Abstract

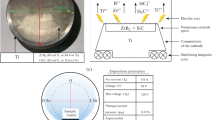

Ti–Si–C–N thin films were deposited onto WC-Co substrates by industrial scale arc evaporation from Ti3SiC2 compound cathodes in N2 gas. Microstructure and hardness were found to be highly dependent on the wide range of film compositions attained, comprising up to 12 at.% Si and 16 at.% C. Nonreactive deposition yielded films consisting of understoichiometric TiCx, Ti, and silicide phases with high (27 GPa) hardness. At a nitrogen pressure of 0.25–0.5 Pa, below that required for N saturation, superhard, 45–50 GPa, (Ti,Si)(C,N) films with a nanocrystalline feathered structure were formed. Films grown above 2 Pa displayed crystalline phases of more pronounced nitride character, but with C and Si segregated to grain boundaries to form weak grain boundary phases. In abundance of N, the combined presence of Si and C disturbs cubic phase growth severely and compromises the mechanical strength of the films.

Similar content being viewed by others

References

A. Flink, M. Beckers, J. Sjölen, T. Larsson, S. Braun, L. Karlsson, and L. Hultman: The location and effects of Si in (Ti1–xSi x)Ny thin films. J. Mater. Res. 24, 2483 (2009).

L. Karlsson, L. Hultman, M.P. Johansson, J.E. Sundgren, and H. Ljungcrantz: Growth, microstructure, and mechanical properties of arc evaporated TiC xN1–x (0 ≤ x ≤ 1) films. Surf. Coat. Techol. 126, 1 (2000).

S. Abraham, E.Y. Choi, N. Kang, and K.H. Kim: Microstructure and mechanical properties of Ti-Si-C-N films synthesized by plasma-enhanced chemical vapor deposition. Surf. Coat. Techol. 202, 915 (2007).

D.-H. Kuo and K.-W. Huang: A new class of Ti-Si-C-N coatings obtained by chemical vapor deposition, Part 1: 1000 °C process. Thin Solid Films 394, 72 (2001).

D.-H. Kuo and K.-W. Huang: A new class of Ti-Si-C-N coatings obtained by chemical vapor deposition—Part II: Low-temperature process. Thin Solid Films 394, 81 (2001).

D.-H. Kuo and W.-C. Liao: A new class of Ti-Si-C-N coatings obtained by chemical vapor deposition, Part III: 650–800 °C process. Thin Solid Films 419, 11 (2002).

Y. Guo, S.L. Ma, and K.W. Xu: Effects of carbon content and annealing temperature on the microstructure and hardness of super hard Ti-Si-C-N nanocomposite coatings prepared by pulsed d.c. PCVD. Surf. Coat. Techol. 201, 5240 (2007).

P. Jedrzejowski, J.E. Klemberg-Sapieha, and L. Martinu: Quaternary hard nanocomposite TiCxNy/SiCN coatings prepared by plasma enhanced chemical vapor deposition. Thin Solid Films 466, 189 (2004).

D.Y. Ma, S.L. Ma, H.S. Dong, K.W. Xu, and T. Bell: Microstructure and tribological behavior of super-hard Ti-Si-C-N nanocomposite coatings deposited by plasma enhanced chemical vapour deposition. Thin Solid Films 496, 438 (2006).

D.Y. Ma, S.L. Ma, and K.W. Xu: Superhard nanocomposite Ti-Si-C-N coatings prepared by pulsed-d.c plasma enhanced CVD. Surf. Coat. Techol. 200, 382 (2005).

D.V. Shtansky, E.A. Levashov, A.N. Sheveiko, and J.J. Moore: The structure and properties of Ti-B-N, Ti-Si-B-N, Ti-Si-C-N, and Ti-Al-C-N coatings deposited by magnetron sputtering using composite targets produced by self-propagating high-temperature synthesis (SHS). J. Mater. Synth. Process. 6, 61 (1998).

D.V. Shtansky, E.A. Levashov, A.N. Sheveiko, and J.J. Moore: Synthesis and characterization of Ti-Si-C-N films. Metall. Mater. Trans. A 30, 2439 (1999).

H. Xu, X. Nie, and R. Wei: Tribological behavior of a TiSiCN coating tested in air and coolant. Surf. Coat. Techol. 201, 4236 (2006).

R.H. Wei, E. Langa, C. Rincon, and J.H. Arps: Deposition of thick nitrides and carbonitrides for sand erosion protection. Surf. Coat. Techol. 201, 4453 (2006).

J.-H. Jeon, S.R. Choi, W.S. Chung, and K.H. Kim: Synthesis and characterization of quaternary Ti-Si-C-N coatings prepared by a hybrid deposition technique. Surf. Coat. Techol. 188-189, 415 (2004).

