Abstract

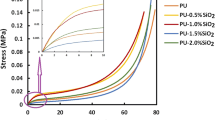

The isocyanate-functionalized silica nanoparticles were chemically incorporated into the polyurethane (PU) during the synthesis of flexible PU foam from polypropylene glycol and toluene diisocyanate following the one-shot method with water as the blowing agent. Chemical incorporations of silica nanoparticles augmented hardness, initial modulus, and strength for tensile and compression loading. As results, shape fixity, shape recovery, and strain energy storage significantly increased with reduced hysteresis loss. It was found that the chemically incorporated silica particles effectively reinforce the PUs with improved dispersion and act as multifunctional cross-links, elastic energy storage, and relaxation retarder, which are beyond the conventional reinforcing filler. The maximum increases of dynamic properties and shape memory performances with 2% silica are an indication that the chemical incorporation is also limited by particle aggregations, though it appears at higher content than the simple blend.

Similar content being viewed by others

REFERENCES

S.A. Madbouly and A. Lendlein: Shape-memory polymer composites. Adv. Polym. Sci. 226, 41 (2010).

C.M. Huang, K.H. Wei, U.S. Jeng, and H.S. Sheu: Pseudo-single-crystalline self-assembled structure formed from hydrophilic CdSe and hydrophobic Au nanoparticles in the polystyrene and poly(4-vinylpyridine) blocks, respectively, of a polystyrene-b-poly(4-vinylpyridine) diblock copolymer. Macromolecules 41, 6876 (2008).

W.F. Chen, J.S. Wu, and P-L. Kuo: Poly(oxyalkylene)diamine-functionalized carbon nanotube/perfluorosulfonated polymer composites: Synthesis, water state, and conductivity. Chem. Mater. 20, 5756 (2008).

Y. Okumura, C. Oi, W. Sakamoto, and T. Yogo: Synthesis of SrTiO3 nanoparticle/polymer composite film using direct current field. J. Mater. Res. 23, 127 (2008).

M.J. Lance, C-H. Hsueh, I.N. Ivanov, and D.B. Geohegan: Reorientation of carbon nanotubes in polymer matrix composites using compressive loading. J. Mater. Res. 20, 1026 (2005).

A. Kelly: Composites in context. Compos. Sci. Technol. 23, 171 (1985).

E.T. Thostenson, C. Li, and T.W. Chou: Nanocomposites in context. Compos. Sci. Technol. 65, 491 (2005).

Q. Fabrizio, S. Loredana, and S.E. Anna: Shape memory epoxy foams for space applications. Mater. Lett. 69, 20 (2012).

M.K. Jang, A. Hartwig, and B.K. Kim: Shape memory polyurethanes cross-linked by surface modified silica particles. J. Mater. Chem. 19, 1166 (2009).

D.H. Jung, H.M. Jeong, and B.K. Kim: Organic–inorganic chemical hybrids having shape memory effect. J. Mater. Chem. 20, 3458 (2010).

C.Y. Bae, J.H. Park, E.Y. Kim, Y.S. Kang, and B.K. Kim: Organic–inorganic nanocomposite bilayers with triple shape memory effect. J. Mater. Chem. 21, 11288 (2011).

S.H. Lee, J.W. Kim, and B.K. Kim: Shape memory polyurethanes having crosslinks in soft and hard segments. Smart Mater. Struct. 13, 1345 (2004).

A. Aneja and G.L. Wilkes: On the issue of urea phase connectivity in formulations based on molded flexible polyurethane foams. J. Appl. Polym. Sci. 85, 2956 (2002).

B.D. Kaushiva and G.L. Wilkes: Uniaxial orientation behavior and consideration of the geometric anisotropy of polyurea hard domain structure in flexible polyurethane foams. Polymer 41, 6987 (2000).

B.D. Kaushiva, S.R. McCartney, G.R. Rossny, and G.L. Wilkes: Surfactant level influences on structure and properties of flexible slabstock polyurethane foams. Polymer 41, 285 (2000).

N.M.K. Lamba, K.A. Woodhouse, and S.L. Cooper: Polyurethanes in Biomedical Applications (CRC Press, Boston, MA, 1998).

R. Neff, A. Adedeji, C.W. Macosko, and A.J. Ryan: Urea hard segment morphology in flexible polyurethane foam. J. Polym. Sci., Part B: Polym. Phys. 36, 573 (1998).

H. Tobushi, K. Okumura, M. Endo, and S. Hayashi: Thermomechanical properties of polyurethane-shape memory polymer foam. J. Intell. Mater. Syst. Struct. 12, 283 (2001).

H. Tobushi, R. Matsui, S. Hayashi, and D. Shimada: The influence of shape-holding conditions on shape recovery of polyurethane-shape memory polymer foams. Smart Mater. Struct. 13, 881 (2004).

C. Liu, H. Qin, and P.T. Mather: Review of progress in shape-memory polymers J. Mater. Chem. 17, 1543 (2007).

ACKNOWLEDGMENTS

This work was supported by the National Research Foundation of Korea grant funded by the Korean government through GCRC-SOP (Grant No. 2011-0030668).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kang, S., Kim, M., Kwon, S. et al. Polyurethane foam/silica chemical hybrids for shape memory effects. Journal of Materials Research 27, 2837–2843 (2012). https://doi.org/10.1557/jmr.2012.334

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2012.334