Abstract

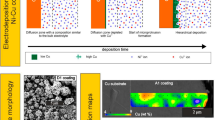

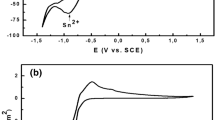

A Cu–Ni sectioned cathode made up of two hemicycles of each of the metals was used for reactive co-sputtering of a thin film combinatorial library of Cu–Ni oxides covering a total compositional spread of 63 at.%. The thickness profiling of the library showed a nonuniform film thickness with a maximum region shifted toward the Cu side of the cathode. The presence of CuO, Cu2O, NiO, and metallic Cu–Ni alloys was identified during the scanning x-ray diffraction investigations along the compositional spread. A distinct structural zone was defined between Cu–14 at.% Ni and Cu–19 at.% Ni, where the scanning electron microscopy investigations showed a higher surface porosity combined with smaller grain sizes. This zone corresponds to the maximum film thickness region and correlates well with the position of the maximum work function of the Cu–Ni oxide films as mapped using a scanning Kelvin probe. During local corrosion studies focused on Cu dissolution, an improved corrosion resistance was identified in the Ni rich side of the compositional spread.

Similar content being viewed by others

REFERENCES

D. Monell: Manufacture of Nickel-Copper Alloys. U.S. Patent No. 8 112 39, 1911.

M.A. Laughton and D.F. Warne: Electrical Engineer’s Reference Book, 6th ed. (Elsevier Science, Oxford, England, 2003), pp. 10–43.

J.W. Schultze and A.W. Hassel: Passivity of metals, alloys, and semiconductors. In Encyclopedia of electrochemistry, Vol. 4. Corrosion and Oxide Films; A.J. Bard, M. Stratmann, and G.S. Frankel (Wiley-VCH, Weinheim, Germany, 2007); pp. 216-280 & pp. 188-189.

K. Hashimoto, M. Yamasaki, S. Meguro, T. Sasaki, H. Katagiri, K. Izumiya, N. Kumagai, H. Habazaki, E. Akiyama, and K. Asami: Materials for global carbon dioxide recycling. Corros. Sci. 44, 371 (2002).

M. Miyauchi, A. Nakajima, T. Watanabe, and K. Hashimoto: Photocatalysis and photoinduced hydrophilicity of various metal oxide thin films. Chem. Mater. 14, 2812 (2002).

I. Hotovy, J. Huran, J. Janik, and A.B. Kobzev: Deposition and properties of nickel oxide films produced by DC reactive magnetron sputtering. Vacuum 51, 157 (1998).

I. Hotovy, D. Buc, S. Hascik, and O. Nennewitz: Characterization of NiO thin films deposited by reactive sputtering. Vacuum 50, 41 (1998).

H-L. Chen and Y-S. Yang: Effect of crystallographic orientations on electrical properties of sputter-deposited nickel oxide thin films. Thin Solid Films 516, 5590 (2008).

J-L. Yang, Y-S. Lai, and J.S. Chen: Effect of heat treatment on the properties of non-stoichiometric p-type nickel oxide films deposited by reactive sputtering. Thin Solid Films 488, 242 (2005).

A. Karpinski, A. Ferrec, M. Richard-Plouet, L. Cattin, M.A. Djouadi, L. Brohan, and P-Y. Jouan: Deposition of nickel oxide by direct current reactive sputtering effect of oxygen partial pressure. Thin Solid Films 520, 3609 (2012).

L. Courtade, C. Turquat, C. Muller, J.G. Lisoni, L. Goux, D.J. Wouters, D. Goguenheim, P. Roussel, and L. Ortega: Oxidation kinetics of Ni metallic films- formation of NiO-based resistive switching structures. Thin Solid Films 516, 4083 (2008).

S. Otsuka, S. Furuya, R. Takeda, T. Shimizu, S. Shingubara, T. Watanabe, Y. Takano, and K. Takase: Resistive switching characteristics of NiO/Ni nanostructure. Microelectron. Eng. 98, 367 (2012).

C.B. Lee, B.S. Kang, A. Benayad, M.J. Lee, S-E. Ahn, K.H. Kim, G. Stefanovic, Y. Park, and I.K. Yoo: Effects of metal electrodes on the resistive memory switching property of NiO thin films. Appl. Phys. Lett. 93, 042115 (2008).

X. Song, L. Gao, and S. Mathur: Synthesis, characterization, and gas sensing properties of porous nickel oxide nanotubes. J. Phys. Chem. C 115, 21730 (2011).

N. Nancheva, P. Docheva, and M. Misheva: Defects in Cu and Cu–O films produced by reactive magnetron sputtering. Mater. Lett. 39, 81 (1999).

R. Chandra, P. Taneja, and P. Ayyub: Optical properties of transparent nanocrystalline Cu2O thin films synthesized by high pressure gas sputtering. Nanostruct. Mater. 11, 505 (1999).

