Abstract

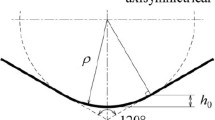

We introduce a novel method to correct for imperfect indenter geometry and frame compliance in instrumented indentation testing with a spherical indenter. Effective radii were measured directly from residual indentation marks at various contact depths (ratio of contact depth to indenter radius between 0.1 and 0.9) and were determined as a function of contact depth. Frame compliance was found to depend on contact depth especially at small indentation depths, which is successfully explained using the concept of an extended frame boundary. Improved representative stress-strain values as well as hardness and elastic modulus were obtained over the entire contact depth.

Similar content being viewed by others

References

S.I. Bulychev, V.P. Alekhin, M.K. Shorshorov, A.P. Ternovskii and G.D. Shnyrev: Determining Young’s modulus from the indentor penetration diagram. Zavod. Lab. 41, 1137 (1975).

M.F. Doerner and W.D. Nix: A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1, 601 (1986).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

A. Gouldstone, N. Chollacoop, M. Dao, J. Li, A.M. Minor and Y.L. Shen: Indentation across size scales and disciplines: Recent developments in experimentation and modeling. Acta Mater. 55, 4015 (2007).

A.C. Fischer-Cripps: A review of analysis methods for sub-micron indentation testing. Vacuum 58, 569 (2000).

N.K. Mukhopadhyay and P. Paufler: Micro- and nanoindentation techniques for mechanical characterisation of materials. Int. Mater. Rev. 51, 209 (2006).

J.S. Field and M.V. Swain: Determining the mechanical-properties of small volumes of material from submicrometer spherical indentations. J. Mater. Res. 10, 101 (1995).

C.A. Schuh: Nanoindentation studies of materials. Mater. Today 9, 32 (2006).

D. Tabor: Hardness of Metals (Clarendon Press, Oxford, 1951).

A. Bolshakov and G.M. Pharr: Influences of pileup on the measurement of mechanical properties by load and depth-sensing indentation techniques. J. Mater. Res. 13, 1049 (1998).

A.C. Fischer-Cripps: Nanoindentation (Springer, New York, 2002).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

Y.T. Cheng and C.M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng., R 44, 91 (2004).

J.Y. Kim, B.W. Lee, D.T. Read and D. Kwon: Influence of tip bluntness on the size-dependent nanoindentation hardness. Scr. Mater. 52, 353 (2005).

J.Y. Kim, S.K. Kang, J.R. Greer and D. Kwon: Evaluating plastic flow properties by characterizing indentation size effect using a sharp indenter. Acta Mater. 56, 3338 (2008).

J.Y. Kim, S.K. Kang, J.J. Lee, J.I. Jang, Y.H. Lee and D. Kwon: Influence of surface-roughness on indentation size effect. Acta Mater. 55, 3555 (2007).

J.H. Ahn and D. Kwon: Derivation of plastic stress-strain relationship from ball indentations: Examination of strain definition and pileup effect. J. Mater. Res. 16, 3170 (2001).

S.H. Kim, B.W. Lee, Y. Choi and D. Kwon: Quantitative determination of contact depth during spherical indentation of metallic materials: A FEM study. Mater. Sci. Eng., A 415, 59 (2006).

J.Y. Kim, K.W. Lee, J.S. Lee and D. Kwon: Determination of tensile properties by instrumented indentation technique: Representative stress and strain approach. Surf. Coat. Technol. 201, 4278 (2006).

E.C. Jeon, J.Y. Kim, M.K. Baik, S.H. Kim, J.S. Park and D. Kwon: Optimum definition of true strain beneath a spherical indenter for deriving indentation flow curves. Mater. Sci. Eng., A 419, 196 (2006).

B. Taljat, T. Zacharia and F. Kosel: New analytical procedure to determine stress-strain curve from spherical indentation data. Int. J. Solids Struct. 35, 4411 (1998).

M. Dao, N. Chollacoop, K.J. Van Vliet, T.A. Venkatesh and S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

N. Chollacoop, M. Dao and S. Suresh: Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713 (2003).

E.G. Herbert, G.M. Pharr, W.C. Oliver, B.N. Lucas and J.L. Hay: On the measurement of stress-strain curves by spherical indentation. Thin Solid Films 398-399, 331 (2001).

S. Jayaraman, G.T. Hahn, W.C. Oliver, C.A. Rubin and P.C. Bastias: Determination of monotonic stress-strain curve of hard materials from ultra-low-load indentation tests. Int. J. Solids Struct. 35, 365 (1998).