L.J.S. Johnson, L. Rogström, M.P. Johansson, M. Odén, and L. Hultman: Microstructure evolution and age hardening in (Ti, Si)(C, N) thin films deposited by cathodic arc evaporation. Thin Solid Films 519, 1397 (2010).

C.-L. Chang and T.-J. Hsieh: Effect of C2H2 gas flow rate on synthesis and characteristics of Ti-Si-C-N coating by cathodic arc plasma evaporation. J. Mater. Process. Technol. 209, 5521 (2009).

M.W. Barsoum: A new class of solids: Thermodynamically stable nanolaminates. Prog. Solid State Chem. 28, 201 (2000).

M.S. Jansson: CONTES, Conversion of Time-Energy Spectra—a Program for ERDA Data Analysis, Uppsala University, 2004.

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

A.O. Eriksson, J.Q. Zhu, N. Ghafoor, M.P. Johansson, J. Sjölén, J. Jensen, M. Odén, L. Hultman, and J. Rosén: Layer formation by resputtering in Ti-Si-C hard coatings during large scale cathodic arc deposition. Surf. Coat. Technol. DOI: 10.1016/j.surfcoat.2011.02.007 (2011).

Y. Guo, S.L. Ma, K.W. Xu, T. Bell, X.Y. Li, and H.S. Dong: On the oxidation resistance of superhard Ti-Si-C-N coatings.: J. Mater. Res. 23, 2420 (2008).

PDF: TiN 00-038-1420, TiC 00-032-1383, Ti 00-044-1294, TiSi2 00-035-0785, Ti5Si3 00-029-1362, ICDD “Powder Diffraction File” (2008).

J.A. Sue: X-ray elastic constants and residual stress of textured titanium nitride coating. Surf. Coat. Techol. 54-55, 154 (1992).

A. Flink, T. Larsson, J. Sjölen, L. Karlsson, and L. Hultman: Influence of Si on the microstructure of arc evaporated (Ti, Si)N thin films; evidence for cubic solid solutions and their thermal stability. Surf. Coat. Techol. 200, 1535 (2005).

T. Marten, E.I. Isaev, B. Alling, L. Hultman, and I.A. Abrikosov: Single-monolayer SiNx embedded in TiN: A first-principles study. Phys. Rev. B 81, 212102 (2010).

L. Hultman, J. Bareño, A. Flink, H. Söderberg, K. Larsson, V. Petrova, M. Odén, J.E. Greene, and I. Petrov: Interface structure in superhard TiN-SiN nanolaminates and nanocomposites: Film growth experiments and ab initio calculations. Phys. Rev. B 75, 155437 (2007).

A. Snis and S.F. Matar: Electronic density of states, 1s core-level shifts, and core ionization energies of graphite, diamond, C3N4 phases, and graphitic C11N4. Phys. Rev. B 60, 10855 (1999).

Y.H. Lu, Y.G. Shen, Z.F. Zhou, and K.Y. Li: Phase configuration, nanostructure evolution, and mechanical properties of unbalanced magnetron-sputtered Ti-Cx-Ny thin films. J. Vac. Sci. Technol. A 25, 1539 (2007).

N. Hellgren, M.P. Johansson, E. Broitman, L. Hultman, and J.-E. Sundgren: Role of nitrogen in the formation of hard and elastic CNx thin films by reactive magnetron sputtering. Phys. Rev. B 59, 5162 (1999).

J. Neidhardt, L. Hultman, and Z. Czigány: Correlated high resolution transmission electron microscopy and x-ray photoelectron spectroscopy studies of structured CNx (0 < x < 0.25) thin solid films. Carbon 42, 2729 (2004).

A. Anders: A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films 518, 4087 (2010).

A. Anders: Cathodic Arcs, Chapter 6 (Springer, New York, 2008).

J. Rosén, A. Anders, S. Mraz, A. Atiser, and J.M. Schneider: Influence of argon and oxygen on charge-state-resolved ion-energy distributions of filtered aluminum arcs. J. Appl. Phys. 99, 123303 (2006).

P. Eklund: Novel ceramic Ti-Si-C nanocomposite coatings for electrical contact applications. Surf. Eng. 23, 406 (2007).

Acknowledgments

This work was funded by the VINN Excellence center on Functional Nanoscale Materials (FunMat). The authors also acknowledge Uppsala University for access to the Tandem Laboratory for ERDA analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eriksson, A.O., Zhu, J., Ghafoor, N. et al. Ti–Si–C–N thin films grown by reactive arc evaporation from Ti3SiC2 cathodes. Journal of Materials Research 26, 874–881 (2011). https://doi.org/10.1557/jmr.2011.10

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.10