Abstract

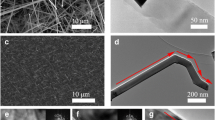

A novel and previously unreported, high temperature solid–liquid–solid (SLS) silica nanowire (NW) growth mode has been observed and investigated. In this mode, SLS NW nucleation and subsequent growth was uniquely promoted by—and coupled to—the formation of thermally etched pyramidal pits in the Si substrate that formed during a high temperature anneal phase before the onset of SLS NW formation. The silicon oxide-mediated thermal pit formation process enhanced Si transport to Au–Si alloy droplets directly adjacent to the pyramidal pits. Consequently, SLS NW nucleation and growth was preferentially promoted at the pit edges. The promotion of SLS NW growth by the pyramidal pits resulted in the observation of SLS NW “blooms” at the pit locations. Subsequent NW growth, occurring both at the pit sites and from Au–Si alloy droplets distributed across the planar surfaces of the Si wafer, eventually occluded the pits. This newly observed process is termed as “thermal pit-assisted growth.”

Similar content being viewed by others

References

A.M. Morales and C.M. Lieber: A laser ablation method for the synthesis of crystalline semiconductor nanowires. Science 279, 208 (1998).

W. Lu and C.M. Lieber: Nanoelectronics from the bottom up. Nat. Mater. 6, 841 (2007).

A. Colli, A. Fasoli, P. Beecher, P. Servati, S. Pisana, Y. Fu, A.J. Flewitt, W.I. Milne, J. Robertson, C. Ducati, S. De Franceschi, S. Hofmann, and A.C. Ferrari: Thermal and chemical vapor deposition of Si nanowires: Shape control, dispersion, and electrical properties. J. Appl. Phys. 102, 034302 (2007).

Y. Wu, J. Xiang, C. Yang, W. Lu, and C.M. Lieber: Single-crystal metallic nanowires and metal/semiconductor nanowire heterostructures. Nature 430, 61 (2004).

Y.F. Zhang, Y.H. Tang, N. Wang, D.P. Yu, C.S. Lee, I. Bello, and S.T. Lee: Silicon nanowires prepared by laser ablation at high temperature. Appl. Phys. Lett. 721, 835 (1998).

N.D. Zakharov, P. Werner, G. Gerth, L. Schubert, L. Sokolov, and U. Gösele: Growth phenomena of Si and Si/Ge nanowires on Si (111) by molecular beam epitaxy. J. Cryst. Growth 290, 6 (2006).

D.P. Yu, Z.G. Bai, Y. Ding, Q.L. Hang, H.Z. Zhang, J.J. Wang, Y.H. Zou, W. Qian, G.C. Xiong, H.T. Zhou, and S.Q. Feng: Nanoscale silicon wires synthesized using simple physical evaporation. Appl. Phys. Lett. 72, 3458 (1998).

J. Westwater, D.P. Gosain, S. Tomiya, S. Usui, and H. Ruda: Growth of silicon nanowires via gold/silane vapor–liquid–solid reaction. J. Vac. Sci. Technol., B 15, 554 (1997).

Y. Cui, L.J. Lauhon, M.S. Gudiksen, J. Wang, and C.M. Lieber: Diameter-controlled synthesis of single-crystal silicon nanowires. Appl. Phys. Lett. 78, 2214 (2001).

A.I. Hochbaum, R. Fan, R. He, and P. Yang: Controlled growth of Si nanowire arrays for device integration. Nano Lett. 5, 457 (2005).

M. Paulose, O.K. Varghese, and C.A. Grimes: Synthesis of gold-silica composite nanowires through solid-liquid-solid phase growth. J. Nanosci. Nanotechnol. 3, 341 (2003).

H.F. Yan, Y.J. Xing, Q.L. Hang, D.P. Yu, Y.P. Wang, J. Xu, Z.H. Xi, and S.Q. Feng: Growth of amorphous silicon nanowires via a solid–liquid–solid mechanism. Chem. Phys. Lett. 323, 224 (2000).

R.S. Wagner and W.C. Ellis: Vapor-liquid-solid mechanism of single crystal growth. Appl. Phys. Lett. 4, 89 (1964).

E.I. Givargizov: Fundamental aspects of VLS growth. J. Cryst. Growth 31, 20 (1975).

R.Q. Zhang, Y. Lifshitz, and S.T. Lee: Oxide-assisted growth of semiconducting nanowires. Adv. Mater. 15, 635 (2003).

R.Q. Zhang, T.S. Chu, H.F. Cheung, N. Wang, and S.T. Lee: Mechanism of oxide-assisted nucleation and growth of silicon nanostructures. Mater. Sci. Eng., C 16, 31 (2001).

