Abstract

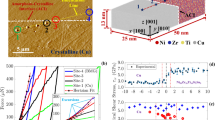

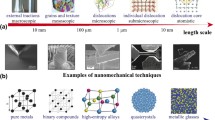

Low-load nanoindentation can be used to assess not only the plastic yield point, but the distribution of yield points in a material. This paper reviews measurements of the so-called nanoscale strength distribution (NSD) on two classes of materials: crystals and metallic glasses. In each case, the yield point has a significant spread (10-50% of the mean normalized stress), but the origins of the distribution are shown to be very different in the two materials classes. In crystalline materials the NSD can arise from thermal fluctuations and is attended by significant rate and temperature dependence. In metallic glasses well below their glass-transition temperature, the NSD is reflective of fluctuations in the sampled structure and is not very sensitive to rate or temperature. Computer simulations using shear transformation zone dynamics are used to separate the effects of thermal and structural fluctuations in metallic glasses, and support the latter as dominating the NSD of those materials at low temperatures. Finally, the role of the NSD as a window on structural changes due to annealing or prior deformation is discussed as a direction for future research on metallic glasses in particular.

Similar content being viewed by others

References

D.F. Bahr and G. Vasquez: Effect of solid solution impurities on dislocation nucleation during nanoindentation. J. Mater. Res. 20, 1947 (2005).

D.F. Bahr, D.E. Wilson, and D.A. Crowson: Energy considerations regarding yield points during indentation. J. Mater. Res. 14, 2269 (1999).

A.C. Lund, A.M. Hodge, and C.A. Schuh: Incipient plasticity during nanoindentation at elevated temperatures. Annl. Phys. Lett. 85, 1362 (2004).

J.K. Mason, A.C. Lund, and C.A. Schuh: Determining the activation energy and volume for the onset of plasticity during nanoindentation. Phys. Rev. B 73, 054102 (2006).

T.A. Michalske and J.E. Houston: Dislocation nucleation at nanoscale mechanical contacts. Acta Mater. 46, 391 (1998).

S. Suresh, T.G. Nieh, and B.W. Choi: Nano-indentation of copper thin films on silicon substrates. Scr. Mater. 41, 951 (1999).

S.G. Corcoran, R.J. Colton, E.T. Lilleodden, and W.W. Gerberich: Anomalous plastic deformation at surfaces: Nanoindentation of gold single crystals. Phys. Rev. B 55, 16057 (1997).

H. Bei, Z.P. Lu, and E.P. George: Theoretical strength and the onset of plasticity in bulk metallic glasses investigated by nanoindentation with a spherical indenter. Phys. Rev. Lett. 93, 125504 (2004).

C.E. Packard and C.A. Schuh: Initiation of shear bands near a stress concentration in metallic glass. Acta Mater. 55, 5348 (2007).

W.J. Wright, R. Saha, and W.D. Nix: Deformation mechanisms of the Zr40Ti14Ni10Cu12Be24 bulk metallic glass. Mater. Trans. 42, 642 (2001).

Y.F. Shi and M.L. Falk: Stress-induced structural transformation and shear banding during simulated nanoindentation of a metallic glass. Acta Mater. 55, 4317 (2007).

E.R. Homer and C.A. Schuh: Mesoscale modeling of amorphous metals by shear transformation zone dynamics. Acta Mater. 57, 2823 (2009).

J. Li, K.J. Van Vliet, T. Zhu, S. Yip, and S. Suresh: Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307 (2002).

K.J. Van Vliet, J. Li, T. Zhu, S. Yip, and S. Suresh: Quantifying the early stages of plasticity through nanoscale experiments and simulations. Phys. Rev. B 67, 104105 (2003).

O. Franke, K. Durst, and M. Goken: Nanoindentation investigations to study solid solution hardening in Ni-based diffusion couples. J. Mater. Res. 24, 1127 (2009).

O. Franke, K. Durst, and M. Goken: Microstructure and local mechanical properties of Pt-modified nickel aluminides on nickel-base superalloys after fhermo-mechanical fatigue. Mater. Sci. Eng., A 467, 15 (2007).

K. Tai, M. Dao, S. Suresh, A. Palazoglu, and C. Ortiz: Nanoscale heterogeneity promotes energy dissipation in bone. Nat. Mater. 6, 454 (2007).

C.A. Tweedie, D.G. Anderson, R. Langer, and K.J. Van Vliet: Combinatorial material mechanics: High-throughput polymer synthesis and nanomechanical screening. Adv. Mater. 17, 2599 (2005).

G. Constantinides, K.S.R. Chandran, F.J. Ulm, and K.J. Van Vliet: Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater. Sci. Ens.. A 430, 189 (2006).

J.C. Zhao, M.R. Jackson, L.A. Peluso, and L.N. Brewer: A diffusion-multiple approach for mapping phase diagrams, hardness, and elastic modulus. JOM 54, 42 (2002).

