Abstract

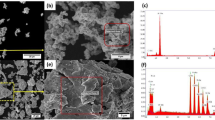

In this paper, the effect of the addition of tungsten carbide on the behavior of Fe–WC system during the mechanical alloying (MA) process has been investigated. For this purpose, raw materials containing industrial ferrotungsten and carbon black with a bit of tungsten carbide powder were milled in a high energy ball mill, and sampling was done at different times. An XRD instrument was used for estimating the probable transformation of phases and properties in the milled sample. Microstructures of specimens were studied using electron microscopy. Results showed that MA even at high milling time could not transform raw materials to other materials in a system containing ferrotungsten and carbon black. In samples with primary tungsten carbide, this was synthesized gradually at a milling time of more than 75 h, and finally, the Fe–WC composite was produced as the final product. Crystalline sizes of the synthesized carbide were in nanometer order that was confirmed by transmission electron microscopy images.

Similar content being viewed by others

References

A. Mortensen and J. Llorca: Metal matrix composites. Annu. Rev. Mater. Res. 40, 243 (2010).

K. Dash, B.C. Ray, and D. Chaira: Synthesis and characterization of copper–alumina metal matrix composite by conventional and spark plasma sintering. J. Alloys Compd. 516, 78 (2012).

G. Fan and Y. Sun: Effect of pressure on the solidification behavior and mechanical properties of SiCp/Al-Mg composites. J. Wuhan Uni. Technol. - Mater. Sci. Ed. 28(2), 274 (2013).

R. Gautam, S. Ray, S.C. Sharma, S. Jain, and R. Tyagi: Dry sliding wear behavior of hot forged and annealed Cu–Cr–graphite in-situ composites. Wear 271(5), 658 (2011).

A. Miserez, R. Müller, A. Rossoll, L. Weber, and A. Mortensen: Particle reinforced metals of high ceramic content. Mater. Sci. Eng., A 387, 822 (2004).

A. Evans, C. San Marchi, and A. Mortensen: Metal Matrix Composites in Industry: An Introduction and a Survey (Springer, New York, NY, 2003).

K.S. Tun and M. Gupta: Improving mechanical properties of magnesium using nano-yttria reinforcement and microwave assisted powder metallurgy method. Compos. Sci. Technol. 67(13), 2657 (2007).

N. Chawla and K. Chawla: Metal-matrix composites in ground transportation. JOM 58(11), 67 (2006).

W. Pedersen and M. Ramulu: Facing SiCp/Mg metal matrix composites with carbide tools. J. Mater. Process. Technol. 172(3), 417 (2006).

D. Miracle: Metal matrix composites–from science to technological significance. Compos. Sci. Technol. 65(15), 2526 (2005).

G. Constantinides, K. Ravi Chandran, F-J. Ulm, and K. Van Vliet: Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater. Sci. Eng., A 430(1), 189 (2006).

T.H. Nam, G. Requena, and P. Degischer: Thermal expansion behaviour of aluminum matrix composites with densely packed SiC particles. Composites Part A 39(5), 856 (2008).

T.G. Ryu, H.Y. Sohn, K.S. Hwang, and Z.Z. Fang: Tungsten carbide nanopowder by plasma-assisted chemical vapor synthesis from WCl6-CH4-H2 mixtures. J. Mater. Sci. 43(15), 5185 (2008).

R. Lu, L. Minarro, Y.Y. Su, and R.M. Shemenski: Failure mechanism of cemented tungsten carbide dies in wet drawing process of steel cord filament. Int. J. Refract. Met. Hard Mater. 26(6), 589 (2008).

P-H. Gao, Y-G. Li, C-J. Li, G-J. Yang, and C-X. Li: Influence of powder porous structure on the deposition behavior of cold-sprayed WC-12Co coatings. J. Therm. Spray Technol. 17(5–6), 742 (2008).

Y.V. Milman, S. Luyckx, V. Goncharuck, and J. Northrop: Results from bending tests on submicron and micron WC–Co grades at elevated temperatures. Int. J. Refract. Met. Hard Mater. 20(1), 71 (2002).

