Abstract

Experimental observations have shown that carbon nanotubes (CNTs)/Al nanocomposites with high level ordered nanolaminates exhibit greatly improved plasticity. The increased plasticity is mainly attributed to enhanced dislocation storage capability and two-dimensional alignment of the reinforcement. Here a theoretical model is proposed with interactions between aligned CNTs and grain boundary dislocations emitted from a crack tip taken into consideration to investigate crack blunting and fracture toughness in nanocrytalline metal matrix composites (MMCs). The critical shear stress for emission of first dislocation from intersections between a long, flat crack and aligned CNTs is quantitatively characterized. The final equilibrium positions and maximum numbers of emitted dislocations for different orientation angles and microstructures of aligned reinforcement are evaluated. In addition, the dependence of enhanced fracture toughness on effective gliding distance of emitted dislocations is also determined. The results show that the existence of aligned CNTs can lead to an increase of critical crack intensity factor by 77% than that in dislocation free case under certain conditions. The model may provide a basis understanding of ductility in aligned CNTs-reinforced nanocrystalline MMCs on respective of emission and motion of dislocations.

Similar content being viewed by others

References

I.A. Ovid’ko: Review on the fracture processes in nanocrystalline materials. J. Mater. Sci. 42, 1694 (2007).

J.A. Sharon, H.A. Padilla, and B.L. Boyce: Interpreting the ductility of nanocrystalline metals 1. J. Mater. Res. 28 (12), 1539 (2013).

W.W. Gerberich, J. Michler, W.M. Mook, R. Ghisleni, F. Östlund, D.D. Stauffer, and R. Ballarini: Scale effects for strength, ductility, and toughness in “brittle” materials. J. Mater. Res. 24 (03), 898 (2011).

J.D. Kuntz, G-D. Zhan, and A.K. Mukherjee: Nanocrystalline-matrix ceramic composites for improved fracture toughness. MRS Bull. 29 (1), 22 (2004).

Y. Wu, J. Zhou, H. Liu, X. Pang, S. Zhang, Y. Wang, L. Wang, and S. Dong: The effects of intergranular sliding on the fracture toughness of nanocrystalline materials with finest grains. J. Mater. Res. 29 (09), 1086 (2014).

Y.G. Liu, J.Q. Zhou, and T.D. Shen: A combined dislocation–cohesive zone model for fracture in nanocrystalline materials. J. Mater. Res. 27 (04), 694 (2012).

Y.G. Liu, J.Q. Zhou, T.D. Shen, and D. Hui: Effects of ultrafine nanograins on the fracture toughness of nanocrystalline materials. J. Mater. Res. 26 (14), 1734 (2011).

I.A. Ovid’ko, N.V. Skiba, and A.K. Mukherjee: Nucleation of nanograins near cracks in nanocrystalline materials. Scr. Mater. 62 (6), 387 (2010).

M. Yu, Q. Fang, H. Feng, and Y. Liu: Effect of special rotational deformation on dislocation emission from a semielliptical blunt crack tip in nanocrystalline solids. J. Mater. Res. 28 (06), 798 (2013).

S. Cheng, H. Choo, Y.H. Zhao, X.L. Wang, Y.T. Zhu, Y.D. Wang, J. Almer, P.K. Liaw, J.E. Jin, and Y.K. Lee: High ductility of ultrafine-grained steel via phase transformation. J. Mater. Res. 23 (06), 1578 (2011).

Y.H. Zhao, X.Z. Liao, S. Cheng, E. Ma, and Y.T. Zhu: Simultaneously increasing the ductility and strength of nanostructured alloys. Adv. Mater. 18 (17), 2280 (2006).

Y.H. Zhao, T. Topping, J.F. Bingert, J.J. Thornton, A.M. Dangelewicz, Y. Li, W. Liu, Y. Zhu, Y. Zhou, and E.J. Lavernia: High tensile ductility and strength in bulk nanostructured nickel. Adv. Mater. 20 (16), 3028 (2008).

I.A. Ovid’ko and A.G. Sheinerman: Ductile vs. brittle behavior of pre-cracked nanocrystalline and ultrafine-grained materials. Acta Mater. 58 (16), 5286 (2010).

I.A. Ovid’ko and A.G. Sheinerman: Grain size effect on crack blunting in nanocrystalline materials. Scr. Mater. 60 (8), 627 (2009).

Y.G. Liu, J.Q. Zhou, L. Wang, S. Zhang, and Y. Wang: Grain size dependent fracture toughness of nanocrystalline materials. Mater. Sci. Eng., A 528 (13–14), 4615 (2011).

