Abstract

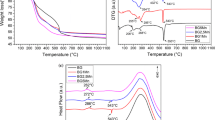

We report on the preparation of a bioactive CaO–SiO2 monolithic scaffold with interconnected bimodal nanomacro porosity, which simulates the morphology of a natural trabecular bone, by a newly developed modified sol-gel process. This method inherently creates nanopores, whose average diameter can be tailored to approximately 5–20 nm by solvent exchange. To achieve interconnected macroporosity (pores ~5–300 µm in size), a polymer [poly(ethylene oxide)] is added, which causes phase separation simultaneously with the sol-gel transition. High-resolution scanning electron microscopy and mercury intrusion porosimetry demonstrate a high degree of three-dimensional interconnectivity and sharp distributions of pore size. In vitro bioactivity tests in simulated body fluid (SBF) show bioactivity of the material after soaking for approximately 5 h, as verified by the formation of a hydroxyapatite layer deep into the scaffold structure. Analysis of the SBF after the reaction indicates the dissolution of the samples, another desired feature of temporary scaffolds for bone regeneration. MG63 osteoblast-like cells seeded on our sol-gel glass samples responded better to samples with nanopores enlarged by a solvent exchange process than to the one with normal nanopores. Thus, the benefits of the high surface area achieved by sol-gel and solvent exchange procedures are most clearly demonstrated for the first time.

Similar content being viewed by others

References

J.R. Jones, L.M. Ehrenfried, and L.L. Hench: Optimizing bioac-tive glass scaffolds for bone tissue engineering. Biomaterials 11. 964 (2006).

L.L. Hench, R.J. Splinter, W.C. Allen, and T.K. Greenlee Jr.: Bonding mechanisms at the interface of ceramic prosthetic materials. J. Biomed. Mater. Res. 2, 117 (1971).

M.M. Pereira and L.L. Hench: Mechanisms of hydroxyapatite formation on porous gel-silica substrates. J. Sol-Gel Sci. Technol. 7, 59 (1996).

T.M. Freyman, I.V. Yannas, and L.J. Gibson: Cellular materials as porous scaffolds for tissue engineering. Prog. Mater. Sci. 46, 273 (2001).

K. Nakanishi: Pore structure control of silica gels based on phase separation. J. Porous Mater. 4, 67 (1997).

R. Takahashi, S. Sato, T. Sodesawa, T. Goto, K. Matsutani, and N. Mikami: Bending strength of silica gel with bimodal pores: Effect of variation in mesopore structure. Mater. Res. Bull. 40, 1148 (2005).

P. Sepulveda, J.R. Jones, and L.L. Hench: Bioactive sol-gel foams for tissue repair. J. Biomed. Mater. Res. 59, 340 (2002).

J.R. Jones, O. Tsigkou, E.E. Coates, M.M. Stevens, J.M. Polak, and L.L. Hench: Extracellular-matrix formation and mineralization on a phosphate-free porous bioactive glass scaffold using primary human osteoblast (HOB) cells. Biomaterials 28, 1653 (2007).

H. Maekawa, J. Esquena, S. Bishop, C. Solans, and B.F. Chmelka: Meso/macroporous inorganic oxide monoliths from polymer foams. Adv. Mater. 15, 591 (2003).

W. Liang and C. Russel: Resorbable, porous glass scaffolds by a salt sintering process. J. Mater. Sci. 41, 3787 (2006).

H.S. Yun, S.E. Kim, and Y.T. Hyun: Fabrication of hierarchically porous bioactive glass ceramics. Key Eng. Mater. 361–363, 285 (2008).

C.M. Lofton, C.B. Milz, H. Huang, and W.M. Sigmund: Bicon-tinuous porosity in ceramics utilizing polymer spinodal phase separation. J. Eur. Ceram. Soc. 25, 883 (2005).

A.C. Marques, H. Jain, and R.M. Almeida: Sol-gel derived nano/ macroporous monolithic scaffolds. Phys. Chem. Glasses: Eur. J. Glass Sci. Technol. B 48, 65 (2007).

A.C. Marques, H. Jain, and R.M. Almeida: Nano/macroporous monolithic scaffolds prepared by the sol-gel method. J. Sol-Gel Sci. Technol. 51, 42 (2009).

T. Kokubo and H. Takadama: How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27, 2907 (2006).

R.M. Almeida and A.C. Marques: Characterization of sol-gel materials by infrared spectroscopy, in Handbook of Sol-Gel Science and Technology, edited by S. Sakka (Kluwer Academic Publishers, London, 2005).

M.M. Pereira, A.E. Clark, and L.L. Hench: Calcium phosphate formation on sol-gel-derived bioactive glasses in vitro. J. Biomed. Mater. Res. 28, 693 (1994).

N. Olmo, A.I. Martín, A.J. Salinas, J. Turnay, M. Vallet-Regi, and M.A. Lizarbe: Bioactive sol-gel glasses with and without a HCA layer as substrates for osteoblast cells adhesion and proliferation. Biomaterials 24, 3383 (2003).

J. Zhong and D.C. Greenspan: Processing and properties of sol-gel bioactive glasses. J. Biomed. Mater. Res. 53, 694 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marques, A.C., Almeida, R.M., Thiema, A. et al. Sol-gel-derived glass scaffold with high pore interconnectivity and enhanced bioactivity. Journal of Materials Research 24, 3495–3502 (2009). https://doi.org/10.1557/jmr.2009.0440

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0440