Abstract

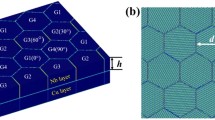

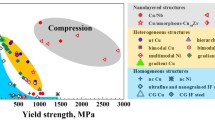

The effect of layer thickness on the hardness of nanometallic material composites with both coherent and incoherent interfaces was investigated using nanoindentation. Then, atomistic simulations were performed to identify the critical deformation mechanisms and explain the macroscopic behavior of the materials under investigation. Nanocomposites of different individual layer thicknesses, ranging from 1–30 nm, were manufactured and tested in nanoindentation. The findings were compared to the stress–strain curves obtained by atomistic simulations. The results reveal the role of the individual layer thickness as the thicker structures exhibit somehow different behavior than the thinner ones. This difference is attributed to the motion of the dislocations inside the layers. However, in all cases the hybrid structure was the strongest, implying that a particular improvement to the mechanical properties of the coherent nanocomposites can be achieved by adding a body-centered cubic layer on top of a face-centered cubic bilayer.

Similar content being viewed by others

REFERENCES

A. Misra, M.J. Demkowicz, J. Wang, and R.G. Hoagland: The multiscale modeling of plastic deformation in metallic nanolayered composites. JOM 60(4), 39 (2008).

R.G. Hoagland, R.J. Kurtz, and C.H. Henager Jr.: Slip resistance of interfaces and the strength of metallic multilayer composites. Scr. Mater. 50, 775 (2004).

J. Wang, R.G. Hoagland, and A. Misra: Mechanics of nanoscale metallic multilayers: From atomic-scale to micro-scale. Scr. Mater. 60(12), 1067 (2009).

A. Tokarz, T. Fraczek, Z. Balaga, and Z. Nitkiewicz: Structure, hardness and thermal stability of electrodeposited Cu/Ni nanostructured multilayers. Rev. Adv. Mater. Sci. 15(3), 247 (2007).

A. Misra, H. Kung, D. Hammon, R.G. Hoagland, and M. Nastasi: Damage mechanisms in nanolayered metallic composites. Int. J. Damage Mech. 12, 365 (2003).

A. Misra, J.P. Hirth, and R.G. Hoagland: Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 53(18), 4817 (2005).

A. Misra and R.G. Hoagland: Effects of elevated temperature annealing on the structure and hardness of copper/niobium nanolayered films. J. Mater. Res. 20(8), 2046 (2005).

C.A. Schuh, T.G. Nieh, and T. Yamasaki: Hall-Petch breakdown manifested in abrasive wear resistance of nanocrystalline nickel. Scr. Mater. 46(10), 735 (2002).

H. Conrad and J. Narayan: Mechanisms for grain size hardening and softening in Zn. Acta Mater. 50(20), 5067 (2002).

S. Yip: Nanocrystals—The strongest size. Nature 391(6667), 532 (1998).

H.S. Kim, Y. Estrin, and M.B. Bush: Plastic deformation behaviour of fine-grained materials. Acta Mater. 48(2), 493 (2000).

Y.B. Wang, B.Q. Li, M.L. Sui, and S.X. Mao: Deformation-induced grain rotation and growth in nanocrystalline Ni. Appl. Phys. Lett. 92(1), 011903 (2008).

W.D. Nix: Yielding and strain hardening of thin metal films on substrates. Scr. Mater. 39(4/5), 545 (1998).

F. Akasheh, H.M. Zbib, J.P. Hirth, R.G. Hoagland, and A. Misra: Dislocation dynamics analysis of dislocation intersections in nanoscale multilayer metallic composites. J. Appl. Phys. 101, 084314 (2007).

L.B. Freund: The stability of a dislocation threading a strained layer on a substrate. J. Appl. Mech. Techol Phys. 54(3), 553 (1987).

R.G. Hoagland, T.E. Mitchell, J.P. Hirth, and H. Kung: On the strengthening effects of interfaces in multilayer fcc metallic composites. Philos. Mag. A 82(4), 643 (2002).

I.N. Mastorakos, H.M. Zbib, and D.F. Bahr: Deformation mechanisms and strength in metallic nanolaminate composites with coherent and incoherent interfaces. Appl. Phys. Lett. 94 (17), 054117 (2009).

