Abstract

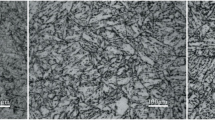

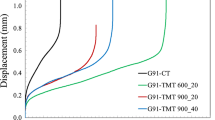

Welded joints of P92 steel subjected to creep testing at 650 °C and 70 MPa were investigated. Type IV cracking was observed in the fine-grained heat-affected zone (FGHAZ) of the welded joints by optical microscopy. It was found that with varying creep times, the number of creep voids increased at an accelerating rate and the maximum number of voids was formed in the FGHAZ. Scanning electron microscopy observations revealed that precipitates were formed in the interior of creep voids, suggesting that the nucleation of the creep voids is related to the precipitates. These creep voids then connected with each other, isolated the grain from the matrix, and formed zigzag microcracks, leading to type IV cracking. New coarse carbides—the Laves phase and Cr7C3—were precipitated during creep. These carbides can deteriorate the creep strength and stimulate the nucleation of creep voids in the FGHAZ.

Similar content being viewed by others

References

F. Abe, H. Okada, S. Wanikawa, M. Tabuchi, T. Itagaki, K. Kimura, K. Yamaguchi, and M. Igarashi: Guiding principles for development of advanced ferritic steels for 650 °C USC boilers, edited by J. Lecoute-Beckers, M. Carton, F. Schubert, and P.J. Ennis, in Proc. of Seventh Liege Conference on Materials for Advanced Power Engineering (Forschungszentrum Julich, Germany, 2002), p. 1397.

S. Fujibayashi, K. Kawano, T. Komamura, and T. Sugimura: Creep behavior of 2.25Cr–1Mo steel shield metal arc weldment. ISIJ Int. 44, 581 (2004).

J.C. Vaillant, B. Vandenberghe, B. Hahn, H. Heuser, and C. Jochum: T/P23, 24, 911 and 92: New grades for advanced coal-fired power plants–properties and experience. Int. J. Press. Vessels Pip. 85, 38 (2008).

C.D. Lundin, P. Liu, and Y. Cui: A literature review on characteristics of high temperature ferritic Cr–Mo steels and weldments, edited by C.D. Lundin (Welding Research Council, Inc., New York, WRC Bulletin 454, 2000).

H.K.D.H. Bhadeshia: Design of ferritic creep-resistant steels. ISIJ Int. 41, 626 (2001).

V. Knezevic, G. Sauthoff, J. Vilk, G. Inden, A. Schneider, R. Agamennone, W. Blum, Y. Wang, A. Scholz, C. Berger, J. Ehlers, and L. Singheiser: Martensitic/ferritic super heat-resistant 650 °C steels: Design and testing of model alloys. ISIJ Int. 42, 1505 (2002).

T. Fujita: Heat-resistant steels for advanced power plants. Adv. Mater. Processes 141, 42 (1992).

Z. Zhang, G.B. Holloway, and A.W. Marshall: Properties of T/P92 steel weld metals for ultra super critical (USC) power plant. Weld. World 52, 455 (2008).

M. Yoshizawa, M. Igarashi, K. Moriguchi, A. Iseda, H.G. Armaki, and K. Maruyama: Effect of precipitates on long-term creep deformation properties of P92 and P122 type advanced ferritic steels for USC power plants. Mater. Sci. Eng., A 510-511, 162 (2009).

K. Shinozaki, H.K. Dejun Li, H. Harada, K. Ohishi, and T. Sato: Observation of type IV cracking in welded joints of high chromium ferritic heat resistant steels. Sci. Technol. Weld. Joining 8, 289 (2003).

J.A. Francis, W. Mazur, and H.K.D.H. Bhadeshia: Estimation of type IV cracking tendency in power plant steels. ISIJ Int. 44, 1966 (2004).

J.A. Francis, W. Mazur, and H.K.D.H. Bhadeshia: Type IV cracking in ferritic power plant steels. Mater. Sci. Technol. 22, 1387 (2006).

