Abstract

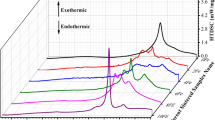

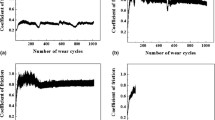

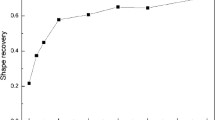

The influence of aging treatment on shape memory effect (SME) and wear resistance of Fe–20Mn–5Si–10Cr–5Ni–0.7V–0.2N (mass%) alloy was investigated. Results showed that vanadium nitride (VN) particles precipitated during aging treatment, and the amount and size of the particles increased with increasing aging time. The sample aged for 8 h exhibited the maximal shape recovery ratio of 74% (compared with that of 16% for unaged) and favorable wear resistance in both dry wear and oil-lubricant wear conditions. The fine VN particles are the key factor to improve the SME by strengthening the alloy and acting as preferential nucleation sites for martensite. However, more and larger particles due to further aging treatment appeared to have negative effects on the SME and wear resistance. After oil-lubricant friction, there existed large amounts of friction-stress-induced ε martensite in the worn surface of the sample. As a result, the wear resistance of samples in oil-lubricant wear condition was remarkably higher than that in dry wear condition.

Similar content being viewed by others

References

A. Sato, K. Soma, and T. Mori: Shape memory effect in γ⇄ϵ transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 30(6), 1171 (1982).

A. Sato and T. Mori: Development of a shape memory alloy Fe–Mn–Si. Mater. Sci. Eng., A 146(1–2), 197 (1991).

H. Inagaki: Shape memory effect of Fe-14 % Mn-6 % Si-9 % Cr-6 % Ni alloy polycrystals. Z. Metallkd. 83, 90 (1992).

Z.D. Liu, S. Kajiwara, T. Kikuchi, N. Shinya, D.F. Wang, and W.X. Liu: Mechanism of the improvement of the shape memory effect by “Training” and ausforming in Fe-Mn-Si based shape memory alloys. Mater. Trans. 41(5), 593 (2000).

T. Kırındıa, U. Sarı, and M. Dikici: The effects of pre-strain, recovery temperature, and bending deformation on shape memory effect in an Fe–Mn–Si–Cr–Ni alloy. J. Alloys Compd. 475(1–2), 145 (2009).

A. Baruj, T. Kikuchi, S. Kajiwara, and N. Shinya: Improvement of shape memory properties of NbC containing Fe–Mn–Si based shape memory alloys by simple thermomechanical treatments. Mater. Sci. Eng., A 378(1–2), 333 (2004).

Z.Z. Dong, S. Kajiwara, T. Kikuchi, and T. Sawaguchi: Effect of pre-deformation at room temperature on shape memory properties of stainless type Fe–15Mn–5Si–9Cr–5Ni–(0.5–1.5)NbC alloys. Acta Metall. 53(15), 4009 (2005).

W.B. Liu, Y.H. Wen, N. Li, and S.Z. Yang: Further improvement of shape memory effect in a pre-deformed Fe–Mn–Si–Cr–Ni–Nb–C alloy by smaller NbC precipitated through electropulsing treatment. J. Alloys Compd. 472(1–2), 591 (2009).

S. Farjami, K. Hiraga, and H. Kubo: Crystallography and elastic energy analysis of VN precipitates in Fe–Mn–Si–Cr shape memory alloys. Acta Mater. 53(2), 419 (2005).

H. Kubo, K. Nakamura, S. Farjami, and T. Maruyama: Characterization of Fe–Mn–Si–Cr shape memory alloys containing VN precipitates. Mater. Sci. Eng., A 378(1–2), 343 (2004).

Z.Z. Dong, U.E. Klotz, and C. Leinenbach: A novel Fe-Mn-Si shape memory alloy with improved shape recovery properties by VC precipitation. Adv. Eng. Mater. 11(1–2), 40 (2009).

Y.H. Wen, L.R. Xiong, N. Li, and W. Zhang: Remarkable improvement of shape memory effect in an Fe–Mn–Si–Cr–Ni–C alloy through controlling precipitation direction of Cr23C6. Mater. Sci. Eng., A 474(1–2), 60 (2008).

H.B. Peng, Y.H. Wen, B.B. Ye, and N. Li: Influence of ageing after pre-deformation on shape memory effect in a FeMnSiCrNiC alloy with 13 wt.% Cr content. Mater. Sci. Eng., A 504(1–2), 36 (2009).

D.X. Bu, H.B. Peng, Y.H. Wen, and N. Li: Influence of ageing on wear resistance of an Fe–Mn–Si–Cr–Ni–Ti–C shape memory alloy. Mater. Des. 32(5), 2969 (2011).

C.X. Lin, G.X. Wang, Y.D. Wu, J.G. Wang, and J.J. Zhang: Analysis of wear resistance and its mechanism in an Fe–Mn–Si–Cr–Ni shape memory alloy. Mater. Sci. Eng., A 438, 804 (2006).

S. Kajiwara: Characteristic features of shape memory effect and related transformation behavior in Fe-based alloys. Mater. Sci. Eng., A 273, 67 (1999).

J.J. Ye, Z.W. Lai, Y.H. Wen, and N. Li: Wear characteristics of a new type austenitic stainless steel. J. Mater. Sci. 45(3), 701 (2010).

Z.F. Ni, Y.S. Sun, F. Xue, J. Zhou, and J. Bai: Evaluation of electroslag remelting in TiC particle reinforced 304 stainless steel. Mater. Sci. Eng., A 528(18), 5664 (2011).

K. Yang, S.F. Yu, Y.B. Li, and C.L. Li: Effect of carbonitride precipitates on the abrasive wear behaviour of hardfacing alloy. Appl. Surf. Sci. 254(16), 5023 (2008).

ACKNOWLEDGMENTS

The authors are grateful to the Natural Science Foundation of Tianjin City (No. 13JCZDJC31900), the China National Funds for Distinguished Young Scientists (No. 51325401), the International Thermonuclear Experimental Reactor (ITER) Program Special Project (No. 2014GB125006), and the Major State Basic Research Development Program (973 Program No. 2014CB046805) for grant and financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Y., Dong, Z., Yu, L. et al. Effects of aging on shape memory and wear resistance of a Fe–Mn–Si-based alloy. Journal of Materials Research 29, 2809–2816 (2014). https://doi.org/10.1557/jmr.2014.344

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.344