Abstract

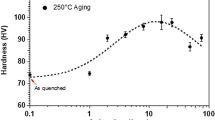

In the present work, the effect of pre-ageing temperature and time variations on the mechanical properties and electrical conductivity of the Retrogression and re-aging (RRA) treated 7050 has been investigated. The results reveal that the electronic conductivity and hardness of RRA-treated samples are sensitive to the pre-ageing tempers. The RRA-treated samples with 120 °C/2 h pre-ageing +180 °C/2 h retrogression +120 °C/24 h re-ageing temper can be tailored toward a good combination of strength and elongation, while the electrical conductivity of re-ageing samples is also higher than that of 120 °C/24 h pre-ageing RRA-treated samples. With an intermediate pre-ageing temperature of 80 °C/24 h RRA-treated samples possess a higher re-aged electronic conductivity, while no significant differences can be found between hardness of 120 °C/2 h and 120 °C/24 h pre-ageing RRA-treated samples. The variation of hardness and electronic conductivity during retrogression depends on the pre-ageing tempers. For under-aged sample, the retrogression hardness appears a stage of hardness increasing followed by a further decrease in hardness results, owing to disappearance of dissolving stage of fine GP zone and η′ phase during pre-ageing.

Similar content being viewed by others

References

Y.H. Zhao, X.Z. Liao, and Y.T. Zhu: Enhanced mechanical properties in ultrafine grained 7075 Al alloy. J. Mater. Res. 20, 288 (2005).

D. Vojtech and E. Tagiev: Casting properties of the high-strength AlZnMgCuNiSi alloys. J. Mater. Res. 18, 635 (2003).

J.P. Immarigon, R.T. Holt, A.K. Koul, L. Zhao, W. Wallace, and J.C. Beddoes: Lightweight materials for aircraft applications. Mater. Charact. 35, 41 (1995).

J.C. Williams and E.A. Starke: Progress in structural materials for aerospace systems. Acta Mater. 51, 5775 (2003).

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus, and W.S. Miller: Recent development in aluminum alloys for aerospace applications. Mater. Sci. Eng., A 280, 102 (2000).

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge: Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng., A 280, 37 (2000).

B. Liu, C.Q. Peng, R.C. Wang, X.F. Wang, and T.T. Li: Recent development and prospects for giant plane aluminum alloys. Trans. Nonferrous Met. Soc. China 20, 1705 (2010).

Y. Liu, D.M. Jiang, B.Q. Li, W.S. Yang, and J. Hu: Effect of cooling aging on microstructure and mechanical properties of an Al-Zn-Mg-Cu alloy. Mater. Des. 54, 79 (2014).

L. Xu, G.Z. Dai, X.M. Huang, J.W. Zhao, J. Han, and J.W. Gao: Foundation and application of Al–Zn–Mg–Cu alloy flow stress constitutive equation in friction screw press die forging. Mater. Des. 47, 465 (2013).

C. Sharma, D.K. Dwivedi, and P. Kumar: Effect of post weld heat treatments on microstructure and mechanical properties of friction stir welded joints of Al–Zn–Mg alloy AA7039. Mater. Des. 43, 134 (2013).

J. Li, F. Li, M. He, F. Xue, M. Zhang, and C. Wang: Indentation technique for estimating the fracture toughness of 7050 aluminum alloy with the Berkovich indenter. Mater. Des. 40, 176 (2012).

A.F. Oliveira, M.C. Barros, K.R. Cardoso, and D.N. Travessa: The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminum alloys. Mater. Sci. Eng., A 379, 321 (2004).

J.K. Parker and A.J. Ardell: Effect of retrogression and re-aging treatments on the microstructure of A1-7075-T651. Metall. Trans. 15, 1531 (1984).

F. Viana, A.M.P. Pinto, H.M.C. Santos, and A.B. Lopes: Retrogression and re-ageing of 7075 aluminium alloy: Microstructural characterization. J. Mater. Process. Technol. 93, 54 (1999).

B. Cina and M. Talianke: Retrogression and reaging and the role of dislocations in the stress corrosion of 7000-type aluminum alloys. Metall. Trans. A 20, 87 (1989).

X.J. Wu, M.D. Raizenne, W.R. Chen, C. Poon, and W. Wallace: Thirty years of retrogression and re-aging. In Brescia, Italy: In ICAS 2002 Congress (pp. 1–11).

K. Ural: A study of optimization of heat-treatment conditions in retrogression and reaging treatment of 7075-T6 aluminum alloy. J. Mater. Sci. Lett. 13, 383 (1994).

J.F. Li, N. Birbilis, C.X. Li, Z.Q. Jia, B. Cai, and Z.Q. Zheng: Influence of retrogression temperature and time on the mechanical properties and exfoliation corrosion behavior of aluminium alloy AA7150. Mater. Charact. 60, 1334 (2009).

Y.P. Xiao, Q.L. Pan, W.B. Li, X.Y. Liu, and Y.B. He. Influence of retrogression and re-aging treatment on corrosion behavior of an Al–Zn–Mg–Cu alloy. Mater. Des. 23, 2149 (2011).

M. Puiggali, A. Zielinski, J.M. Olive, E. Renauld, D. Desjardins, and M. Cid: Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu Alloy. Corrs. Sci. 40, 805 (1998).

G.J. Meng and G.S. Frankel: Effect of Cu content on corrosion behavior of 7xxx series aluminum alloys. J. Electrochem. Soc. 151, 271 (2004).

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, and B. Baroux: Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al–Zn–Mg–Cu alloy. Acta Mater. 58, 4814 (2010).

B. Sarkar, M. Marek, and E.A. Starke: The effect of copper content and heat treatment on the stress corrosion characteristics of Al–6Zn–2Mg–X Cu alloys. Metall. Trans. A 12, 1929 (1981).

W. Feng, B.Q. Xiong, Y.Q. Zhang, B.H. Zhu, H.W. Liu, and X.Q. He: Effect of heat treatment on the microstructure and mechanical properties of the spray-deposited Al–10.8Zn–2.8Mg–1.9Cu alloy. Mater. Sci. Eng., A 486, 648 (2008).

J.K. Park and A.J. Ardell: Microchemical analysis of precipitate free zones in 7075-A1 in the T6, T7 and RRA tempers. Acta Metall. Mater. 39, 591 (1991).

D.K. Xu, N. Birbilis, and P.A. Rometsch. The effect of pre-ageing temperature and retrogression heating rate on the strength and corrosion behaviour of AA7150. Corros. Sci. 54, 17 (2012).

D. Feng, X.M. Zhang, S.D. Liu, T. Wang, Z.Z. Wu, and Y.W. Guo: The effect of pre-ageing temperature and retrogression heating rate on the microstructure and properties of AA7055. Mater. Sci. Eng., A 588, 34 (2013).

M. Nicolas and A. Deschamps: Characterization and modelling of precipitate evolution in an Al–Zn–Mg alloy during non-isothermal heat treatments. Acta Mater. 51, 6077 (2003).

T. Ungár, J. Lendvai, I. Kovács, G. Groma, and E. Kovács-Csetényi: The decomposition of the solid solution state in the temperature range 20–200°C in an Al-Zn-Mg alloy. J. Mater. Sci. 14, 671 (1979).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Li, W. & Jiang, D. The effect of pre-ageing on the microstructure and properties of 7050 alloy. Journal of Materials Research 30, 3803–3810 (2015). https://doi.org/10.1557/jmr.2015.372

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.372