D.J. Allen, B. Harvey, and S.J. Brett: “FOURCRACK”–An investigation of the creep performance of advanced high alloy steel welds. Int. J. Press. Vessels Pip. 84, 104 (2006).

P.J. Budden: Analysis of the Type IV creep failures of three welded ferrictic pressures vessels. Int. J. Press. Vessels Pip. 75, 509 (1998).

N. Komai and F. Masuyama: Microstructural degradation of the HAZ in 11Cr–0.4Mo–2W–V–Nb–Cu steel (P122) during creep. ISIJ Int. 42, 1364 (2002).

K. Sawada, M. Tabuchi, H. Hongo, T. Watanabe, and K. Kimura: Z-phase formation in welded joints of high chromium ferritic steels after long-term creep. Mater. Charact. 59, 1161 (2008).

Y. Li, H. Hongo, M. Tabuchi, Y. Takahashi, and Y. Monma: Evaluation of creep damage in heat affected zone of thick welded joint for Mod.9Cr–1Mo steel. Int. J. Press. Vessels Pip. 86, 585 (2009).

J. Hald: Microstructure and long-term creep properties of 9–12% Cr steels. Int. J. Press. Vessels Pip. 85, 30 (2008).

B. Kim and B. Lim: Local creep evaluation of P92 steel weldment by small punch creep test. Acta. Mech. Solida Sin. 21, 312 (2008).

S.H. Goods and L.M. Brown: Overview no. 1: The nucleation of cavities by plastic deformation. Acta Metall. 27, 1 (1979).

K. Shinozaki, D-J. Li, H. Kuroki, H. Harada, and K. Ohishi: Analysis of degradation of creep strength in heat-affected zone of weldment of high Cr heat-resisting steels based on void observation. ISIJ Int. 42, 1578 (2002).

P.J. Ennis, A. Zielinska-Lipiec, O. Wachter, and A. Czyrska-Filemonowicz: Microstructural stability and creep rupture strength of the martensitic steel P92 for advanced power plant. Acta Mater. 45, 4901 (1997).

M.T. Pérez-Prado and M.E. Kassner: Fundamentals of Creep in Metals and Alloys. 2nd ed. (Elsevier, Amsterdam, The Netherlands, 2008), p. 95.

S.K. Albert, M. Matsui, H. Hongo, T. Watanabe, K. Kubo, and M. Tabuchi: Creep rupture properties of HAZs of a high Cr ferritic steel simulated by a weld simulator. Int. J. Press. Vessels Pip. 81, 221 (2004).

H. Tezuka and T. Sakurai: A trigger of Type IV damage and a new heat treatment procedure to suppress it. Microstructural investigations of long-term ex-service Cr–Mo steel pipe elbows. Int. J. Press. Vessels Pip. 82, 165 (2005).

M. Sugesawa, T. Sakurai, M. Aoki, and K. Fukushima: Mechanism of creep damage in fine-grained heat affected zone of 2.25Cr–1Mo steel high temperature steam pipe (International Conference on Power Engineering, Shanghai, China, 1995), p. 1060.

Acknowledgments

The research work of this paper is supported by the National Nature Science Foundation of China (Contract No. 50805103), Tianjin Nature Science Foundation of China (Contract No. 08JCZDJC18100) and (Contract No. 08JCYBJC09100), the New Teacher Project in Specialized Research Fund for the Doctoral Program of Higher Education of China (Contract No. 20070056096), and Scientific Research Institute Technical Development Special Fund Project of the Ministry of Science and Technology of China (Ncste-2006-Jkzx-178).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, L., Jing, H., Xu, L. et al. Investigation on mechanism of type IV cracking in P92 steel at 650 °C. Journal of Materials Research 26, 934–943 (2011). https://doi.org/10.1557/jmr.2011.11

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.11