Abstract

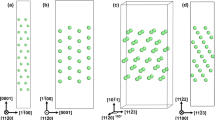

Hot-rolled Mg–Zn–Ca alloy, followed by annealing, shows high formability at room temperature because of the reduced intensity of the basal texture. [Y. Chino et al., Mater. Trans. 51, 818 (2010).] In the present work, microstructures of the as-rolled Mg–Zn–Ca alloy were investigated using electron backscattered secondary diffraction and transmission electron microscopy. In addition, first-principles calculations were performed to investigate the twinnability of the Mg–Zn–Ca alloy. The microstructural investigations revealed that fine \({\rm{\{}}10\bar 12{\rm{\}}}\) twins and local fine-grained microstructures were formed. It is therefore suggested that the fine twins induce this local fine-grained microstructure, which become the nuclei for recrystallization during annealing. As a result, the intensity of the basal texture is reduced. Calculations revealed that the \({\rm{\{}}10\bar 12{\rm{\}}}\) twinnability is enhanced by the addition of Ca because of the increased unstable stacking fault energy (γus) and decreased unstable twin fault energy (γut).

Similar content being viewed by others

References

M. Hakamada, T. Furuta, Y. Chino, Y. Chen, H. Kusuda, and M. Mabuchi: Life cycle inventory study on magnesium alloy substitution in vehicles. Energy 32, 1352 (2007).

H. Yoshinaga and R. Horiuchi: Deformation mechanisms in magnesium single crystals compressed in the direction parallel to hexagonal axis. Trans. Jpn. Inst. Met. 4, 1 (1963).

Y. Chino, M. Mabuchi, R. Kishihara, H. Hosokawa, Y. Yamada, C.E. Wen, K. Shimojima, and H. Iwasaki: Mechanical properties and press formability at room temperature of AZ31 Mg alloy processed by single roller drive rolling. Mater. Trans. 43, 2554 (2002).

X. Huang, K. Suzuki, and N. Saito: Textures and stretch formability of Mg–6Al–1Zn magnesium alloy sheets rolled at high temperatures up to 793 K. Scr. Mater. 60, 651 (2009).

X. Huang, K. Suzuki, Y. Chino, and M. Mabuchi: Improvement of stretch formability of Mg–3Al–1Zn alloy sheet by high temperature rolling at finishing pass. J. Alloys Compd. 509, 7579 (2011).

S.H. Kim, B.S. You, C.D. Yim, and Y.M. Seo: Texture and microstructure changes in asymmetrically hot rolled AZ31 magnesium alloy sheets. Mater. Lett. 59, 3876 (2005).

H. Watanabe, T. Mukai, and K. Ishikawa: Effect of temperature of differential speed rolling on room temperature mechanical properties and texture in an AZ31 magnesium alloy. J. Mater. Process. Technol. 182, 644 (2007).

Y.Q. Cheng, Z.H. Chen, and W.J. Xia: Drawability of AZ31 magnesium alloy sheet produced by equal channel angular rolling at room temperature. Mater. Charact. 58, 617 (2007).

X. Huang, K. Suzuki, A. Watazu, I. Shigematsu, and N. Saito: Effects of thickness reduction per pass on microstructure and texture of Mg–3Al–1Zn alloy sheet processed by differential speed rolling. Scr. Mater. 60, 964 (2009).

H. Li, E. Hsu, J. Szpunar, H. Utsunomiya, and T. Sakai: Deformation mechanism and texture and microstructure evolution during high-speed rolling of AZ31B Mg sheets. J. Mater. Sci. 43, 7148 (2008).

Y. Chino, K. Sassa, and M. Mabuchi: Tensile properties and stretch formability of Mg-1.5 mass%-0.2 mass%Ce sheet rolled at 723 K. Mater. Trans. 49, 1710 (2008).

Y. Chino, K. Sassa, and M. Mabuchi: Texture and stretch formability of Mg-1.5 mass%Zn-0.2 mass%Ce alloy rolled at different rolling temperatures. Mater. Trans. 49, 2916 (2008).

Y. Chino, K. Sassa, and M. Mabuchi: Texture and stretch formability of a rolled Mg–Zn alloy containing dilute content of Y. Mater. Sci. Eng., A 513–514, 394 (2009).

