Abstract

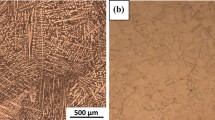

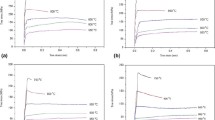

The variation of properties and evolution of microstructure of Cu–10Ni–3Al–0.8Si alloy during isothermal and aging treatment was studied. The time–temperature–property curves of the alloy were established. The nose temperature of the alloy was about 662 °C, and the alloy presented high quench sensitivity when quenched in the nose temperature zone. Discontinuous precipitation occurred when Cu–10Ni–3Al–0.8Si alloy was isothermally treated at 550 °C, and the discontinuous precipitates at the grain boundary became coarse when the isothermal temperature increased to 650 °C. Further increasing the isothermal temperature to 750 °C, cellular precipitation occurred in the alloy. Both Ni3Al precipitates with L12 ordered structure and δ-Ni2Si precipitates with DO22 ordered structure precipitated in the isothermally treated Cu–10Ni–3Al–0.8Si alloy. The orientation relationships between the precipitates and matrix were determined as \({\left[{001} \right]_{{\rm{Cu}}}}\left\| {{{\left[{001} \right]}_{{\rm{N}}{{\rm{i}}_3}{\rm{Al}}}}\left\| {{{\left[{001} \right]}_{\rm{\delta}}}} \right.} \right.\)

Similar content being viewed by others

References

C-D. Xia, Y-L. Jia, W. Zhang, Q-Y. Dong, G-Y. Xu, and M-P. Wang: Study of deformation and aging behaviors of a hot rolled-quenched Cu-Cr-Zr-Mg-Si alloy during thermomechanical treatments. Mater. Des. 39, 404 (2012).

F-A. Guo, C-J. Xiang, C-X. Yang, X-M. Cao, S-G. Mu, and Y-Q. Tang: Study of rare earth elements on the physical and mechanical properties of a Cu-Fe-P-Cr alloy. Mater. Sci. Eng., B 147, 1 (2008).

L. Yagmur: Effect of microstructure on internal friction and Young’s modulus of aged Cu-Be alloy. Mater. Sci. Eng., A 523, 65 (2009).

G-L. Xie, Q-S. Wang, X-J. Mi, B-Q. Xiong, and L-J. Peng: The precipitation behavior and strengthening of a Cu-2.0 wt% Be alloy. Mater. Sci. Eng., A 558, 326 (2012).

T. Hu, J-H. Chen, J-Z. Liu, Z-R. Liu, and C-L. Wu: The crystallographic and morphological evolution of the strengthening precipitates in Cu-Ni-Si alloys. Acta Mater. 61, 1210 (2012).

J-I. Pérez-Landazábal, V. Recarte, M-L. Nó, and J-J. San: Determination of the order in γ1 intermetallic phase in Cu-Al-Ni shape memory alloys. Intermetallics 11 (9), 927 (2003).

E. Donoso, R. Espinoza, M-J. Diànez, and J-M. Criado: Microcalorimetric study of the annealing hardening mechanism of a Cu-2.8Ni-1.4Si (at%) alloy. Mater. Sci. Eng., A 56, 612 (2012).

R. Monzen and C. Watanabe: Microstructure and mechanical properties of Cu-Ni-Si alloys. Mater. Sci. Eng., A 483–484, 117 (2010).

S. Suzuki, N. Shibutani, K. Mimura, M. Isshiki, and Y. Waseda: Improvement in strength and electrical conductivity of Cu-Ni-Si alloys by aging and cold rolling. J. Alloys Compd. 417, 116 (2006).

D. Li, P. Franke, S. Fürtauer, D. Cupid, and H. Flandorfer: The Cu-Sn phase diagram part II: New thermodynamic assessment. Intermetallics 34, 148 (2013).

S. Satoshi, I. Mikio, S. Shigeo, W. Kazuaki, and T. Takayuki: Extraction of precipitates from age-hardenable Cu-Ti alloys. Mater. Charact. 82, 23 (2013).

S. Nestorović, I. Marković, and D. Marković: Influence of thermomechanical treatment on the hardening mechanisms and structural changes of a cast Cu-6.6 wt.%Ag alloy. Mater. Des. 31, 1644 (2010).

S. Shiro and N. Koji: On quench sensitivity of Cu-Cr alloys. J. Jpn. Inst. Met. Mater. 33, 1155 (1969).

X-M. Zhang, W-J. Liu, S-D. Liu, and M-Z. Zhou: Effect of processing parameters on quench sensitivity of an AA7050 sheet. Mater. Sci. Eng., A 528, 795 (2011).

S-D. Liu, W-J. Liu, Y. Zhang, X-M. Zhang, and Y-L. Deng: Effect of microstructure on the quench sensitivity of AlZnMgCu alloys. J. Alloys Compd. 507, 53 (2010).

S. Hisashi and K. Motohiro: The T-T-T curve in Cu-Cr alloy. J. Jpn. Inst. Met. Mater. 35, 434 (1971).

Q. Lei, Z. Li, A-Y. Zhu, W-T. Qiu, and S-Q. Liang: The transformation behavior of Cu-8.0Ni-1.8Si-0.6Sn-0.15Mg alloy during isothermal heat treatment. Mater. Charact. 62, 904 (2011).

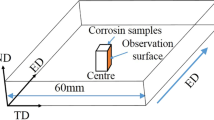

L-N. Shen, Z. Li, Z-M. Zhang, Q-Y. Dong, Z. Xiao, Q. Lei, and W-T. Qiu: Effects of silicon and thermo-mechanical process on microstructure and properties of Cu-10Ni-3Al-0.8Si alloy. Mater. Des. 62, 265 (2014).

F-J. Blatt: Effect of point imperfections on the electrical properties of copper. I. Conductivity. Phys. Rev. 99 (6), 1708 (1955).

Q. Lei, Z. Li, T. Xiao, Y. Pang, Z-Q. Xiang, W-T. Qiu, and Z. Xiao: A new ultrahigh strength Cu-Ni-Si alloy. Intermetallics 42, 77 (2013).

W-O. Alexander: Copper-rich nickel-aluminium-copper alloys. Part II—The constitution of the copper-nickel-rich alloys. J. Inst. Met. 30, 425 (1938).

Y-R. Cho, Y-H. Kim, and T-D. Lee: Precipitation hardening and recrystallization in Cu-4% to 7% Ni-3% Al alloys. J. Mater. Sci. 26, 2879 (1991).

J-S. Robinson, R-L. Cudd, D-A. Tanner, and G-P. Dolan: Quench sensitivity and tensile property inhomogeneity in 7010 forgings. J. Mater. Process. Technol. 119, 261 (2001).

T. Torma, E-C. Kovács, T. Turmezey, T. Ungár, and I. Kovács: Hardening mechanisms in Al-Sc alloys. J. Mater. Sci. 24, 3924 (1989).

ACKNOWLEDGMENTS

The authors are pleased to acknowledge the financial supply supported by the National Natural Science Foundation of China (51271203), Hunan Provincial Natural Science Foundation of China (11JJ2025), and the Nonferrous Metals Science Foundation of HNG-CSU (YSZN2013CL06).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, L., Li, Z., Dong, Q. et al. Microstructure evolution and quench sensitivity of Cu–10Ni–3Al–0.8Si alloy during isothermal treatment. Journal of Materials Research 30, 736–744 (2015). https://doi.org/10.1557/jmr.2015.12

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.12