Abstract

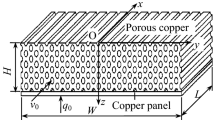

Heat transfer coefficients of porous copper samples with single- and double-layer structures, fabricated by the lost carbonate sintering process, were measured under forced convection conditions using water as the coolant. Compared with the empty channel, introducing a porous copper sample enhanced the heat transfer coefficient 5–8 times. The porous copper samples with double layers of porosities of 60% and 80% often had lower heat transfer coefficients than their single layer counterparts with the same overall porosities because the coolant flowed predominantly through the high-porosity layer. For the same double-layer structure, the order of the double layer had a large effect on the heat transfer coefficient. Placing the high-porosity layer next to the heat source was more efficient than the other way around. The predictions of a segment model developed for the heat transfer coefficient of multilayer structures agreed well with the experimental results.

Similar content being viewed by others

References

A.A. Sertkaya, K. Altinisik, and K. Dincer: Experimental investigation of thermal performance of aluminum finned heat exchangers and open-cell aluminum foam heat exchangers. Exp. Therm. Fluid Sci. 36, 86 (2012).

W. Lu, C.Y. Zhao, and S.A. Tassou: Thermal analysis on metal-foam filled heat exchangers. Part I: Metal-foam filled pipes. Int. J. Heat Mass Transfer 49, 2751 (2006).

C.Y. Zhao, W. Lu, and S.A. Tassou: Thermal analysis on metal-foam filled heat exchangers. Part II: Tube heat exchangers. Int. J. Heat Mass Transfer 49, 2762 (2006).

P.X. Jiang, M. Li, T.J. Lu, L. Yu, and Z.P. Ren: Experimental research on convection heat transfer in sintered porous plate channels. Int. J. Heat Mass Transfer 47, 2085 (2004).

C.Y. Zhao, T. Kim, T.J. Lu, and H.P. Hodson: Thermal transport in high porosity cellular metal foams. J. Thermophys. Heat Transfer 18, 309 (2004).

H.Y. Zhang, D. Pinjala, T.N. Wong, and Y.K. Joshi: Development of liquid cooling techniques for flip chip ball grid array packages with high heat flux dissipations. IEEE Trans. Compon. Packag. Technol. 28, 127 (2005).

K. Boomsma, D. Poulikakos, and F. Zwick: Metal foams as compact high performance heat exchangers. Mech. Mater. 35, 1161 (2003).

Y.Y. Zhao, T. Fung, L.P. Zhang, and F.L. Zhang: Lost carbonate sintering process for manufacturing metal foams. Scr. Mater. 52, 295 (2005).

D.J. Thewsey and Y.Y. Zhao: Thermal conductivity of porous copper manufactured by the lost carbonate sintering process. Phys. Status Solidi A 205, 1126 (2008).

L.P. Zhang and Y.Y. Zhao: Fabrication of high melting-point porous metals by lost carbonate sintering process via decomposition route. J. Eng. Manuf. 222, 267 (2008).

M.M. Mahmoud: Manufacturing, testing, and modeling of copper foams. Global J. Pure Appl. Sci. 0212, 5 (2012).

A.M. Parvanian and M. Panjepour: Mechanical behavior improvement of open-pore copper foams synthesized through space holder technique. Mater. Des. 49, 834 (2013).

L. Zhang, D. Mullen, K. Lynn, and Y. Zhao: Heat transfer performance of porous copper fabricated by the lost carbonate sintering process, in Architectured Multifunctional Materials, edited by Y. Brechet, J.D. Embury, and P.R. Onck (Mater. Res. Soc. Symp. Proc. 1188, Warrendale, PA, 2009).

R.J. Moffat: Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1, 3 (1988).

A. Dybbs and R.V. Edwards: A new look at porous media fluid mechanics–Darcy to turbulent, in Fundamentals of Transport in Phenomena Porous Media, Vol. 82, J. Bear and M.Y. Corapciolgu eds.; NATO ASI Ser. Martinus Nijhoff Publishers: Dordrecht, Netherland, 1984, p. 199.

C.K. Ho and S.W. Webb: Gas Transport in Porous Media (Springer, Albuquerque, NM, 2006).

F.P. Incropera, D.P. Dewitt, T.L. Bergman, and A.S. Lavine: Principles of Heat and Mass Transfer (John Wiley & Sons, Hoboken, NJ, 2013), p. 154.

Acknowledgments

This work was supported by the Technology Strategy Board, UK (TP/8/MAT/6/I/Q1568F). The authors would like to thank Ecka Granules Metal Powder Ltd for supplying the copper powder. Z. Xiao would like to thank the University of Liverpool and the Chinese Scholarship Council for a studentship.

Author information

Authors and Affiliations

Corresponding author

Nomenclature

- A

-

cross-sectional area of sample

- d

-

distance between Tt and Tb

- D

-

Average pore size

- f

-

thickness fraction

- h

-

heat transfer coefficient

- J

-

total heat flux

- J cond

-

conductive heat flux

- J conv

-

convective heat flux

- k

-

thermal conductivity of porous copper

- k Cu

-

thermal conductivity of copper

- K

-

permeability

- L

-

length of sample

- m

-

constant

- p

-

partition factor

- ΔP

-

pressure drop

- Q

-

fluid flux

- R

-

correlation factor

- ReD

-

Reynolds number based on average pore size

- s

-

scale factor

- t

-

thickness of sample

- T

-

temperature of porous copper

- T b

-

temperature of heating block, bottom

- T t

-

temperature of heating plate, top

- T f

-

temperature of coolant

- T in

-

temperature of inlet water

- T out

-

temperature of outlet water

- v

-

Darcian velocity

- w

-

weighting factor

- x

-

distance from heating plate

Rights and permissions

About this article

Cite this article

Xiao, Z., Zhao, Y. Heat transfer coefficient of porous copper with homogeneous and hybrid structures in active cooling. Journal of Materials Research 28, 2545–2553 (2013). https://doi.org/10.1557/jmr.2013.190

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.190