C.A. Schuh and A.C. Lund: Application of nucleation theory to the rate dependence of incipient plasticity during nanoindentation. J. Mater. Res. 19, 2152 (2004).

C.A. Schuh, J.K. Mason, and A.C. Lund: Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nat. Mater. 4, 617 (2005).

C.E. Packard, E.R. Homer, N. Al-Aqeeli, and C.A. Schuh: Cyclic hardening of metallic glasses under Hertzian contacts: Experiments and STZ dynamics simulations. Philos. Mas. 90, 1373 (2010).

C.E. Packard, L.M. Witmer, and C.A. Schuh: Hardening of a metallic glass during cyclic loading in the elastic range. Appl. Phys. Lett. 92, 171911 (2008).

A.C. Fischer-Cripps: Introduction to Contact Mechanics (Springer, New York, 2000).

H. Hertz: Miscellaneous Papers, translated by D.E. Jones and G.A. Schott (Macmillan, London, 1896).

P.C. Wo, L. Zuo, and A.H.W. Ngan: Time-dependent incipient plasticity in Ni3Al as observed in nanoindentation. J. Mater. Res. 20, 489 (2005).

K.V. Rajulapati, M.M. Biener, J. Biener, and A.M. Hodge: Temperature dependence of the plastic flow behavior of tantalum. Philos. Mac. Lett. 90, 35 (2010).

W.W. Gerberich, J.C. Nelson, E.T. Lilleodden, P. Anderson, and J.T. Wyrobek: Indentation induced dislocation nucleation: The initial yield point. Acta Mater. 44, 3585 (1996).

M.M. Biener, J. Biener, A.M. Hodge, and A.V. Hamza: Dislocation nucleation in bcc Ta single crystals studied by nanoindentation. Phys. Rev. B 76, 165422 (2007).

C.A. Schuh and T.G. Nieh: A survey of instrumented indentation studies on metallic glasses. J. Mater. Res. 19, 46 (2004).

K. Durst, B. Backes, O. Franke, and M. Goken: Indentation size effect in metallic materials: Modeling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 54, 2547 (2006).

E.K. Njeim and D.F. Bahr: Atomistic simulations of nanoindentation in the presence of vacancies. Scr. Mater. 62, 598 (2010).

S. Shim, H. Bei, M.K. Miller, G.M. Pharr, and E.P. George: Effects of focused-ion-beam milling on the compressive behavior of directionally solidified micropillars and the nanoindentation response of an electropolished surface. Acta Mater. 57, 503 (2009).

B. Moser, J. Kuebler, H. Meinhard, W. Muster, and J. Michler: Observation of instabilities during plastic deformation by in-situ SEM indentation experiments. Adv. Ens. Mater. 7, 388 (2005).

B.G. Yoo, J.Y. Kim, and J.I. Jang: Influence of indenter geometry on the deformation behavior of Zr60Cu30Al10 bulk metallic glass during nanoindentation. Mater. Trans. 48, 1765 (2007).

C.A. Schuh and T.G. Nieh: A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 51, 87 (2003).

L. Wang, S.X. Song, and T.G. Nieh: Assessing plastic shear resistance of bulk metallic glasses under nanoindentation. Appl. Phys. Lett. 92, 3 (2008).

B. Yang and T.G. Nieh: Effect of the nanoindentation rate on the shear band formation in an Au-based bulk metallic glass. Acta Mater. 55, 295 (2007).

A.C. Fischer-Cripps: Nanoindentation (Springer, New York, 2002).

C.A. Schuh, T.G. Nieh, and Y. Kawamura: Rate dependence of serrated flow during nanoindentation of a bulk metallic glass. J. Mater. Res. 17, 1651 (2002).

N. Li, L. Liu, Q. Chen, J. Pan, and K.C. Chan: The effect of free volume on the deformation behaviour of a Zr-based metallic glass under nanoindentation. J. Phys. D: Appl. Phys. 40, 6055 (2007).

Y. Liu, T. Zhang, B. Wei, D. Xing, W. Li, and L. Zhang: Effect of structural relaxation on deformation behaviour of Zr-based metallic glass. Chin. Phys. Lett. 23, 1868 (2006).

B. Yang, J. Wadsworth, and T.G. Nieh: Thermal activation in Au-based bulk metallic glass characterized by high-temperature nanoindentation. Appl. Phys. Lett. 90, 061911 (2007).

K. Saksl, H. Franz, P. Jovari, K. Klementiev, E. Welther, A. Ehnes, J. Saida, A. Inoue, and J.Z. Jiang: Evidence of icosahedral short-range order in Zr70Cu30 and Zr70Cu29Pdi metallic glasses. Appl. Phys. Lett. 83, 3924 (2003).

J. Sietsma and B.J. Thijsse: An investigation of universal medium range order in metallic glasses. J. Non-Cryst. Solids 135, 146 (1991).

D.B. Miracle, T. Egami, K.M. Flores, and K.F. Kelton: Structural aspects of metallic glasses. MRS Bull. 32, 629 (2007).

