Abstract

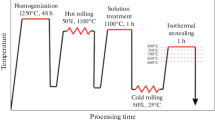

Pearlitic transformation in an ultrafine-grained (UFG) hypereutectoid steel was investigated. The steel was a plain carbon steel containing 1.0 wt% C and very few other elements. The UFG samples were prepared by thermomechanical treatment, and an average grain size of approximately 1 μm was achieved. The pearlitic transformation was conducted by heating the UFG samples at 1023 K for different times and then cooling in air. A new pearlitic transformation phenomenon was observed: traditional lamellar pearlite can be observed only when the grain size increases to a dimension larger than approximately 4 μm, which is a critical value. When grain size is smaller than this value, the pearlitic transformation occurs in the form of divorced eutectoid, and the microstructure is the ferrite matrix with granular cementite. This research indicates that grain size has a great influence on pearlitic transformation by shortening the diffusion distance and increasing the diffusion rate of carbon atoms in the UFG steel.

Similar content being viewed by others

References

Y. Ivanisenko, I. MacLaren, X. Sauvage, R.Z. Valiev, and H.J. Fecht: Shear-induced α → γ transformation in nanoscale Fe–C composite. Acta Mater. 54(6), 1659 (2006).

H. Kitahara, N. Tsuji, and Y. Minamino: Martensite transformation from ultrafine grained austenite in Fe–28.5 at.% Ni. Mater. Sci. Eng., A. 438–440, 233 (2006).

T. Waitz and H.P. Karnthaler: Martensitic transformation of NiTi nanocrystals embedded in an amorphous matrix. Acta Mater. 52(19), 5461 (2004).

Y.B. Wang, Y.H. Zhao, Q. Lian, X.Z. Liao, R.Z. Valiev, S.P. Ringer, Y.T. Zhu, and E.J. Lavernia: Grain size and reversible beta-to-omega phase transformation in a Ti alloy. Scr. Mater. 63(6), 613 (2010).

S. Ohsaki, K. Hono, H. Hidaka, and S. Takaki: Characterization of nanocrystalline ferrite produced by mechanical milling of pearlitic steel. Scr. Mater. 52(4), 271 (2005).

Y.N. Liu, T. He, G.J. Peng, and F.L. Lian: Pearlitic transformations in an ultrafine-grained hypereutectoid steel. Metall. Mater. Trans. A. 42(8), 2144 (2011).

S. Rajasekhara and P.J. Ferreira: Martensite → austenite phase transformation kinetics in an ultrafine-grained metastable austenitic stainless steel. Acta Mater. 59(2), 738 (2011).

A. Böhner, T. Niendorf, D. Amberger, H.W. Höppel, M. Göken, and H.J. Maier: Martensitic transformation in ultrafine-grained stainless steel AISI 304L under monotonic and cyclic loading. Metals 2(1), 56 (2012).

T. Waitz, V. Kazykhanov, and H.P. Karnthaler: Martensitic phase transformations in nanocrystalline NiTi studied by TEM. Acta Mater. 52(1), 137 (2004).

R. Song, D. Ponge, D. Raabe, and R. Kaspar: Microstructure and crystallographic texture of an ultrafine grained C–Mn steel and their evolution during warm deformation and annealing. Acta Mater. 53(3), 845 (2005).

R. Song, D. Ponge, D. Raabe, J.G. Speer, and D.K. Matlock: Overview of processing, microstructure and mechanical properties of ultrafine grained bcc steels. Mater. Sci. Eng., A. 441(1–2), 1 (2006).

A. Najafi-Zadeh, J. Jonas, and S. Yue: Grain refinement by dynamic recrystallization during the simulated warm-rolling of interstitial free steels. Metall. Mater. Trans. A. 23(9), 2607 (1992).

S.V.S.N. Murty, S. Torizuka, K. Nagai, T. Kitai, and Y. Kogo: Dynamic recrystallization of ferrite during warm deformation of ultrafine grained ultra-low carbon steel. Scr. Mater. 53(6), 763 (2005).

H. Dong and X.J. Sun: Deformation induced ferrite transformation in low carbon steels. Curr. Opin. Solid State Mater. Sci. 9(6), 269 (2005).

R. Bengochea, B. López, and I. Gutierrez: Microstructural evolution during the austenite-to-ferrite transformation from deformed austenite. Metall. Mater. Trans. A. 29(2), 417 (1998).

