Abstract

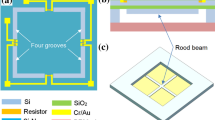

To overcome the low fabrication yield associated with single crystalline 3C–SiC diaphragm-based high temperature capacitive pressure sensors fabricated by wafer bonding, we have developed an alternative based on a polycrystalline SiC-on-Si architecture. The capacitive pressure sensing element, i.e., a thin film diaphragm, was fabricated using low stress and high conductivity low-pressure chemical vapor deposition poly-SiC thin films, and the sensing architecture was formed by wafer bonding a poly-SiC film to a Si substrate using phosphosilicate glass bonding films. With a geometric aspect ratio of up to 800:1 and a maximum deflection load eight times or more to their thickness, the poly-SiC diaphragm-based sensors presented repeatable pressure sensing characteristics up to 500 °C.

Similar content being viewed by others

References

G. Krotz, W. Legner, C. Wagner, H. Moller, H. Sonntag, and G. Muller: Silicon carbide as a mechanical material. Transducers 95, 186 (1995).

M. Mehregany: Silicon carbide for microelectromechanical systems. Int. Mater. Rev. 45, 85 (2000).

L. Tong, M. Mehregany, and L.G. Matus: Silicon carbide as a new micromechanics material. IEEE Solid-State Sens. Actuators 198 (1992).

National Research Council: Materials for High-Temperature Semiconductor Devices (National Academy Press, Washington, DC, 1995).

A.A. Ned, R.S. Okojie, and A.D. Kurtz: 6H-SiC pressure sensor operation at 600 °C. HITEC 257 (1998).

R.S. Okojie, J.C. DeLaat, and J.R. Saus: SiC pressure sensor for detection of combustor thermoacoustic instabilities [aircraft engine applications]. In 13th International Conference on Solid-State Sensors, Actuators. and Microsystems, (IEEE, Piscataway, NJ, 2005); p. 470.

R.S. Okojie, A.A. Ned, and A.D. Kurtz: Operation of α (6H)-SiC pressure sensor at 500 °C. Sens.Actuators, A 66, 200 (1998).

R.S. Okojie, A.A. Ned, A.D. Kurtz, and W.N. Carr: α(6H)-SiC pressure sensors at 350 °C. Int. Electron. Devices Meetings 525 (1996).

C-H. Wu, S. Stefanescu, H-I. Kuo, C.A. Zorman, M. Mehregany, and E. Obermeier: Fabrication and testing of single crystalline 3C-SiC piezoresistive pressure sensors. In International Conference on Solid State Sensors and Actuators, (Springer, New York, NY, 2001); p. 514.

D. Hammerschmidt, F.V. Schnatz, W. Brockherde, B.J. Hosticka, and E. Obermeier: A CMOS piezoresistive pressure sensor with on-chip programming and calibration. In IEEE International Solid-State Circuits Conference, (IEEE, Piscataway, NJ, 1993); p. 128.

J.S. Shor, L. Bemis, and A.D. Kurtz: Characterization of monolithic n-type 6H-SiC piezoresistive sensing elements. IEEE Trans. Electron. Devices 41, 661 (1994).

J.S. Shor, D. Goldstein, and A.D. Kurtz: Characterization of n-type β-SiC as a piezoresistor. IEEE Trans. Electron. Devices 40, 1093 (1993).

C.H. Wu, C.A. Zorman, and M. Mehregany: Fabrication and testing of bulk micromachined silicon carbide piezoresistive pressure sensors for high temperature applications. IEEE Sens. J. 6, 316 (2006).

W.H. Ko and Q. Wang: Touch mode capacitive pressure sensors. Sens. Actuators, A 75, 242 (1999).

W.H. Ko, Q. Wang, and Y. Wang: Touch mode capacitive pressure sensors for industrial applications. In Solid-State Sensors and Actuators Workshop, (IEEE, Piscataway, NJ, 1996); p. 244.

M.A. Fonseca, J.M. English, M. von Arx, and M.G. Allen: Wireless micromachined ceramic pressure sensor for high-temperature applications. J. Microelectromech. Syst. 11, 337 (2002).

D.J. Young, J. Du, C.A. Zorman, and W.H. Ko: High-temperature single-crystal 3C-SiC capacitive pressure sensor. IEEE Sensors J. 4, 464 (2004).

J. Du, W.H. Ko, M. Mehregany, and C.A. Zorman: Poly-SiC capacitive pressure sensors made by wafer bonding. In IEEE Conference on Sensors, (IEEE, Piscataway, NJ, 2005); p. 1268.

L. Chen and M. Mehregany: A silicon carbide capacitive pressure sensor for high temperature and harsh environment applications. In Transducers’ 2007, (IEEE, Piscataway, NY, 2007); p. 2597.

L. Chen and M. Mehregany: A silicon carbide capacitive pressure sensor for in-cylinder pressure measurement. Sens. and Act. A (Phy.) 145–146, 2 (2008).

Q. Wang: Touch mode capacitive pressure sensors and interface circuits. Ph.D. Dissertation, Case Western Reserve University, Cleveland, 1998.

W.P. Eaton, F. Bitsie, J.H. Smith, and D.W. Plummer: A new analytical solution for diaphragm deflection and its application to a surface-micromachined pressure sensor. In Proceedings International Conference on Modeling and Simulation of. Microsystems, Semiconductors, Sensors and Actuators, (Nano Science and Technology Institute, Danville, CA, 1999); p. 640.

S. Timoshenko: Theory of Plates and Shells (McGraw-Hill, Columbus, OH, 1959).

J.L. Dunning: Development of low-stress, undoped poly-SiC films in a large-scale LPCVD furnace using gas flow as a controlling parameter. M.S. Thesis, Case Western Reserve University, Cleveland, 2005.

J. Trevino, F. Xiao-An, M. Mehregany, and C. Zorman: Low-stress, heavily-doped polycrystalline silicon carbide for MEMS applications. In MEMS’ 2005, (IEEE, Piscataway, NJ, 2005); p. 451.

Q.-Y. Tong, U. Gosele, C. Yuan, A.J. Steckl, and M. Reiche: Silicon carbide wafer bonding. J. Electrochem. Soc. 142, 232 (1995).

W. Kern and G.L. Schnable: Chemically vapor-deposited borophosphosilicate glasses for silicon device applications. RCA Rev. 43, 423 (1982).

Yang: MOS capacitance measurements for high-leakage thin dielectrics. IEEE Trans. Electron. Devices 46, 1500 (1999).

Acknowledgments

The authors would like to thank Professor Wen H. Ko and Professor Mehran Mehregany with the EECS Department at Case Western Reserve University for constructive discussions. The authors gratefully acknowledge Mr. Ron Jezeski for maintaining the LPCVD deposition systems. Group member Allison Hess contributed the program code, which was later revised and enriched for the automated test setup. Andeen-Hagerling Inc. in Cleveland, OH, provided equipment for capacitance calibration. Device fabrication was performed in the Center for Micro- and Nano-Processing at Case Western Reserve University. This research was supported by the National Science Foundation under Grant No. ECS 0367274.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, J., Zorman, C.A. A polycrystalline SiC-on-Si architecture for capacitive pressure sensing applications beyond 400 °C: Process development and device performance. Journal of Materials Research 28, 120–128 (2013). https://doi.org/10.1557/jmr.2012.260

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2012.260