P-H. Gao, C-J. Li, G-J. Yang, Y-G. Li, and C-X. Li: Influence of substrate hardness transition on built-up of nanostructured WC–12Co by cold spraying. Appl. Surf. Sci. 256(7), 2263 (2010).

J. Zhang, G. Zhang, S. Zhao, and X. Song: Binder-free WC bulk synthesized by spark plasma sintering. J Alloys Compd. 479(1), 427 (2009).

E. Marui, H. Endo, and A. Ohira: Wear test of cemented tungsten carbide at high atmospheric temperature (400 °C). Tribol. Lett. 8(2–3), 139 (2000).

Z. Lin, L. Wang, J. Zhang, H-K. Mao, and Y. Zhao: Nanocrystalline tungsten carbide: As incompressible as diamond. Appl. Phys. Lett. 95(21), 211906 (2009).

D-H. Xiao, Y-H. He, W-H. Luo, and M. Song: Effect of VC and NbC additions on microstructure and properties of ultrafine WC-10Co cemented carbides. Trans. Nonferrous Met. Soc. China 19(6), 1520 (2009).

T. Klünsner, S. Marsoner, R. Ebner, R. Pippan, J. Glätzle, and A. Püschel: Effect of microstructure on fatigue properties of WC-Co hard metals. Procedia Eng. 2(1), 2001 (2010).

S. Zhou and X. Dai: Microstructure evolution of Fe-based WC composite coating prepared by laser induction hybrid rapid cladding. Appl. Surf. Sci. 256(24), 7395 (2010).

C.M. Fernandes, A.M.R. Senos, and M.T. Vieira: Sintering of tungsten carbide particles sputter-deposited with stainless steel. Int. J. Refract. Met. Hard Mater. 21(3–4), 147 (2003).

X.Q. You, C.J. Zhang, X.F. Song, M.P. Huang, and J.G. Ma: Microstructure evolution of WC/steel composite by laser surface re-melting. Appl. Surf. Sci. 253(9), 4409 (2007).

Z.Z. Fang, X. Wang, T. Ryu, K.S. Hwang, and H. Sohn: Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide–a review. Int. J. Refract. Met. Hard Mater. 27(2), 288 (2009).

Powder Metallurgy Technologies and Applications, 10th ed. (ASM International, 1990).

T. Ryu, M. Olivas-Martinez, H.Y. Sohn, Z. Fang, and T.A. Ring: Computational fluid dynamics simulation of chemical vapor synthesis of WC nanopowder from tungsten hexachloride. Chem. Eng. Sci. 65(5), 1773 (2010).

P.W. Lee, Y. Trudel, R.M. German, B.L. Ferguson, W.B. Eisen, K. Mover, D. Madan, H. Sanderow, S.R. Lampman, and G.M. Davidson: Powder metal technologies and applications, 10th ed. (ASM International, Materials Park, OH, 1990).

S.A. Hewitt and K.A. Kibble: Effects of ball milling time on the synthesis and consolidation of nanostructured WC–Co composites. Int. J. Refract. Met. Hard Mater. 27(6), 937 (2009).

M. Razavi, M.R. Rahimipour, and R. Yazdani-Rad: A novel technique for production of nano-crystalline mono tungsten carbide single phase via mechanical alloying. J. Alloys Compd. 509(23), 6683 (2011).

M. Razavi, M. Rahimipour, and R. Yazdani-Rad: Synthesis of Fe-WC nanocomposite from industrial ferrotungsten via mechanical alloying method. Adv. Appl. Ceram. 110(6), 367 (2011).

A. Standard: Method for Determination of Tap Density of Metallic Powders and Compounds (ASTM International, West Conshohocken, PA, 2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Razavi, M. Effect of addition of primary tungsten carbide on the properties of ferrotungsten and carbon black powders during mechanical alloying process. Journal of Materials Research 28, 2996–3002 (2013). https://doi.org/10.1557/jmr.2013.269

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.269