Y.T. Cheng and C.M. Cheng: Scaling relationships in conical indentation of elastic perfectly plastic solids. Int. J. Solids Struct. 36, 1231 (1999).

A.E. Giannakopoulos and S. Suresh: Theory of indentation of piezoelectric materials. Scr. Mater. 40, 1191 (1999).

T.A. Venkatesh, K.J. Van Vliet, A.E. Giannakopoulos and S. Suresh: Determination of elasto-plastic properties by instrumented sharp indentation: Guidelines for property extraction. Scr. Mater. 42, 833 (2000).

J.L. Bucaille, S. Stauss, E. Felder and J. Michler: Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 51, 1663 (2003).

K.D. Bouzakis and N. Michailidis: Coating elastic-plastic properties determined by means of nanoindentations and FEM-supported evaluation algorithms. Thin Solid Films 469-470, 227 (2004).

S. Suresh and A.E. Giannakopoulos: A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 465, 755 (1998).

Y.H. Lee and D. Kwon: Estimation of biaxial surface stress by instrumented indentation with sharp indenters. Acta Mater. 52, 1555 (2004).

Y.H. Lee, J.Y. Kim, J.S. Lee, K.H. Kim, J.Y. Koo and D. Kwon: Using the instrumented indentation technique for stress characterization of friction stir-welded API X80 steel. Philos. Mag. 86, 5497 (2006).

J.S. Lee, J.I. Jang, B.W. Lee, Y. Choi, S.G. Lee and D. Kwon: An instrumented indentation technique for estimating fracture toughness of ductile materials: A critical indentation energy model based on continuum damage mechanics. Acta Mater. 54, 1101 (2006).

B.R. Lawn and E.R. Fuller: Equilibrium penny-like cracks in indentation fracture. J. Mater. Sci. 10, 2016 (1975).

B.R. Lawn, A.G. Evans and D.B. Marshall: Effect of residual contact stresses on mirror-flaw-size relations. J. Am. Ceram. Soc. 63, 574 (1980).

T.S. Byun, J.W. Kim and J.H. Hong: A theoretical model for determination of fracture toughness of reactor pressure-vessel steels in the transition region from automated ball indentation test. J. Nucl. Mater. 252, 187 (1998).

J.Y. Kim, S.H. Kim, J.S. Lee, K.W. Lee and D. Kwon: Mechanical characterization of nano-structured materials using nanoindentation. Met. Mater. Int. 12, 219 (2006).

Y.G. Wei, X.Z. Wang and M.H. Zhao: Size effect measurement and characterization in nanoindentation test. J. Mater. Res. 19, 208 (2004).

J.G. Swadener, E.P. George and G.M. Pharr: The correlation of the indentation size effect measured with indenters of various shapes. J. Mech. Phys. Solids 50, 681 (2002).

K.L. Johnson: Contact Mechanics (Cambridge University Press, Cambridge, 1985).

Y.J. Park and G.M. Pharr: Nanoindentation with spherical indenters: Finite element studies of deformation in the elastic-plastic transition regime. Thin Solid Films 447-448, 246 (2004).

W.W. Gerberich, J.C. Nelson, E.T. Lilleodden, P. Anderson and J.T. Wyrobek: Indentation induced dislocation nucleation: The initial yield point. Acta Mater. 44, 3585 (1996).

Y.L. Chiu and A.H.W. Ngan: A TEM investigation on indentation plastic zones in Ni3Al(Cr,B) single crystals. Acta Mater. 50, 1599 (2002).

H. Bei, E.P. George, J.L. Hay and G.M. Pharr: Influence of indenter tip geometry on elastic deformation during nanoindentation. Phys. Rev. Lett. 95, 045501 (2005).

J. Alcalà, A.C. Barone and M. Anglada: The influence of plastic hardening on surface deformation modes around Vickers and spherical indents. Acta Mater. 48, 3451 (2000).

M.A.G. Maneiro and J. Rodríguez: A new consideration on spherical depth-sensing indentation. J. Mater. Lett. 62, 69 (2008).

J. Rodríguez and M.A.G. Maneiro: A procedure to prevent pile up effects on the analysis of spherical indentation data in elastic-plastic materials. Mech. Mater. 39, 987 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, SK., Kim, JY., Kang, I. et al. Effective indenter radius and frame compliance in instrumented indentation testing using a spherical indenter. Journal of Materials Research 24, 2965–2973 (2009). https://doi.org/10.1557/jmr.2009.0358

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0358