D.H. Kang, D.W. Kim, S. Kim, G.T. Bae, K.H. Kim, and N.J. Kim: Relationship between stretch formability and work-hardening capacity of twin-roll cast Mg alloys at room temperature. Scr. Mater. 61, 768 (2009).

H. Yan, R.S. Chen, and E.H. Han: Room-temperature ductility and anisotropy of two rolled Mg–Zn–Gd alloys. Mater. Sci. Eng., A 527, 3317 (2010).

Y. Chino, X. Huang, K. Suzuki, and M. Mabuchi: Enhancement of stretch formability at room temperature by addition of Ca in Mg-Zn alloy. Mater. Trans. 51, 818 (2010).

C.L. Mendis, J.H. Bae, N.J. Kim, and K. Hono: Microstructures and tensile properties of a twin roll cast and heat-treated Mg–2.4Zn–0.1Ag–0.1Ca–0.1Zr alloy. Scr. Mater. 64, 335 (2011).

Y. Chino, T. Ueda, Y. Otomatsu, K. Sassa, X. Huang, K. Suzuki, and M. Mabuchi: Effects of Ca on tensile properties and stretch formability at room temperature in Mg-Zn and Mg-Al alloys. Mater. Trans. 52, 1477 (2011).

D.W. Kim, B.C. Suh, M.S. Shim, J.H. Bae, D.H. Kim, and N.J. Kim: Texture evolution in Mg-Zn-Ca alloy sheets. Metall. Mater. Trans. A 44, 2950 (2013).

S.J. Clark, M.D. Segall, C.J. Pickard, P.J. Hasnip, M.J. Probert, K. Refson, and M.C. Payne: First principles methods using CASTEP. Z. Kristallogr. 220, 567 (2005).

P. Hohenberg and W. Kohn: Inhomogeneous electron gas. Phys. Rev. B 136, B864 (1964).

W. Kohn and L. Sham: Self-consistent equations including exchange and correlation effects. Phys. Rev. A 140, A1133 (1965).

J.P. Perdew, J.A. Chevary, S.H. Vosko, K.A. Jackson, M.R. Pederson, D.J. Singh, and C. Fiolhais: Atoms, molecules, solids, and surfaces: Applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 46, 6671 (1992).

D. Vanderbilt: Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys. Rev. B 41, 7892 (1990).

M. Yuasa, M. Hayashi, M. Mabuchi, and Y. Chino: Improved plastic anisotropy of Mg–Zn–Ca alloys exhibiting high-stretch formability: A first-principles study. Acta Mater. 65, 207 (2014).

V. Vitek: Intrinsic stacking faults in body-centred cubic crystals. Philos. Mag. 18, 773 (1968).

J. Wang, R.G. Hoagland, J.P. Hirth, L. Capolungo, I.J. Beyerlein, and C.N. Tome: Nucleation of a \((\bar 1012)\) image twin in hexagonal close-packed crystals. Scr. Mater. 61, 903 (2009).

J. Wang, J.P. Hirth, and C.N. Tome: \((\bar 1012)\) twinning nucleation mechanisms in hexagonal-close-packed crystals. Acta Mater. 57, 5521 (2009).

M. Yuasa, M. Hayashi, M. Mabuchi, and Y. Chino: Atomic simulations of \((10\bar 12),\;(10\bar 11)\) twinning and \((10\bar 12)\) detwinning in magnesium. J. Phys.: Condens. Matter 26, 015003 (2014).

K. Hantzsche, J. Wendt, K.U. Kainer, J. Bohlen, and D. Letzig: Mg sheet: The effect of process parameters and alloy composition on texture and mechanical properties. JOM 61, 38 (2009).

M.R. Barnett: Twinning and the ductility of magnesium alloys: Part I: “Tension” twins. Mater. Sci. Eng., A 464, 1 (2007).

M. Yuasa, K. Masunaga, M. Mabuchi, and Y. Chino: Interaction mechanisms of screw dislocations with and twin boundaries in Mg. Philos. Mag. 94, 285 (2014).

K.N. Braszczynska-Malik, L. Litynska, and W. Baliga: Transmission electron microscopy investigations of AZ91 alloy deformed by equal-channel angular pressing. J. Microscopy 224, 15 (2006).

M.R. Barnett: Twinning and the ductility of magnesium alloys: Part II. “Contraction” twins. Mater. Sci. Eng., A 464, 8 (2007).

