Abstract

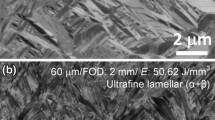

Ti–6Al–4V parts made by the additive manufacturing (AM) technique selective laser melting (SLM) generally show poor ductility due to their fine martensitic microstructure. This study was designed to assess whether a more suitable microstructure can be obtained when long laser/material interaction times are used. As-fabricated components with an α + β microstructure were produced and characterized with various microscopy techniques. The microstructural evolution was discussed in relation to the build platform temperature, the cyclic reheating, and the thermal stresses that developed during the process. The hardness of the samples was also evaluated and discussed. The hardness varied in relation to the different microstructure morphologies observed in the samples and different partitioning of the alloying elements. This study indicates a methodology through SLM to obtain Ti–6Al–4V with an as-deposited α + β microstructure which is more desirable than that the typical fully martensitic microstructure typically obtained after SLM.

Similar content being viewed by others

References

M. Baumers, C. Tuck, R. Wildman, I. Ashcroft, and R. Hague: Energy inputs to additive manufacturing: Does capacity utilization matter?. Proceedings of the Solid Freeform Fabrication Symposium, 2011. (EOS, 1000, 270, 2011); pp. 30–40.

C. Qiu, N. Adkins, and M.M. Attallah: Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng., A 578, 230 (2013).

L. Facchini, E. Magalini, P. Robotti, A. Molinari, S. Höges, and K. Wissenbach: Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyping J. 16, 450 (2010).

T. Vilaro, C. Colin, and J.D. Bartout: As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 42, 3190 (2011).

E. Chlebus, B. Kuźnicka, T. Kurzynowski, and B. Dybała: Microstructure and mechanical behaviour of Ti―6Al―7Nb alloy produced by selective laser melting. Mater. Charact. 62, 488 (2011).

D. Banerjee and J.C. Williams: Perspectives on titanium science and technology. Acta Mater. 61(3), 844 (2013).

G. Lütjering: Influence of processing on microstructure and mechanical properties of α+ β titanium alloys. Mater. Sci. Eng., A 243(1), 32 (1998).

B. Vrancken, L. Thijs, J.P. Kruth, and J.V. Humbeeck: Heat treatment of Ti-6Al-4V produced by selective laser melting: Microstructure and mechanical properties. J. Alloys Compd. 541, 177 (2012).

L. Thijs, F. Verhaeghe, T. Craeghs, J.V. Humbeeck, and J.P. Kruth: A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 58, 3303 (2010).

T. Sercombe, N. Jones, R. Day, and A. Kop: Heat treatment of Ti-6Al-7Nb components produced by selective laser melting. Rapid Prototyping J. 14, 300 (2008).

M. Simonelli, Y.Y. Tse, and C. Tuck: On the texture formation of selective laser melted Ti-6Al-4V. Metall. Mater. Trans. A 45(6), 2863 (2014).

E. Yasa and J.P. Kruth: Microstructural investigation of selective laser melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 19, 389 (2011).

S.S. Al-Bermani, M.L. Blackmore, W. Zhang, and I. Todd: The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A 41, 3422 (2010).

I. Gibson, D.W. Rosen, and B. Stucker: Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing (Springer, New York, NY, 2010), pp. 103–142.

A. Crespo and R. Vilar: Finite element analysis of the rapid manufacturing of Ti–6Al–4V parts by laser powder deposition. Scr. Mater. 63, 140 (2010).

M. Shiomi, K. Osakada, K. Nakamura, T. Yamashita, and F. Abe: Residual stress within metallic model made by selective laser melting process. CIRP Ann.-Manuf. Technol. 53, 195 (2004).

P. Mercelis and J.P. Kruth: Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyping J. 12, 254 (2006).

P.A. Kobryn and S.L. Semiatin: The laser additive manufacture of Ti-6Al-4V. JOM 53, 40 (2001).

P.A. Kobryn and S.L. Semiatin: Microstructure and texture evolution during solidification processing of Ti–6Al–4V. J. Mater. Process. Technol. 135, 330 (2003).

L.E. Murr, S.A. Quinones, S.M. Gaytan, M.I. Lopez, A. Rodela, E.Y. Martinez, D.H. Hernandez, E. Martinez, F. Medina, and R.B. Wicker: Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2, 20 (2009).

T. Ahmed and H.J. Rack: Phase transformations during cooling in α+β titanium alloys. Mater. Sci. Eng., A 243, 206 (1998).

J.I. Qazi, J. Rahim, F.H. Fores, O.N. Senkov, and A. Genc: Phase transformations in Ti-6Al-4V-xH alloys. Metall. Mater. Trans. A 32, 2453 (2001).

S.M. Kelly and S.L. Kampe: Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part I. Microstructural characterization. Metall. Mater. Trans. A, 35, 1861 (2004).

B. Baufeld, E. Brandl, and O.V. Biest: Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti–6Al–4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 211, 1146 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Simonelli, M., Tse, Y.Y. & Tuck, C. The formation of α + β microstructure in as-fabricated selective laser melting of Ti–6Al–4V. Journal of Materials Research 29, 2028–2035 (2014). https://doi.org/10.1557/jmr.2014.166

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.166