Abstract

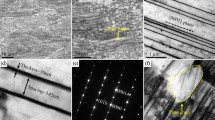

Titanium carbide (TiC) twins are believed to be extremely unstable because of their high twin boundary energy. Here, we report that TiC twins are always presented in platelets with dimensions of 2–3 µm in length and less than 300 nm in width. In-depth microstructural characterizations by high-resolution transmission electron microscopy demonstrate that Al atoms at the twin boundary play a decisive role in stabilizing TiC twins. With different amounts of Al, perfect and defective TiC twins are formed. For perfect twins, three types of twin boundaries can be formed depending on the amount of remaining Al at the twin boundary. With inadequate Al, the TiC twins become defective with certain degrees of deviation from the perfect twin orientation. Based on a detailed analysis of the microstructure of the twin boundaries, a mechanism for the formation and stabilization of TiC twins is proposed.

Similar content being viewed by others

References

S.D. Luo, Q. Li, J. Tian, C. Wang, M. Yan, G.B. Schaffer, and M. Qian: Self-assembled, aligned TiC nanoplatelet-reinforced titanium composites with outstanding compressive properties. Scripta Mater. 69 (1), 29 (2013).

M. Hsu, M. Meyers, and A. Berkowitz: Synthesis of nanocrystalline titanium carbide by spark erosion. Scripta Metall. Mater. 32 (6), 805 (1995).

D. Gu, G. Meng, C. Li, W. Meiners, and R. Poprawe: Selective laser melting of TiC/Ti bulk nanocomposites: Influence of nanoscale reinforcement. Scripta Mater. 67 (2), 185 (2012).

M. Sherif El-Eskandarany: Structure and properties of nanocrystalline TiC full-density bulk alloy consolidated from mechanically reacted powders. J. Alloys Comp. 305 (1), 225 (2000).

A. Sen, T. Kar, and S.K. Pradhan: One step quickest mechanosynthesis of nanocrystalline Ti0.9Si0.1C and its microstructure characterization. J. Alloys Comp. 557 (0), 47 (2013).

K. Lu: The future of metals. Science 328 (5976), 319 (2010).

Y. Tian, B. Xu, D. Yu, Y. Ma, Y. Wang, Y. Jiang, W. Hu, C. Tang, Y. Gao, K. Luo, Z. Zhao, L.M. Wang, B. Wen, J. He, and Z. Liu: Ultrahard nanotwinned cubic boron nitride. Nature 493 (7432), 385 (2013).

I. Gutierrez-Urrutia and D. Raabe: Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 60 (16), 5791 (2012).

J. Zhang and Y.C. Zhou: Microstructure, mechanical, and electrical properties of Cu–Ti3AlC2 and in situ Cu–TiCx composites. J. Mater. Res. 23 (4), 924 (2008).

R. Yu, Q. Zhan, L.L. He, Y.C. Zhou, and H.Q. Ye: Si-induced twinning of TiC and formation of Ti3SiC2 platelets. Acta Mater. 50 (16), 4127 (2002).

R. Yu, L.L. He, and H.Q. Ye: Effects of Si and Al on twin boundary energy of TiC. Acta Mater. 51 (9), 2477 (2003).

W.T. Hu, S.C. Liu, B. Wen, J.Y. Xiang, F.S. Wen, B. Xu, J.L. He, D.L. Yu, Y.J. Tian, and Z.Y. Liu: {111}-specific twinning structures in nonstoichiometric ZrC0.6 with ordered carbon vacancies. J. Appl. Crystallogr. 46 (1), 43 (2013).

H. Zhang, X.H. Wang, Z.J. Li, M.Y. Liu, and Y.C. Zhou: A novel Ni2AlTi-containing composite with excellent wear resistance and anomalous flexural strength. Mater. Sci. Eng., A 597 (0), 70 (2014).

B.J. Kooi, M. Kabel, A.B. Kloosterman, and J.T.M. De Hosson: Reaction layers around SiC particles in Ti: an electron microscopy study. Acta Mater. 47 (10), 3105 (1999).

F.R. Chien, S.R. Nutt, and D. Cummings: Defect structures in single crystal TiC. Philos. Mag. A 68 (2), 325 (1993).

J. Venables: Stacking faults in TiC. Phys. Status Solidi B 15 (1), 413 (1966).

J. Zhang, J.Y. Wang, and Y.C. Zhou: Structure stability of Ti3AlC2 in Cu and microstructure evolution of Cu–Ti3AlC2 composites. Acta Mater. 55 (13), 4381 (2007).

Y.C. Zhou, Z.M. Sun, and B.H. Yu: Microstructure of Ti3SiC2 prepared by the in-situ hot pressing/solid–liquid reaction process. Z. Metallkd. 91 (11), 937 (2000).

