Abstract

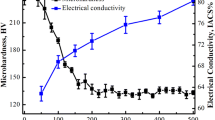

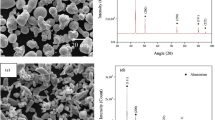

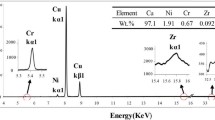

In the present work, Cu–Al alloys were processed by surface mechanical attrition treatment (SMAT) under both room and liquid nitrogen temperature (LNT) conditions. In contrast to room temperature (RT) SMAT, dynamic recovery and recrystallization were largely suppressed during the LNT process. A gradient microstructure was obtained due to the gradient strain and strain rate impacted onto the sample. Microhardness measurement showed that the hardness values gradually decreased from the top surface to the central region. The local hardness of the top surface layer of the LNT and RT SMAT Cu–4.5% Al samples reached maximum values of 1.52 and 1.28 GPa, respectively. The Cu–4.5% Al alloy exhibited an improved yield strength of ∼496 MPa and a higher ductility (compared with literature data of Cu–Al alloys synthesized traditional severe plastic deformation methods) of 15.4% after the LNT SMAT process. A brittle-ductile failure pattern was easily distinguished after fracture. Moreover, the LNT SMAT is a low-cost process with high productivity and can be applied to various types of metallic production.

Similar content being viewed by others

REFERENCES

R. Jahadi, M. Sedighi, and H. Jahed: ECAP effect on the micro-structure and mechanical properties of AM30 magnesium alloy. Mater. Sci. Eng., A 593, 178 (2014).

X.H. An, Q.Y. Lin, S.D. Wu, and Z.F. Zhang: Microstructural evolution and shear fracture of Cu-16 at.% Al alloy induced by equal channel angular pressing. Mater. Sci. Eng., A 527, 4510 (2010).

A.P. Zhilyaev, A.A. Gimazov, G.I. Raab, and T.G. Langdon: Using high-pressure torsion for the cold-consolidation of copper chips produced by machining. Mater. Sci. Eng., A 486, 123 (2008).

Y.S. Li, N.R. Tao, and K. Lu: Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater. 56, 230 (2008).

Y.H. Zhao, J.F. Bingert, X.Z. Liao, B.Z. Cui, K. Han, A.V. Sergueeva, A.K. Mukherjee, R.Z. Valiev, T.G. Langdon, and Y.T. Zhu: Simultaneously increasing the ductility and strength of ultra-fine-grained pure copper. Adv. Mater. 18, 2949 (2006).

E. Ma: Instabilities and ductility of nanocrystalline and ultrafine-grained metals. Scr. Mater. 49, 663 (2003).

C.C. Koch: Optimization of strength and ductility in nanocrystalline and ultrafine grained metals. Scr. Mater. 49, 657 (2003).

K. Lu and J. Lu: Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng., A 375, 38 (2004).

Y.M. Wang, K. Wang, D. Pan, K. Lu, K.J. Hemker, and E. Ma: Microsample tensile testing of nanocrystalline copper. Scr. Mater. 48, 1581 (2003).

K.Y. Zhu, A. Vassel, F. Brisset, K. Lu, and J. Lu: Nanostructure formation mechanism of α-titanium using SMAT. Acta Mater. 52, 4101 (2004).

M. Wen, G. Liu, J.F. Gu, W.M. Guan, and J. Lu: The tensile properties of titanium processed by surface mechanical attrition treatment. Surf. Coat. Technol. 202, 4728 (2008).

N.R. Tao, Z.B. Wang, W.P. Tong, M.L. Sui, J. Lu, and K. Lu: An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 50, 4603 (2002).

Z.B. Wang, J. Lu, and K. Lu: Wear and corrosion properties of a low carbon steel processed by means of SMAT followed by lower temperature chromizing treatment. Surf. Coat. Technol. 201, 2796 (2006).

K.A. Darling, M.A. Tschopp, A.J. Roberts, J.P. Ligda, and L.J. Kecskes: Enhancing grain refinement in polycrystalline materials using surface mechanical attrition treatment at cryogenic temperatures. Scr. Mater. 69, 461 (2013).

A. Rohatgi, K.S. Vecchio, and G.T. Gray, III: A metallographic and quantitative analysis of the influence of stacking fault energy on shock-hardening in Cu and Cu–Al alloys. Acta Mater. 49, 427 (2001).

K. Wang, N.R. Tao, G. Liu, J. Lu, and K. Lu: Plastic strain-induced grain refinement at the nanometer scale in copper. Acta Mater. 54, 5281 (2006).

J.L. Hay and G.M. Pharr: Instrumented indentation testing. In ASM Handbook, Vol. 8, (ASM International, Ohio, 2000); p. 232.

L. Waltz, D. Retraint, A. Roos, and P. Olier: Combination of surface nanocrystallization and co-rolling: Creating multilayer nanocrystalline composites. Scr. Mater. 60, 21 (2009).

L. Waltz, D. Retraint, A. Roos, P. Olier, and J. Lu: High strength nanocrystallized multilayered structure obtained by SMAT and co-rolling. Mater. Sci. Forum 614, 249 (2009).

