Abstract

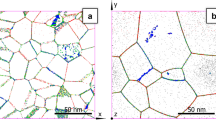

This research is devoted to the study of the effect of grain size and structural disorders on the melting behavior of Al nanocrystals under nonequilibrium conditions. The results indicate that Tm is constant and similar to Tm of perfect crystal for nanocrystals of 14 nm and higher. But, by a decrease in the grain size, Tm is significantly reduced. In addition, by further decrease in the size of the grain up to about three times the value of Al-lattice parameter, the behavior of the melt will be similar to the amorphous phase. Since it seems that these behaviors are related to high percentage of grain boundaries in nanocrystalline materials, the structural disorders of the atoms in different regions of nanocrystalline samples are separately studied during heating. The results show that premelting of boundary regions causes the melting process of nanostructure materials to be done within one temperature limit instead of at one temperature point.

Similar content being viewed by others

REFERENCES

F.G. Shi: Size dependent thermal vibrations and melting in nanocrystals. J. Mater. Res. 9, 1307 (1994).

X.J. Liu, L.W. Yang, Z.F. Zhou, P.K. Chu, and C.Q. Sun: Inverse Hall-Petch relationship in the nanostructured TiO2: Skin-depth energy pinning versus surface preferential melting. J. Appl. Phys. 108, 073503 (2010).

L. Zhou, X. Wei, and N. Zhou: Nanoscale effects of NiCl2 nanostructures. Comput. Mater. Sci. 30, 314 (2004).

M.L. Liao: Influences of film thickness and surface orientation on melting behaviors of copper nanofilms. J. Mater. Res. 14, 535 (2014).

Z. Zhang, X.X. Lu, and Q. Jiang: Finite size effect on melting enthalpy and melting entropy of nanocrystals. Phys. B 270, 249 (1999).

A.K. Schaper, F. Phillipp, and H. Hou: Melting behavior of copper nanocrystals encapsulated in onion-like carbon cages. J. Mater. Res. 20, 1844 (2005).

Q.S. Mei, and K. Lu: Melting and superheating of crystalline solids: From bulk to nanocrystals. Prog. Mater. Sci. 52, 1175 (2007).

A. Moita, S. Kim, J. Houze, B. Jelinek, S.G. Kim, S.J. Park, R.M. German, and M.F. Horstemeyer: Melting tungsten nanoparticles: A molecular dynamics study. J. Phys. D: Appl. Phys. 41, 185406 (2008).

Y. Shibuta and T. Suzuki: Melting and solidification point of fcc-metal nanoparticles with respect to particle size: A molecular dynamics study. Chem. Phys. Lett. 498, 323 (2010).

W. Luo, K. Su, K. Li, G. Liao, N. Hu, and M. Jia: Substrate effect on the melting temperature of gold nanoparticles. J. Chem. Phys. 136, 234704 (2012).

J.Q. Broughton and G.H. Gilmer: Grain boundary shearing as a test for interface melting. Modell. Simul. Mater. Sci. Eng. 6, 87 (1988).

T. Wang, F.X. Zhou, and Y.W. Liu: Influence of grain boundary on melting. Chin. Phys. Lett. 18, 1242 (2001).

P. Keblinski: High temperature structure and properties of grain boundaries—Insights obtained from atomic level simulations. Acta Phys. Pol. A 102, 123 (2002).

P.L. Williams and Y. Mishin: Thermodynamics of grain boundary premelting in alloys. II Atomistic simulation. Acta Mater. 57, 3786 (2009).

L.B. Han, Q. An, R.S. Fu, L. Zheng, and S.N. Luo: Local and bulk melting of Cu at grain boundaries. Phys. B: Condens. Matter 405, 748 (2010).

A.M. He, S. Duan, J.L. Shao, P. Wang, and C. Qin, Atomistic simulations of shock induced melting of bicrystal copper with twist grain boundary. J. Appl. Phys. 112, 103516 (2012).

M.I. Mendelev, M.J. Kramer, C.A. Becker, and M. Asta: Analysis of semi-empirical interatomic potentials appropriate for simulation of crystalline and liquid Al and Cu. Philos. Mag. 88, 1723 (2007).

S. Xiao, W. Hu, and J. Yang: Melting behaviors of nanocrystalline Ag. J. Phys. Chem. B 109, 20339 (2005).

S.S. Dalgic and U. Domekeli: Melting properties of tin nanoparticles by molecular dynamics simulation. J. Optoelectron. Adv. Mater. 11, 2126 (2009).

Y.Y. Han, J. Shuai, H.M. Lu, and X.K. Meng: Size and dimensionality dependent thermodynamic properties of ice nanocrystals. J. Phys. Chem. B 116, 1651 (2012).

J. Chen, L. Ouyang, and W.Y. Ching: Molecular dynamics simulation of Y-doped Σ37 grain boundary in alumina. Acta Mater 53, 4111 (2005).

P. Puri and V. Yang: Effect of particle size on melting of aluminum at nano scales. J. Phys. Chem. C 111, 11776 (2007).

J.R. Morris and X. Song: The melting lines of model systems calculated from coexistence simulations. J. Chem. Phys. 116, 9352 (2002).

F. Delogu: Melting behavior of a pentagonal Au nanotube. Nanotechnology 18, 325706 (2007).

Y. Shibuta and T. Suzuki: Melting and nucleation of iron nanoparticles: A molecular dynamics study. Chem. Phys. Lett. 445, 265 (2007).

E.C. Neyts and A. Bogaerts: Numerical study of the size dependent melting mechanisms of nickel nanoclusters. J. Phys. Chem. C 113, 2771 (2009).

S. Yip: Handbook of Materials Modeling-Part B (Springer, New York, 2005).

Z.H. Jin, H.W. Sheng and K. Lu: Melting of Pb clusters without free surfaces. Phys. Rev. B 60, 141 (1999).

Z.H. Jin, P. Gumbsch, K. Lu, and E. Ma: Melting mechanism at the limit of superheating. Phys. Rev. Lett. 87, 055703 (2001).

C.K. Mills: Recommended Values of Thermophysical Properties for Selected Commercial Alloys (Woodhead pub, Cambridge, England, 2002).

S. Xiao, W. Hu, and J. Yang: Melting temperature: From nanocrystalline to amorphous phase. J. Chem. Phys. 125, 184504 (2006).

T. Xu and M. Li: Topological and statistical properties of a constrained Voronoi tessellation. Philos. Mag. 89, 349 (2009).

M. Li and T. Xu: Topological and atomic scale characterization of grain boundary networks in polycrystalline and nanocrystalline materials. Prog. Mater. Sci. 56, 864 (2001).

ACKNOWLEDGMENTS

This study has been carried out in the Particulate Materials Research Groups (Department of Materials Engineering, Isfahan University of Technology) and National High Performance Computer Center (http://nhpcc.iut.ac.ir). The authors are grateful for their support for this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributing Editor: Susan B. Sinnott

Rights and permissions

About this article

Cite this article

Noori, Z., Panjepour, M. & Ahmadian, M. Study of the effect of grain size on melting temperature of Al nanocrystals by molecular dynamics simulation. Journal of Materials Research 30, 1648–1660 (2015). https://doi.org/10.1557/jmr.2015.109

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.109