Y.C. Zhou and Z.M. Sun: Crystallographic relations between Ti3SiC2 and TiC. Mater. Res. Innovat. 3 (5), 286 (2000).

X.H. Wang and Y.C. Zhou: Solid–liquid reaction synthesis of layered machinable Ti3AlC2 ceramic. J. Mater. Chem. 12 (3), 455 (2002).

Z.J. Lin, M.J. Zhuo, Y.C. Zhou, M.S. Li, and J.Y. Wang: Microstructural characterization of layered ternary Ti2AlC. Acta Mater. 54 (4), 1009 (2006).

U. Wolf, F. Ernst, T. Muschik, M.W. Finnis, and H.F. Fischmeister: The influence of grain boundary inclination on the structure and energy of ∑ = 3 grain boundaries in copper. Philos. Mag. A 66 (6), 991 (1992).

L. Liu, J. Wang, S.K. Gong, and S.X. Mao: High resolution transmission electron microscope observation of zero-strain deformation twinning mechanisms in Ag. Phys. Rev. Lett. 106 (17), 175504 (2011).

J. Wang, O. Anderoglu, J.P. Hirth, A. Misra, and X. Zhang: Dislocation structures of sigma 3{112} twin boundaries in face centered cubic metals. Appl. Phys. Lett. 95 (2), 021908 (2009).

J. Bezares, S. Jiao, Y. Liu, D. Bufford, L. Lu, X. Zhang, Y. Kulkarni, and R.J. Asaro: Indentation of nanotwinned fcc metals: implications for nanotwin stability. Acta Mater. 60 (11), 4623 (2012).

V.Y. Markiv, V.V. Burnashova, and V.R. Riabov: A study of the Ti–Fe–Al, Ti–Ni–Al, and Ti–Cu–Al systems. Metallofizika 46 (46), 103 (1973).

K. Zeng, R. Schmid-Fetzer, B. Huneau, P. Rogl, and J. Bauer: The ternary system Al-Ni-Ti part II: thermodynamic assessment and experimental investigation of polythermal phase equilibria. Intermetallics 7 (12), 1347 (1999).

J.P. Buban, K. Matsunaga, J. Chen, N. Shibata, W.Y. Ching, T. Yamamoto, and Y. Ikuhara: Grain boundary strengthening in alumina by rare earth impurities. Science 311 (5758), 212 (2006).

Z. Wang, M. Saito, K.P. McKenna, L. Gu, S. Tsukimoto, A.L. Shluger, and Y. Ikuhara: Atom-resolved imaging of ordered defect superstructures at individual grain boundaries. Nature 479 (7373), 380 (2011).

Y.M. Chiang, A.F. Henriksen, W.D. Kingery, and D. Finello: Characterization of grain-boundary segregation in MgO. J. Am. Ceram. Soc. 64 (7), 385 (1981).

R.J. Kerans, K.S. Mazdiyasni, R. Ruh, and H.A. Lipsitt: Solubility of metals in substoichiometric TiC1−x. J. Am. Ceram. Soc. 67 (1), 34 (1984).

N. Shibata, S.J. Pennycook, T.R. Gosnell, G.S. Painter, W.A. Shelton, and P.F. Becher: Observation of rare-earth segregation in silicon nitride ceramics at subnanometre dimensions. Nature 428 (6984), 730 (2004).

A. Varschavsky and E. Donoso: The kinetics of disperse order development in α-CuAl alloys. Metall. Trans. A 14 (4), 875 (1983).

F.R. Hensel and E.I. Larsen: Age-hardening copper–titanium alloys. Trans. Am. Inst. Min. Metall. Eng. 99, 55 (1932).

M.V. Itkin and O.A. Shmatko: On the temperature-concentration bound of cellular decomposition in Cu–Ti system. Phys. Met. 4 (4), 806 (1982).

H. Okamoto: Cu–Ti (copper–titanium). J. Phase Equilib. 23 (6), 549 (2002).

J.F. Nie, Y.M. Zhu, J.Z. Liu, and X.Y. Fang: Periodic segregation of solute atoms in fully coherent twin boundaries. Science 340 (6135), 957 (2013).

H. Zhang, X.H. Wang, Y.H. Ma, L.C. Sun, L.Y. Zheng, and Y.C. Zhou: Crystal structure determination of nanolaminated Ti5Al2C3 by combined techniques of XRPD, TEM and ab initio calculations. J. Adv. Ceram. 1 (4), 268 (2012).

ACKNOWLEDGMENT

This work is supported by the Chinese Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Wang, X., Li, Z. et al. Al stabilized TiC twinning platelets. Journal of Materials Research 29, 1113–1121 (2014). https://doi.org/10.1557/jmr.2014.80

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.80