R.Q. Zhang, T.S. Chu, H.F. Cheung, N. Wang, and S.T. Lee: High reactivity of silicon suboxide clusters. Phys. Rev. B 64, 113304 (2001).

J.H. Lee, P.H. Rogers, M.A. Carpenter, E.T. Eisenbraun, Y. Xue, and R.E. Geer: Synthesis and properties of templated Si-based nanowires for electrical transport, in Proceedings of Eighth IEEE Conference on Nanotechnology, IEEE NANO’ 08, Arlington, TX, 2008, p. 584.

P.K. Sekhar, N.S. Ramgir, R.K. Joshi, and S. Bhansali: Selective growth of silica nanowires using an Au catalyst for optical recognition of interleukin-10. Nanotechnology 19, 245502 (2008).

J.H. Kim, H.H. An, H.J. Woo, and C.S. Yoon: The growth mechanism for silicon oxide nanowires synthesized from an Au nanoparticle/polyimide/Si thin film stack. Nanotechnology 19, 125604 (2008).

K. Ueda and M. Yoshimura: Formation of micromeshes by nickel silicide. Thin Solid Films 464, 208 (2004).

C.-C. Chang and P. Shen: Thermal-etching development of α-Zn2SiO4 polycrystals: Effects of lattice imperfections, Mn-dopant and capillary force. Mater. Sci. Eng., A 288, 42 (2000).

A. Reisman, S.T. Edwards, and P.L. Smith: On the thermal etching of silicon. J. Electrochem. Soc. 135, 2848 (1988).

A. Reisman, D. Temple, and P.L. Smith: Further comments on the thermal etching of silicon: The surface morphology of (100), (111) and (110) wafers in the temperature range 900°-1150°C. J. Electrochem. Soc. 137, 284 (1990).

G.R. Yazdi, M. Syvajarvi, and R. Yakimova: Formation of needle-like and columnar structures of AlN. J. Cryst. Growth 300, 130 (2007).

M. Futagami and M. Hamazaki: Thermal etching of a (100) silicon surface. Jpn. J. Appl. Phys. 21, 1782 (1982).

C.Y. Wang, L.H. Chan, D.Q. Xiao, T.C. Lin, and H.C. Shiha: Mechanism of solid-liquid-solid on the silicon oxide nanowire growth. J. Vac. Sci. Technol., B 24, 613 (2006).

J.L. Elechiguerra, J.A. Manriquez, and M.J. Yacaman: Growth of amorphous SiO2 nanowires on Si using a Pd/Au thin film as a catalyst. Appl. Phys. A Mater. Sci. Process. 79, 461 (2004).

G.W. Rubloff, R.M. Tromp, E.J. van Loenen, P. Balk, and F.K. LeGoues: Summary Abstract: High temperature decomposition of SiO2 at the Si/SiO2 interface. J. Vac. Sci. Technol., A 4, 1024 (1986).

R. Tromp, G.W. Rubloff, P. Balk, and F.K. LeGoues: High-temperature SiO2 decomposition at the SiO2/Si interface. Phys. Rev. Lett. 55, 2332 (1985).

T. Suzuki: Effect of annealing a silicon wafer in argon with a very low oxygen partial pressure. J. Appl. Phys. 88, 6881 (2000).

T. Suzuki: Relation between the suppression of the generation of stacking faults and the mechanism of silicon oxidation during annealing under argon containing oxygen. J. Appl. Phys. 88, 1141 (2000).

T. Suzuki: Oxygen partial pressure dependence of suppressing oxidation-induced stacking fault generation in argon ambient annealing including oxygen and HCl. Appl. Surf. Sci. 180, 168 (2001).

C.C. Surdu-Boba, J.L. Sullivana, S.O. Saieda, R. Layberrya, and M. Aflorib: Surface compositional changes in GaAs subjected to argon plasma treatment. Appl. Surf. Sci. 202, 183 (2002).

Z.W. Pan, Z.R. Dai, C. Ma, and Z.L. Wang: Molten gallium as a catalyst for the large-scale growth of highly aligned silica nanowires. J. Am. Chem. Soc. 124, 1817 (2002).

Acknowledgment

The authors acknowledge the SRC (Semiconductor Research Corporation)/DARPA (Defense Advanced Research Projects Agency) Focus Center Research Program and the New York State Office of Science, Technology and Research for their support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.H., Carpenter, M.A. & Geer, R.E. Novel growth mode of solid–liquid–solid (SLS) silica nanowires. Journal of Materials Research 26, 2232–2239 (2011). https://doi.org/10.1557/jmr.2011.119

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.119