Abstract

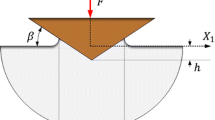

A method is presented for the identification of plastic material properties, i.e., yield strength and work hardening rate, using the residual imprint geometry formed by a spheroconical indentation. A corresponding finite element simulation with the same tip geometry and maximum as applied in the indentation experiment yields a numerical imprint profile. Then, the imprint profiles resulting from simulation and experiment are compared, and the material parameters of the simulation are varied by an optimization procedure until a satisfying agreement between simulation and experiment is established. At this stage, the material parameters used for the simulation represent the true material properties. It is shown that this procedure yields unique results that are furthermore verified by independent uniaxial straining experiments. Finally, the reliability of this method with special emphasis on its sensitivity with respect to measurement errors of the imprint geometry is demonstrated. Hence, it is concluded that the residual imprint can be regarded as the fingerprint of a material that contains sufficient information on plastic material behavior to uniquely extract values for yield strength and work hardening rate.

Similar content being viewed by others

References

W. Oliver and G. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

S. Suresh: Depth Sensing Indentation and Methodology for Mechanical Property Measurements. U.S. Patent No. WO 97/39333, 1997.

A.E. Giannakopoulos and S. Suresh: Method and Apparatus for Determination of Mechanical Properties of Functionally-Graded Materials. U.S. Patent No. 5,999,887, 1999.

T. Venkatesh, K.V. Vliet, A. Giannakopoulos, and S. Suresh: Determination of elasto-plastic properties by instrumented sharp indentation: Guidelines for property extraction. Scr. Mater. 42, 833–839 (2000).

M. Dao, N. Chollacoop, K.J.V Vliet, T.A. Venkatesh, and S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899–3918, (2001).

Y.P. Cao and J. Lu: A new method to extract the plastic properties of metal materials from an instrumented spherical indentation loading curve. Acta Mater. 52, 4023–4032 (2004).

Y.T. Cheng and C.M. Cheng: Can stress–strain relationships be obtained from indentation curves using conical and pyramidal indenters?J. Mater. Res. 14, 3493–3496 (1999).

X. Zhi-Hui and D. Rowcliffe: Method to determine the plastic properties of bulk materials by nanoindentation. Philos. Mag. A, 1893–1901: Taylor & Francis, Conference Paper, Journal Paper, Second International Indentation Workshop, 15–20 July 2001, Cambridge, UK.

J. Alkorta, J. Martinez-Esnaola, and J.G. Sevillano: Absence of one-to-one correspondence between elastoplastic properties and sharp-indentation load–penetration data. J. Mater. Res. 20, 432–437 (2005).

W. Capehart and Y.T. Cheng: Determining constitutive models from conical indentation: Sensitivity analysis. J. Mater. Res. 18(4), 6 (2003).

N. Chollacoop, M. Dao, and S. Suresh: Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713–3729 (2003).

L. Wang, M. Ganor, and S. Rokhlin: Inverse scaling functions in nanoindentation with sharp indenters: Determination of material properties. J. Mater. Res. 20, 987–1001 (2005).

X. Chen, N. Ogasawara, M. Zhao, and N. Chiba: On the uniqueness of measuring elastoplastic properties from indentation: The indistinguishable mystical materials. J. Mech. Phys. Solids 55, 1618–1660 (2007).

G. Valeriy, G. Frederick, and L. Hamed: Process for Determining Viscous, Elastic, Plastic, and Adhesive (Vepa) Properties of Materials Using AFM-Based or Conventional Nano-Indentation. The Patent Cooperation Treaty—Patent WO 2009/009595 A2, 2009.

B. Marco, B. Leonardo, and F. Vigilio: Method for Detecting Mechanical Features of a Material and Apparatus that Carries Out This Method. The Patent Cooperation Treaty—Patent WO 2006/013450 A2, 2006.

J.S. Field and M.V. Swain: Determining the mechanical properties of small volumes of material from submicrometer spherical indentations. J. Mater. Res. 10, 101–112 (1995).

H. Lan and T.A. Venkatesh: On the uniqueness and sensitivity issues in determining the elastic and plastic properties of power-law hardening materials through sharp and spherical indentation. Philos. Mag. 87, 4671–4729 (2007).

K. Matsuda: Prediction of stress-strain curves of elastic-plastic materials based on the Vickers indentation. Philos. Mag. A 82(10), 1941–1951 (2002).

B. Taljat, T. Zacharia, and F. Kosel: New analytical procedure to determine stress-strain curve from spherical indentation data. Int. J. Solids Struct. 35(33), 4411–4426 (1998).

G. Bolzon, G. Maier, and M. Panico: Material model calibration by indentation, imprint mapping and inverse analysis. Int. J. Solids Struct. 41, 2957–2975 (2004).

G. Polzer and F. Meißner: Fundamentals of Friction and Wear (VEB Deutscher Verlag für Grundstoffindustrie, Leipzig, Germany, 1982).

A. Yurkov, V. Skvortsov, I. Buyanovsky, and R. Matvievsky: Sliding friction of diamond on steel, sapphire, alumina and fused silica with and without lubricants. J. Mater. Sci. Lett. 16, 1370–1374 (1997).

G. Bolzon, M. Bocciarelli, and E.J. Chiarullo: Mechanical characterization of materials by micro-indentation and AFM scanning. Mech. Charact. Mater. 8, 1–108 (2008).

J. Nelder and R. Mead: A simplex method for function minimization. Comput. J. 7, 308–313 (1965).

E. Jones, T. Oliphant, and P. Peterson: (2001–) SciPy: Open source scientific tools for Python. (Online) Available: www.scipy.org.

MATLAB: Version 7.11.0 (R2010b) (The MathWorks Inc., Natick, MA, 2010).

C. Begau: Metamodel-based optimization of the welding line in extrusion simulations. Fakultaet für Informatik, Algorithm Engineering (LS 11), Technical University Dortmund, Tech. Rep., 2008.

D.R. Jones, M. Schonlau, and W.J. Welch: Efficient global optimization of expensive black-box functions. J. Global Optim. 13, 455–492 (1998).

Y.H. Lee, K. Takashima, Y. Higo, and D. Kwon: Prediction of stress directionality from pile-up morphology around remnant indentation. Scr. Mater. 51(9), 887–891 (2004).

Acknowledgments

The authors gratefully acknowledge support concerning the optimization strategy from Christoph Begau, as well as help with specimen preparation and laboratory work from Rehman Hameed, both from our institute. We further express thanks to ThyssenKrupp AG, Bayer Material Science AG, Salzgitter Mannesmann Forschung GmbH, Robert Bosch GmbH, Benteler Stahl/Rohr GmbH, Bayer Technology Services GmbH, and the state of North-Rhine Westphalia as well as the European Commission in the framework of the European Regional Development Fund (ERDF) for financial support and particularly thanks to the ThyssenKrupp AG for providing the multiphase steel material.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schmaling, B., Hartmaier, A. Determination of plastic material properties by analysis of residual imprint geometry of indentation. Journal of Materials Research 27, 2167–2177 (2012). https://doi.org/10.1557/jmr.2012.212

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2012.212