B.Z. Cai, Y. Long, C. Wen, Y.L. Gong, C.J. Li, J.M. Tao, and X.K. Zhu: Role of stacking fault energy and strain rate in strengthening of Cu and Cu–Al alloys. J. Mater. Res. 29, 1747 (2014).

Y.H. Zhao, Z. Horita, T.G. Langdon, and Y.T. Zhu: Evolution of defect structures during cold rolling of ultrafine-grained Cu and Cu–Zn alloys: Influence of stacking fault energy. Mater. Sci. Eng., A 474, 342 (2008).

Z.J. Zhang, Q.Q. Duan, X.H. An, S.D. Wu, G. Yang, and Z.F. Zhang: Microstructure and mechanical properties of Cu and Cu–Zn alloys produced by equal channel angular pressing. Mater. Sci. Eng., A 528, 4259 (2011).

T.D. Shen and C.C. Koch: Formation and hardening effects in nanocrystalline Ti-N alloys prepared by mechanical alloying. Acta Mater. 44, 751 (1996).

J.Y. Guo, K. Wang, and L. Lu: Tensile properties of Cu with deformation twins induced by SMAT. J. Mater. Sci. Technol. 22, 6 (2006).

X.L. Wu, P. Jiang, L. Chen, J.F. Zhang, F.P. Yuan, and Y.T. Zhu: Synergetic strengthening by gradient structure. Mater. Res. Lett. 2, 185–191 (2014).

J.W. Tian, K. Dai, J.C. Villegas, L. Shaw, P.K. Lian, D.L. Klarstrom, and A.L. Ortiz: Tensile properties of a nickel-base alloy subjected to surface severe plastic deformation. Mater. Sci. Eng., A 493, 176 (2008).

J.G. Li, M. Umemoto, Y. Todaka, and K. Tsuchiya: Role of strain gradient on the formation of nanocrystalline structure produced by severe plastic deformation. Acta Mater. 55, 1397 (2007).

Y.M. Wang and E. Ma: Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 52, 1699 (2004).

V. Subramanya Sarma, J. Wang, W.W. Jian, A. Kauffmann, H. Conrad, J. Freudenberger, and Y.T. Zhu: Role of stacking fault energy in strengthening due to cryo-deformation of FCC metals. Mater. Sci. Eng., A 527, 7624 (2010).

S. Qu, X.H. An, H.J. Yang, C.X. Huang, G. Yang, Q.S. Zang, Z.G. Wang, S.D. Wu, and Z.F. Zhang: Microstructural evolution and mechanical properties of Cu–Al alloys subjected to equal channel angular pressing. Acta Mater. 57, 1586 (2009).

X.H. An, S.D. Wu, Z.G. Wang, and Z.F. Zhang: Enhanced cyclic deformation responses of ultrafine-grained Cu and nanocrystalline Cu–Al alloys. Acta Mater. 74, 200 (2014).

J.L. Ning and D. Wang: Concurrent high strength and high ductility in isotropic bulk Cu-Al alloy with three-dimensional nano-twinned structure. J. Alloys Compd. 514, 214 (2012).

X.Y. San, X.G. Liang, L.P. Cheng, L. Shen, and X.K. Zhu: Effect of stacking fault energy on mechanical properties of ultrafine-grain Cu and Cu–Al alloy processed by cold-rolling. Trans. Nonferrous Met. Soc. China 22, 819 (2012).

X.H. An, Q.Y. Lin, S.D. Wu, Z.F. Zhang, R.B. Figueiredo, N. Gao, and T.G. Langdon: The influence of stacking fault energy on the mechanical properties of nanostructured Cu and Cu–Al alloys processed by high-pressure torsion. Scr. Mater. 64, 954 (2011).

X.H. An, S.D. Wu, Z.F. Zhang, R.B. Figueiredo, N. Gao, and T.G. Langdon: Enhanced strength-ductility synergy in nanostructured Cu and Cu–Al alloys processed by high-pressure torsion and subsequent annealing. Scr. Mater. 66, 227 (2012).

Y. Zhang, N.R. Tao, and K. Lu: Effects of stacking fault energy, strain rate and temperature on microstructure and strength of nanostructured Cu–Al alloys subjected to plastic deformation. Acta Mater. 59, 6048 (2011).

V. Subramanya Sarma, K. Sivaprasad, D. Sturm, and M. Heilmaier: Microstructure and mechanical properties of ultra fine grained Cu–Zn and Cu–Al alloys produced by cryorolling and annealing. Mater. Sci. Eng., A 489, 253 (2008).

ACKNOWLEDGMENT

The authors wish to acknowledge the assistance and support of the National Natural Science Foundation of China (Grant No. 50874056).

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributing Editor: Jürgen Eckert

Rights and permissions

About this article

Cite this article

Sun, L., Cai, B., Wen, C. et al. The role of temperature in the strengthening of Cu–Al alloys processed by surface mechanical attrition treatment. Journal of Materials Research 30, 1670–1677 (2015). https://doi.org/10.1557/jmr.2015.112

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.112