A. Sivasankar Reddy, S. Uthanna, and P. Sreedhara Reddy: Properties of dc magnetron sputtered Cu2O films prepared at different sputtering pressures. Appl. Surf. Sci. 253, 5287 (2007).

A. Sivasankar Reddy, G. Venkata Rao, S. Uthanna, and P. Sreedhara Reddy: Structural and optical studies on dc reactive magnetron sputtered Cu2O films. Mater. Lett. 60, 1617 (2006).

H. Zhu, J. Zhang, C. Li, F. Pan, T. Wang, and B. Huang: Cu2O thin films deposited by reactive direct current magnetron sputtering. Thin Solid Films 517, 5700 (2009).

M. Hara, T. Kondo, M. Komoda, S. Ikeda, K. Shinohara, A. Tanaka, J.N. Kondoa, and K. Domen: Cu2O as a photocatalyst for overall water splitting under visible light irradiation. Chem. Commun. (3), 357 (1998). doi: 10.1039/A707440I.

K. Akimoto, S. Ishizuka, M Yanagita, Y Nawa, G.K. Paul, and T. Sakurai: Thin film deposition of Cu2O and application for solar cells. Sol. Energy 80, 715 (2006).

W-Y. Yang and S-W. Rhee: Effect of electrode material on the resistance switching of Cu2O films. Appl. Phys. Lett. 91, 232907 (2007).

V. Miteva, D. Karpuzov, P. Ivanov, and St. Angelova: Stoichiometry effects at Cu-Ni alloy surfaces during 5 keV Ar ion sputtering at room temperature. Nucl. Instrum. Methods Phys. Res., Sect. B 85, 340 (1994).

W.M. Posadowski: Self-sustained magnetron co-sputtering of Cu and Ni. Thin Solid Films 459, 258 (2004).

M. Yang, Z. Shi, J. Feng, H. Pu, G. Li, J. Zhou, and Q. Zhang: Copper doped nickel oxide transparent p-type conductive thin films deposited by pulsed plasma deposition. Thin Solid Films 519, 3021 (2011).

N. Kikuchi, K. Tonooka, and E. Kusano: Mechanisms of carrier generation and transport in Ni-doped Cu2O. Vacuum 80, 756 (2006).

W. Burgstaller, A.I. Mardare, and A.W. Hassel: Copper-zinc thin films reactively co-sputtered from a two-component sectioned cathode. Phys. Status Solidi A 210, 994 (2013).

M. Voith, G. Luckeneder, and A.W. Hassel: In situ identification and quantification in a flow cell with AAS downstream analytics. J. Sol. State Electrochem. 16, 3473 (2012).

K. Wasa and S. Hayakawa: Handbook of Sputter Deposition Technology (Noyes Publications, Westwood, NJ, 2003), p. 57.

M. Ohring: Materials Science of Thin Films, 2nd ed. (Academic Press, Waltham, MA, 2001), p. 176.

J.A. Thornton: The microstructure of sputter-deposited coatings. J. Vac. Sci. Technol., A 4, 3056 (1986).

A.I. Mardare, A.P. Yadav, A.D. Wieck, M. Stratmann, and A.W. Hassel: Combinatorial electrochemistry on Al-Fe alloys. Sci. Technol. Adv. Mater. 9, 035009 (2008).

A.I. Mardare, A. Ludwig, A. Savan, A.D. Wieck, and A.W. Hassel: High-throughput study of the anodic oxidation of Hf-Ti thin films. Electrochim. Acta 54, 5171 (2009).

A.I. Mardare, A. Savan, A. Ludwig, A.D. Wieck, and A.W. Hassel: High-throughput synthesis and characterization of anodic oxides on Nb-Ti alloys. Electrochim. Acta 54, 5973 (2009).

A.I. Mardare, A. Ludwig, A. Savan, A.D. Wieck, and A.W. Hassel: Combinatorial investigation of Hf-Ta thin films and their anodic oxides. Electrochim. Acta 55, 7884 (2010).

R.T. Atanasoski, S-M. Huang, O. Albani, and R.A. Orani: A dry redox couple employed as the reference material in work function and corrosion potential measurements by the Kelvin technique. Corros. Sci. 36, 1513 (1994).

W.N. Hansen and G.J. Hansen: Standard reference surfaces for work function measurements in air. Surf. Sci. 481, 172 (2001).

ACKNOWLEDGMENTS

The authors gratefully acknowledge assistance in XPS measurements by Jiri Duchoslav (ZONA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Burgstaller, W., Hafner, M., Voith, M. et al. Copper–nickel oxide thin film library reactively co-sputtered from a metallic sectioned cathode. Journal of Materials Research 29, 148–157 (2014). https://doi.org/10.1557/jmr.2013.336

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.336