Abstract

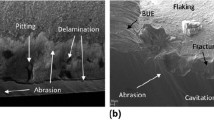

The aim of the present investigation is to identify the wear mechanisms of multilayer coated carbide tool under different machining conditions during turning of hardened AISI 4340 steel. The chemical vapor deposited multilayer coated (TiN/MT TiC,N/Al2O3) carbide tool was used. The worn surfaces of the cutting tools were examined under digital optical microscope, scanning electron microscope, and elemental analysis. The investigation results showed a strong correlation between the cutting conditions and tool wear. The cutting speed and feed rate ensure the dominant effects on the tool wear followed by the depth of cut and also the progress of tool wear were verified under different intervals of time. The flank and rake faces of the cutting tool were severely gouged by the hard particles of workpiece material exhibited abrasive wear phenomenon. Intermittently, chipping at cutting edge, notching and catastrophic failure modes were observed in continuous machining.

Similar content being viewed by others

References

A. Jorge, O. Yume, and P.Y. Kwon: Crater wear evolution in multilayer coated carbides during machining using confocal microscopy. J. Manuf. Process 9(1), 47–60 (2007).

J.S. Dureja, V.K. Gupta, V.S. Sharma, and M. Dogra: Wear mechanisms of TiN-coated CBN tool during finish hard turning of hot tool die steel. Proc. Inst. Mech. Eng., Part B 224, 553–566 (2010).

S.K. Khrais and Y.J. Lin: Wear mechanisms and tool performance of TiAlN PVD coated inserts during machining of AISI 4140 steel. Wear 262, 64–69 (2007).

D. Mari and D.R. Gonseth: A new look at carbide tool life. Wear 165, 9–17 (1993).

H.G. Prengel, W.R. Pfouts, and A.T. Santhanam: State of the art in hard coatings for carbide cutting tools. Surf. Coat. Technol. 102, 183–190 (1998).

V.C. Venkatesh, C.T. Ye, D.T. Quinto, and D.E.P. Hoy: Performance studies of uncoated, CVD coated and PVD coated carbides in turning and milling. CIRP Ann. 40, 545–551 (1991).

R. Bonetti, H. Wipraechtiger, and E. Mohn: Protective CVD coatings for the tool industry requirements for process control and equipment. Met. Powder Rep. 45, 837–843 (1990).

H.G. Prengel, W. Heinrich, G. Roder, and K.H. Wendt: CVD coatings based on medium temperature CVD Κ- and α-Al2O3. Surf. Coat. Technol. 68/69, 217–220 (1994).

J.P. Davim: Machining of Hard Materials (Springer-Verlag, London, 2011). ISBN 1849964505, 9781849964500, doi: https://doi.org/10.1007/978-1-84996-450-0.

J.A. Ghani, I.A. Choudhury, and H.H. Masjuki: Wear mechanism of TiN coated carbide and uncoated cermets tools at high cutting speed applications. J. Mater. Process. Technol. 153/154, 1067–1073 (2004).

J.A. Arsecularatne, L.C. Zhanga, and C. Montross: Wear and tool life of tungsten carbide, PCBN and PCD cutting tools. Int. J. Mach. Tool Manuf. 46, 482–491 (2006).

E. Aslan: Experimental investigation of cutting tool performance in high speed cutting of hardened X210 Cr12 cold-work tool steel (62 HRC). Mater. Des. 26, 21–27 (2005).

S.S. Cho and K. Komvopoulos: Wear mechanisms of multilayer coated cemented carbide cutting tools. J. Tribol. 119, 8–17 (1997).

K.D. Bouzakis, S. Hadjiyiannis, and G. Skordaris: The influence of the coating thickness on its strength properties and on the milling performance of PVD coated inserts. Surf. Coat. Technol. 174/175, 393–401 (2003).

K.H. Park and P.Y. Kwon: Flank wear of multi-layer coated tool. Wear 270, 771–780 (2011).

A.K. Sahoo and B. Sahoo: Experimental investigations on machinability aspects in finish hard turning of AISI 4340 steel using uncoated and multilayer coated carbide inserts. Measurement 45, 2153–2165 (2012).

I. Ciftci: Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 39, 565–569 (2006).

M.Y. Noordin, V.C. Venkatesh, and S. Sharif: Dry turning of tempered martensitic stainless tool steel using coated cermet and coated carbide tools. J. Mater. Process. Technol. 185, 83–90 (2007).

N.A. Knutsson, M.P. Johansson, L. Karlsson, and M. Oden: Machining performance and decomposition of TiAlN/TiN multilayer coated metal cutting inserts. Surf. Coat. Technol. 205, 4005–4010 (2011).

R.F. Avila, C. Godoy, A.M. Abrao, and M.M. Lima: Topographic analysis of the crater wear on TiN, Ti(C,N) and Ti,AlN coated carbide tools. Wear 265, 49–56 (2008).

F.M. Aneiro, T.C. Reginaldo, and C.B. Lincoln: Turning hardened steel using coated carbide at high cutting speeds. J. Braz. Soc. Mech. Sci. Eng. 30(2), 104–109 (2008).

E.O. Ezugwu, R.B. Silva, J.A. Bonney, and R. Machado: Evaluation of the performance of CBN when turning Ti-6Al-4V alloy with high pressure coolant supplies. Int. J. Mach. Tool Manuf. 45(9), 1009–1014 (2005).

T.H. Lee and P. Mathew: Experimental and theoretical investigation of AISI D2 hardened steel machining with varying nose radius CBN tools. Int. J. Mach. Machinabil. Mater. 2(2), 254–269 (2007).

Y. Huang and G. Dason: Tool crater wear depth modeling in CBN hard turning. Wear 258, 1455–1461 (2005).

V.P. Astakhov: The assessment of cutting tool wear. Int. J. Mach. Tool Manuf. 44(6), 637–647 (2004).

T. Tamizharasan, T. Selvaraj, and A. Noorul Haq: Analysis of tool wear and surface finish in hard turning. Int. J. Adv. Manuf. Technol. 28, 671–679 (2006).

A.S. More, W. Jiang, W.D. Brown, and A.P. Malshe: Tool wear and machining performance of CBN–TiN coated carbide inserts and PCBN compact inserts in turning AISI 4340 hardened steel. J. Mater. Process. Technol. 180, 253–262 (2006).

S.Y. Luo, Y.S. Liao, and Y.Y. Tsai: Wear characteristics in turning high hardened alloy steel by ceramic and CBN tools. J. Mater. Process. Technol. 88, 114–121 (1999).

G. Poulachon, B.P. Bandyopadhyay, I.S. Jawahir, S. Pheulpin, and S. Emmanuel: The influence of the microstructure of hardened tool steel workpiece on the wear of PCBN cutting tools. Int. J. Mach. Tool Manuf. 43, 139–144 (2003).

ACKNOWLEDGMENT

The authors are thankful to Kennametal India Ltd., Bangalore, India for providing facilities to conduct experiments and also support for the entire work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suresh, R., Basavarajappa, S. & Gaitonde, V.N. Experimental studies on the performance of multilayer coated carbide tool in hard turning of high strength low alloy steel. Journal of Materials Research 30, 3056–3064 (2015). https://doi.org/10.1557/jmr.2015.236

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.236