T. Ungár, I. Alexandrov, and M. Zehetbauer: Ultrafine-grained microstructures evolving during severe plastic deformation. JOM. 52(4), 34 (2000).

L.X. Du, S.J. Yao, X.H. Liu, and G.D. Wang: Growth behavior of ultrafine austenite grains in microalloyed steel. Acta Metall. Sinica 22(1), 7 (2009).

Q.Y. Liu, S.H. Deng, X.J. Sun, H. Dong, and Y.Q. Weng: Effect of dissolved and precipitated niobium in microalloyed steel on deformation induced ferrite transformation (DIFT). J. Iron. Steel Res. Int. 16(4), 67 (2009).

E. Ahmad, M. Sarwar, T. Manzoor, and N. Hussain: Ultrafine grain refinement in a low alloy steel. J. Mater. Eng. Perform. 15(3), 345 (2006).

J.M. Aquino, C.A. Della Rovere, and S.E. Kuri: Intergranular corrosion susceptibility in supermartensitic stainless steel weldments. Corros. Sci. 51(10), 2316 (2009).

S. Jain, N.D. Budiansky, J.L. Hudson, and J.R. Scully: Surface spreading of intergranular corrosion on stainless steels. Corros. Sci. 52(3), 873 (2010).

J. Gong, Y.M. Jiang, B. Deng, J.L. Xu, J.P. Hu, and J. Li: Evaluation of intergranular corrosion susceptibility of UNS S31803 duplex stainless steel with an optimized double loop electrochemical potentiokinetic reactivation method. Electrochim. Acta 55(18), 5077 (2010).

H. Tan, Y.M. Jiang, B. Deng, W.J. Gao, and J. Li: Evaluation of aged Incoloy 800 alloy sensitization to intergranular corrosion by means of double loop electrochemical methods and image analysis. Nucl. Eng. Des. 241(5), 1421 (2011).

J. Verhoeven and E. Gibson: The divorced eutectoid transformation in steel. Metall. Mater. Trans. A. 29(4), 1181 (1998).

T. Oyama, O.D. Sherby, J. Wadsworth, and B. Walser: Application of the divorced eutectoid transformation to the development of fine-grained, spheroidized structures in ultrahigh carbon steels. Scr. Metall. Mater. 18(8), 799 (1984).

C. Syn, D. Lesuer, and O. Sherby: Influence of microstructure on tensile properties of spheroidized ultrahigh-carbon (1.8 Pct C) steel. Metall. Mater. Trans. A. 25(7), 1481 (1994).

E. Taleff, C. Syn, D. Lesuer, and O. Sherby: Pearlite in ultrahigh carbon steels: Heat treatments and mechanical properties. Metall. Mater. Trans. A. 27(1), 111 (1996).

P.W. Payson, W.L. Hodapp, and J. Leeder: The spheroidizing of steel by isothermal transformation. Trans. Am. Soc. Metals 28, 306 (1940).

J. Verhoeven: The role of the divorced eutectoid transformation in the spheroidization of 52100 steel. Metall. Mater. Trans. A. 31(10), 2431 (2000).

W.P. Tong, N.R. Tao, Z.B. Wang, J. Lu, and K. Lu: Nitriding iron at lower temperatures. Science 299(5607), 686 (2003).

B. Bokstein and I. Razumovskii: Grain boundary diffusion and segregation in interstitial solid solutions based on bcc transition metals: Carbon in niobium. Interface Sci. 11(1), 41 (2003).

F. Christien, R. Le Gall, and G. Saindrenan: Phosphorus grain boundary segregation in steel 17-4PH. Scr. Mater. 48(1), 11 (2003).

W. Ostwald: Lehrbuch der Allgemeinen Chemie (Verlag von wilhelm engelmann, Leipzig, 1896).

Z.C. Liu, H.P. Ren, and H.Y. Wang: Austenite Formation and Pearlite Transformation (Metallurgical Industry Press, Beijing, China, 2010).

G.W. Greenwood: Mechanism of Phase Transformation in Crystalline Solids (Institute of Metals, London, UK, 1969).

ACKNOWLEDGMENTS

The authors are grateful for financial support from China National Science Foundation in Grant Nos. 50871082 and 51271137.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lian, F.L., Liu, H.J., Sun, J.J. et al. Ultrafine grain effect on pearlitic transformation in hypereutectoid steel. Journal of Materials Research 28, 757–765 (2013). https://doi.org/10.1557/jmr.2012.397

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2012.397