K.M. Flores, E. Sherer, A. Bharathula, H. Chen, and Y.C. Jean: Sub-nanometer open volume regions in a bulk metallic glass investigated by positron annihilation. Acta Mater. 55, 3403 (2007).

K.M. Flores, B.P. Kanungo, S.C. Glade, and P. Asoka-Kumar: Characterization of plasticity-induced structural changes in a Zr-based bulk metallic glass using positron annihilation spectroscopy. J. Non-Crvst. Solids 353, 1201 (2007).

A.S. Argon: Plastic-deformation in metallic glasses. Acta Metall. 22, 47 (1979).

F. Spaepen: Microscopic mechanism for steady-state inhomogeneous flow in metallic glasses. Acta Metall. Mater. 25, 407 (1977).

J.S. Langer: Shear-transformation-zone theory of deformation in metallic glasses. Scr. Mater. 54, 375 (2006).

A.S. Argon and H.Y. Kuo: Free-energy spectra for inelastic deformation of 5 metallic-glass alloys. J. Non-Crvst. Solids 37, 241 (1980).

D. Rodney and C. Schuh: Distribution of thermally activated plastic events in a flowing glass. Phys. Rev. Lett. 102, 235503 (2009).

C.A. Schuh, A.C. Lund, and T.G. Nieh: New regime of homogeneous flow in the deformation map of metallic glasses: Elevated temperature nanoindentation experiments and mechanistic modeling. Acta Mater. 52, 5879 (2004).

D. Klaumunzer, R. Maass, F.H. Dalla Torre, and J.F. Loffler: Temperature-dependent shear band dynamics in a Zr-based bulk metallic glass. ADDI. Phys. Lett. 96, 061901 (2010).

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty: Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067 (2007).

C.E. Packard, J. Schroers, and C.A. Schuh: In situ measurements of surface tension-driven shape recovery in a metallic glass. Scr. Mater. 60, 1145 (2009).

N. Nishiyama, A. Inoue, and J.Z. Jiang: Elastic properties of Pd40Cu30Ni10P20 bulk glass in supercooled liquid region. Appl. Phys. Lett. 78, 1985 (2001).

W.L. Johnson and K. Samwer: A universal criterion for plastic yielding of metallic glasses with a (T/Tg)2/3 temperature dependence. Phys. Rev. Lett. 95, 195501 (2005).

E.R. Homer, D. Rodney, and C.A. Schuh: Kinetic Monte Carlo study of activated states and correlated shear-transformation-zone activity during the deformation of an amorphous metal. Phys. Rev. B 81, 064204 (2010).

E.R. Homer and C.A. Schuh: Three-dimensional shear transformation zone dynamics model for amorphous metals. Modell. Simul. Mater. Sci. Em. 18, 065009 (2010).

A. Slipenyuk and J. Eckert: Correlation between enthalpy change and free volume reduction during structural relaxation of Zr55Cu30Al10Ni5 metallic glass. Scr. Mater. 50, 39 (2004).

A. Vandenbeukel and J. Sietsma: The glass-transition as a free-volume related kinetic phenomenon. Acta Metall. Mater. 38, 383 (1990).

U. Ramamurty, M.L. Lee, J. Basu, and Y. Li: Embrittlement of a bulk metallic glass due to low-temperature annealing. Scr. Mater. 47, 107 (2002).

J.J. Lewandowski, W.H. Wang, and A.L. Greer: Intrinsic plasticity or brittleness of metallic glasses. Philos. Mas. Lett. 85, 77 (2005).

T. Mukai, T.G. Nieh, Y. Kawamura, A. Inoue, and K. Higashi: Dynamic response of a Pd40Ni40P20 bulk metallic glass in tension. Scr. Mater. 46, 43 (2002).

X. Hu, S.C. Ng, Y.P. Feng, and Y. Li: Glass forming ability and insitu composite formation in Pd-based bulk metallic glasses. Acta Mater. 51, 561 (2003).

J. Shen, Q.J. Chen, J.F. Sun, H.B. Fan, and G. Wang: Exceptionally high glass-forming ability of an FeCoCrMoCBY alloy. Appl. Phys. Lett. 86, 151907 (2005).

J.T. Trenkle, C.E. Packard, and C.A. Schuh: Hot nanoindentation in inert environments. Rev. Sci. Instrum. 81, 073901 (2010).

C.A. Schuh, C.E. Packard, and A.C. Lund: Nanoindentation and contact-mode imaging at high temperatures. J. Mater. Res. 21, 725 (2006).

Z.C. Duan and A.M. Hodge: High-temperature nanoindentation: New developments and ongoing challenges. JOM 61, 32 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/jmr_policy

This paper has been accepted as an Invited Feature Paper.

Rights and permissions

About this article

Cite this article

Packard, C.E., Franke, O., Homer, E.R. et al. Nanoscale strength distribution in amorphous versus crystalline metals. Journal of Materials Research 25, 2251–2263 (2010). https://doi.org/10.1557/jmr.2010.0299

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2010.0299