B.K. Kim, K.B. Chung, and H.K. Kim: Simple brush-painting of Ti-doped In2O3 transparent conducting electrodes from nano-particle solution for organic solar cells. Sol. Energy Mater. Sol. Cells 122, 241–250 (2014).

T. Chen, S. Ge, H. Liu, Q. Sun, W. Zhu, W. Yan, and J. Qi: Fabrication of low adhesive superhydrophobic surfaces using nano Cu/Al2O3 Ni–Cr composited electro-brush plating. Appl. Surf. Sci. 356, 81–90 (2015).

H.T. Liu, X.M. Wang, and H.M. Ji: Fabrication of lotus-leaf-like superhydrophobic surfaces via Ni-based nano-composite electro-brush plating. Appl. Surf. Sci. 288, 341–348 (2014).

X.L. Li, X.B. Wang, R. Gao, and L. Sun: Study of deposition patterns of plating layers in SiC/Cu composites by electro-brush plating. Appl. Surf. Sci. 257, 23 (2011).

J. Sun, L. Wang, K. Hu, J.L. Song, and X. Liu: Fabrication of superhydrophobic surfaces on copper substrates via flow plating technology. Micro Nano Lett. 10, 2 (2015).

Y.C. Qian, J. Tan, Q.Q. Liu, H.L. Yu, R.X. Xing, and H.J. Yang: Preparation, microstructure and sliding-wear characteristics of brush plated copper–nickel multilayer films. Surf. Coat. Technol. 205, 15 (2011).

Z. Zhong and S.J. Clouser: Nickel–tungsten alloy brush plating for engineering applications. Surf. Coat. Technol. 240, 380–386 (2014).

R.P. Yang, X. Cai, and Q.L. Chen: Mechanism of hydrogen desorption during palladium brush-plating. Surf. Coat. Technol. 141, 2 (2001).

W.Y. Tu, B.S. Xu, S.Y. Dong, and H.D. Wang: Electrocatalytic action of nano-SiO2 with electrodeposited nickel matrix. Mater. Lett. 60, 9–10 (2006).

B. Subramanian, S. Mohan, S. Jayakrishnan, and M. Jayachandran: Structural and electrochemical characterization of Ni nanostructure films on steels with brush plating and sputter deposition. Curr. Appl. Phys. 7, 3 (2007).

B. Jiang, B.S. Xu, S.Y. Dong, Y. Yi, and P.D. Ding: Contact fatigue behavior of nano-ZrO2/Ni coating prepared by electro-brush plating. Surf. Coat. Technol. 202, 3 (2007).

G. Dehm, B. Medres, L. Shepeleva, C. Scheu, M. Bamberger, B.L. Mordike, S. Mordike, G. Ryk, G. Halperin, and I. Etsion: Microstructure and tribological properties of Ni-based claddings on Cu substrates. Wear 225, 18–26 (1999).

ACKNOWLEDGMENT

Financial support from National Key Technology Support Program (No. 2011BAE23B02) and Fundamental Research Funds for the Central Universities (No. FRF-TP-10-002B) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Liu, X. & Shi, Z. Mechanisms and influences of electro-brush plating micro-force on coatings performances. Journal of Materials Research 31, 2337–2346 (2016). https://doi.org/10.1557/jmr.2016.191

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.191