H. Feng, Q.H. Fang, L.C. Zhang, and Y.W. Liu: Effect of cooperative grain boundary sliding and migration on emission of dislocations from a crack tip in nanocrystalline materials. Mech. Mater. 61, 39 (2013).

S.V. Bobylev, A.K. Mukherjee, I.A. Ovid’ko, and A.G. Sheinerman: Effects of intergrain sliding on crack growth in nanocrystalline materials. Int. J. Plast. 26 (11), 1629 (2010).

Y.G. Liu, J.Q. Zhou, and T.D. Shen: Effect of nano-metal particles on the fracture toughness of metal–ceramic composite. Mater. Des. 45, 67 (2013).

L. Wang, J.Q. Zhou, S. Zhang, H.X. Liu, and S.H. Dong: Effect of dislocation–GB interactions on crack blunting in nanocrystalline materials. Mater. Sci. Eng., A 592, 128 (2014).

J. Ye, B.Q. Han, Z. Lee, B. Ahn, S.R. Nutt, and J.M. Schoenung: A tri-modal aluminum based composite with super-high strength. Scr. Mater. 53 (5), 481 (2005).

Y. Li, Y.H. Zhao, V. Ortalan, W. Liu, Z.H. Zhang, R.G. Vogt, N.D. Browning, E.J. Lavernia, and J.M. Schoenung: Investigation of aluminum-based nanocomposites with ultra-high strength. Mater. Sci. Eng., A 527 (1–2), 305 (2009).

J. Zhao, J-W. Jiang, L. Wang, W. Guo, and T. Rabczuk: Coarse-grained potentials of single-walled carbon nanotubes. J. Mech. Phys. Solids 71, 197 (2014).

J. Zhao, L. Lu, and T. Rabczuk: Binding energy and mechanical stability of single- and multi-walled carbon nanotube serpentines. J. Chem. Phys. 140 (20), 204704 (2014).

Q. Li and B. Tian: Compression behavior of magnesium/carbon nanotube composites. J. Mater. Res. 28 (14), 1877 (2013).

T. Kuzumaki, K. Miyazawa, H. Ichinose, and K. Ito: Processing of carbon nanotube reinforced aluminum composite. J. Mater. Res. 13, 2445 (1998).

A. Goyal, D.A. Wiegand, F.J. Owens, and Z. Iqbal: Enhanced yield strength in iron nanocomposite with in situ grown single-wall carbon nanotubes. J. Mater. Res. 21 (02), 522 (2011).

H.J. Choi, J.H. Shin, B.H. Min, J. Park, and D.H. Bae: Reinforcing effects of carbon nanotubes in structural aluminum matrix nanocomposites. J. Mater. Res. 24 (08), 2610 (2011).

D.J. Woo, J.P. Hooper, S. Osswald, B.A. Bottolfson, and L.N. Brewer: Low temperature synthesis of carbon nanotube-reinforced aluminum metal composite powders using cryogenic milling. J. Mater. Res. 29 (22), 2644 (2014).

K. Kang, G. Bae, and C. Lee: Strengthening mechanisms of multiwalled carbon nanotube-reinforced Cu nanocomposite coatings during kinetic spray consolidation. J. Mater. Res. 27 (18), 2375 (2012).

S. Dong, J. Zhou, H. Liu, and D. Qi: Computational prediction of waviness and orientation effects in carbon nanotube reinforced metal matrix composites. Comput. Mater. Sci. 101, 8 (2015).

Z.W. Xue, L.D. Wang, P.T. Zhao, S.C. Xu, J.L. Qi, and W.D. Fei: Microstructures and tensile behavior of carbon nanotubes reinforced Cu matrix composites with molecular-level dispersion. Mater. Des. 34, 298 (2012).

T. Borkar, J. Hwang, J.Y. Hwang, T.W. Scharf, J. Tiley, S.H. Hong, and R. Banerjee: Strength versus ductility in carbon nanotube reinforced nickel matrix nanocomposites. J. Mater. Res. 29 (06), 761 (2014).

H.J. Choi and D.H. Bae: Strengthening and toughening of aluminum by single-walled carbon nanotubes. Mater. Sci. Eng., A 528 (6), 2412 (2011).

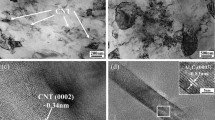

L. Jiang, Z. Li, G. Fan, L. Cao, and D. Zhang: Strong and ductile carbon nanotube/aluminum bulk nanolaminated composites with two-dimensional alignment of carbon nanotubes. Scr. Mater. 66 (6), 331 (2012).

W.A. Curtin and B.W. Sheldon: CNT-reinforced ceramics and metals. Mater. Today 7 (11), 44 (2004).