N.R. Overman, C.T. Overman, H.M. Zbib, and D.F. Bahr: Yield and deformation in biaxially stressed multilayer metallic thin films. J. Eng. Mater. Techol. 131(4), 041203 (2009).

I.N. Mastorakos, N. Abdolrahim, and H.M. Zbib: Deformation mechanisms in composite nano-layered metallic and nanowire structures. Int. J. Mech. Sci. 52, 295 (2010).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117(1), (1995).

M. Daw and M. Baskes: Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443 (1983).

A.F. Voter and S.P. Chen: Accurate Interatomic Potentials for Ni, Al and Ni3Al, in Characterization of Defects in Materials, edited by R.W. Siegel, J.R. Weertman, and R. Sinclair (Mater. Res. Soc. Symp. Proc. 82, Pittsburgh, PA, 1987), p. 175.

R.A. Johnson: Alloy models with the embedded atom method. Phys. Rev. B 39(17), 12554 (1989).

Y. Mishin, M.J. Mehl, D.A. Papaconstantopoulos, A.F. Voter, and J.D. Kress: Structural stability and lattice defects in copper: Ab initio, tight-binding and embedded-atom calculations. Phys. Rev. B 63, 224106 (2001).

R.A. Johnson and D.J. Oh: Analytic embedded atom method model for bcc. J. Mater. Res. 4(5), 1195 (1989).

Q. Zhang, W.S. Lai, and B.X. Liu: Atomic structure and physical properties of Ni-Nb amorphous alloys determined by an n-body potential. J. Non-Cryst. Solids 261, 137 (2000).

M.J. Demkowicz and R.G. Hoagland: Structure of Kurdjumov-Sachs interfaces in simulations of a copper-niobium bilayer. J. Nucl. Mater. 372, 45 (2008).

S. Melchionna, G. Ciccotti, and B.L. Holian: Hoover NPT dynamics for systems varying in shape and size. Mol. Phys. 78, 533 (1993).

C.H. Henager Jr., R.J. Kuntz, and R.G. Hoagland: Interactions of dislocations with disconnections in fcc metallic nanolayered materials. Philos. Mag. 84(22), 2277 (2004).

R.G. Hoagland, J.P. Hirth, and A. Misra: On the role of weak interfaces in blocking slip in nanoscale layered composites. Philos. Mag. 86(23), 3537 (2006).

P.M. Anderson, J.F. Bingert, A. Misra, and J.P. Hirth: Rolling textures in nanoscale Cu/Nb multilayers. Acta Mater. 51(20), 6059 (2003).

A. Misra, J.P. Hirth, and H. Kung: Single-dislocation-based strengthening mechanisms in nanoscale metalic multilayers. Philos. Mag. A 82(16), 2935 (2002).

L. Lu, X. Chen, X. Huang, and K. Lu: Revealing the maximum strength in nanotwinned copper. Science 3232, 607 (2009).

K. Nyilas, A. Misra, and T. Ungar: Micro-strains in cold rolled Cu–Nb nanolayered composites determined by X-ray line profile analysis. Acta Mater. 54(3), 751 (2005).

N.A. Mara, D. Bhattacharyya, R.G. Hoagland, and A. Misra: Tensile behavior of 40 nm Cu/Nb nanoscale multilayers. Scr. Mater. 58(10), 874 (2008).

A. Bellou, C.T. Overman, H.M. Zbib, D.F. Bahr, and A. Misra: Strength and strain hardening behavior of Cu-based bilayers and trilayers. Scr. Mater. 64, 641 (2011).

ACKNOWLEDGMENT

This work was supported by the U.S. Department of Energy under Grant No. DE-FG02-07ER46435. The authors acknowledge R.G. Hoagland for many fruitful discussions and A. Misra and the Materials Science and Technology Division at Los Alamos National Laboratory for the manufacturing of the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mastorakos, I.N., Bellou, A., Bahr, D.F. et al. Size-dependent strength in nanolaminate metallic systems. Journal of Materials Research 26, 1179–1187 (2011). https://doi.org/10.1557/jmr.2011.120

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.120