D. Ando, J. Koike, and Y. Sutou: Relationship between deformation twinning and surface step formation in AZ31 magnesium alloys. Acta Mater. 58, 4316 (2010).

P. Cizek and M.R. Barnett: Characteristics of the contraction twins formed close to the fracture surface in Mg–3Al–1Zn alloy deformed in tension. Scr. Mater. 59, 959 (2008).

K.H. Kim, B.C. Suh, J.H. Bae, M.S. Shim, S. Kimb, and N.J. Kima: Microstructure and texture evolution of Mg alloys during twin-roll casting and subsequent hot rolling. Scr. Mater. 63, 716 (2010).

Q. Jin, S.Y. Shim, and S.G. Lim: Correlation of microstructural evolution and formation basal texture in a coarse grained Mg-Al alloys during hot rolling. Scr. Mater. 55, 843 (2006).

J.C. Tan and M.J. Tan: Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet. Mater. Sci. Eng., A 339, 124 (2003).

R.S. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett: Current issues in recrystallization: A review. Mater. Sci. Eng., A 238, 219 (1997).

J. Liu, T. Liu, H. Yuan, X. Shi, and Z. Wang: Effect of cold forging and static recrystallization on microstructure and mechanical property of magnesium alloy AZ31. Mater. Trans. 51, 341 (2010).

X. Huang, K. Suzuki, Y. Chino, and M. Mabuchi: Influence of rolling temperature on static recrystallization behavior of AZ31 magnesium alloy. J. Mater. Sci. 47, 4561 (2011).

J.P. Hirth, R.C. Pond, R.G. Hoagland, X.Y. Liu, and J. Wang: Interface defects, reference spaces and the Frank–Bilby equation. Prog. Mater. Sci. 58, 749 (2013).

J. Wang and I.J. Beyerlein: Atomic structures of symmetric tilt grain boundaries in hexagonal close packed (hcp) crystals. Modell. Simul. Mater. Sci. Eng. 20, 024002 (2012).

J.A. Yasi, T. Nogaret, D.R. Trinkle, Y. Qi, L.G. Hector, Jr., and W.A. Curtin: Basal and prism dislocation cores in magnesium: Comparison of first-principles and embedded-atom-potential method predictions. Modell. Simul. Mater. Sci. Eng. 17, 055012 (2009).

J. Han, X.M. Su, Z.H. Jin, and Y.T. Zhu: Basal-plane stacking-fault energies of Mg: A first-principles study of Li- and Al-alloying effects. Scr. Mater. 64, 693 (2011).

M. Muzyk, Z. Pakiela, and K.J. Kurzydlowski: Generalized stacking fault energy in magnesium alloys: Density functional theory calculations. Scr. Mater. 66, 219 (2012).

S. Sandlobes, M. Friak, S. Zaefferer, A. Dick, S. Yi, D. Letzig, Z. Pei, L.F. Zhu, J. Neugebauer, and D. Raabe: The relation between ductility and stacking fault energies in Mg and Mg–Y alloys. Acta Mater. 60, 3011 (2012).

E.B. Tadmor and S. Hai: A Peierls criterion for the onset of deformation twinning at a crack tip. J. Mech. Phys. Solids 51, 765 (2003).

E.B. Tadmor and N. Bernstein: A first-principles measure for the twinnability of FCC metals. J. Mech. Phys. Solids. 52, 2507 (2004).

J.X. Shang and C.Y. Wang: First-principles investigation of brittle cleavage fracture of Fe grain boundaries. Phys. Rev. B 66, 184105 (2002).

S. Zhang, O.Y. Kontsevoi, A.J. Freeman, and G.B. Olson: First-principles determination of the effect of boron on aluminum grain boundary cohesion. Phys. Rev. B 84, 134104 (2011).

R.O. Kaibyshev and O.S.H. Sitdikov: On the role of twinning in dynamic recrystallization. Phys. Met. Metallogr. 89, 384 (2000).

O. Sitdikov and R. Kaibyshev: Dynamic recrystallization in pure magnesium. Mater. Trans. 42, 1928 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakano, H., Yuasa, M., Chino, Y. et al. \({\rm{\{}}10\bar 12{\rm{\}}}\) twins in the rolled Mg–Zn–Ca alloy with high formability. Journal of Materials Research 29, 3024–3031 (2014). https://doi.org/10.1557/jmr.2014.358

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.358