S.H. Dong, J.Q. Zhou, D. Hui, Y. Wang, and S. Zhang: Size dependent strengthening mechanisms in carbon nanotube reinforced metal matrix composites. Composites, Part A 68, 356 (2015).

M.Y. Gutkin and I.A. Ovid’ko: Dislocation mechanism of hollow fiber sliding during ceramic nanocomposite fracture. Phys. Solid State 50 (11), 2053 (2008).

N.V. Viet and W.S. Kuo: Load transfer in fractured carbon nanotubes under tension. Composites, Part B 43 (2), 332 (2012).

Y.L. Chen, B. Liu, Y. Huang, and K.C. Hwang: Fracture toughness of carbon nanotube-reinforced metal- and ceramic-matrix composites. J. Nanomater. 2011, 746029 (2011).

Y.L. Chen, B. Liu, X.Q. He, Y. Huang, and K.C. Hwang: Failure analysis and the optimal toughness design of carbon nanotube-reinforced composites. Compos. Sci. Technol. 70 (9), 1360 (2010).

C.S. Goh, J. Wei, L.C. Lee, and M. Gupta: Ductility improvement and fatigue studies in Mg-CNT nanocomposites. Compos. Sci. Technol. 68 (6), 1432 (2008).

M.Y. Gutkin and I.A. Ovid’ko: Glide of hollow fibers at the bridging stage of fracture in ceramic nanocomposites. Scr. Mater. 59 (4), 414 (2008).

S.H. Dong, J.Q. Zhou, D. Hui, X.M. Pang, Q. Wang, S. Zhang, and L. Wang: Interaction between edge dislocations and amorphous interphase in carbon nanotubes reinforced metal matrix nanocomposites incorporating interface effect. Int. J. Solids Struct. 51 (5), 1149 (2014).

C.C. Koch: Structural nanocrystalline materials: An overview. J. Mater. Sci. 42 (5), 1403 (2007).

H. Kwon, M. Estili, K. Takagi, T. Miyazaki, and A. Kawasaki: Combination of hot extrusion and spark plasma sintering for producing carbon nanotube reinforced aluminum matrix composites. Carbon 47 (3), 570 (2009).

A.L. Vasiliev, R. Poyato, and N.P. Padture: Single-wall carbon nanotubes at ceramic grain boundaries. Scr. Mater. 56 (6), 461 (2007).

S.X. Mao and M.Z. Li: Effects of dislocation shielding on interface crack initiation and growth in metal/ceramic layered materials. J. Mech. Phys. Solids 47 (11), 2351 (1999).

I.H. Lin and R. Thomson: Cleavage, dislocation emission, and shielding for cracks under general loading. Acta Metall. 34 (2), 187 (1986).

M.Y. Gutkin and A.E. Romanov: Straight edge dislocation in a thin two-phase plate I. elastic stress fields. Phys. Status Solidi A 125, 107 (1991).

P.B. Chowdhury, H. Sehitoglu, R.G. Rateick, and H.J. Maier: Modeling fatigue crack growth resistance of nanocrystalline alloys. Acta Mater. 61 (7), 2531 (2013).

J.R. Rice and R. Thomson: Ductile versus brittle behaviour of crystals. Philos. Mag. 29 (1), 73 (1974).

G.R. Irwin: Analysis of stresses and strains near the end of a crack traversing a plate. J. Appl. Mech. 24, 361 (1957).

T-Y. Zhang and J.C.M. Li: Image forces and shielding effects of an edge dislocation near a finite length crack. Acta Metall. Mater. 39 (11), 2739 (1991).

G.C. Hasson and C. Goux: Interfacial energies of tilt boundaries in aluminium. Experimental and theoretical determination. Scr. Metall. 5 (10), 889 (1971).

L.X. Shen and J. Li: Transversely isotropic elastic properties of multiwalled carbon nanotubes. Phys. Rev. B 71 (3), 035412 (2005).

Y.G. Liu, J.Q. Zhou, T.D. Shen, and D. Hui: Grain rotation dependent fracture toughness of nanocrystalline materials. Mater. Sci. Eng., A 528 (25–26), 7684 (2011).

ACKNOWLEDGMENTS

This work was supported by Key Project of Chinese Ministry of Education (211061), National Natural Science Foundation of China (10502025, 10872087, 11272143), Program for Chinese New Century Excellent Talents in university (NCET-12-0712), Ph.D. Programs Foundation of Ministry of Education of China (20133221110008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, S., Zhou, J., Hui, D. et al. Fracture toughness of nanocrystalline metal matrix composites reinforced by aligned carbon nanotubes. Journal of Materials Research 30, 3267–3276 (2015). https://doi.org/10.1557/jmr.2015.294

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.294