Abstract

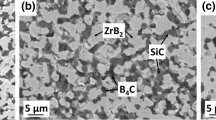

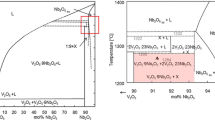

The oxidation resistances of ZrB2 containing SiC, TaB2, and TaSi2 additions of various concentrations were studied using isothermal thermogravimetry at 1200, 1400, and 1500 °C, and specimens were further characterized using x-ray diffraction and electron microscopy. Increasing SiC concentration resulted in thinner glassy surface layers as well as thinner ZrO2-rich underlayers deficient in silica. This silica deficiency was argued to occur by a wicking process of interior-formed borosilicate liquid to the initially-formed borosilicate liquid at the surface. Small (3.32 mol%) concentrations of TaB2 additions were more effective at increasing oxidation resistance than equal additions of TaSi2. The benefit of these additives was related to the formation of a zirconium-tantalum boride solid solution during sintering, which during oxidation, fragmented into fine particles of ZrO2 and TaC. These particles resisted wicking of their liquid/glassy borosilicate encapsulation, which increased overall oxidation resistance. With increasing TaB2 or TaSi2 concentration, oxidation resistance degraded, most egregiously with TaB2 additions. In these cases, zirconia dendrites appeared to grow through the glassy layers, providing conduits for oxygen migration.

Similar content being viewed by others

References

Y. Murata and E.B. Whitney: Densification and wear resistance of ceramic systems: III. Tantalum mononitride-zirconium diboride. Am. Ceram. Soc. Bull. 48 (7), 698 (1969).

Y. Murata: Densification and wear resistance of HfN-ZrB2 compositions. Am. Ceram. Soc. Bull. 52 (3), 255 (1973).

X. Zhang, P. Hu, S. Meng, J. Han, and B. Wang: Microstructure and mechanical properties of ZrB2-based ceramics. Key Eng. Mater. 312, 287 (2006).

W.C. Tripp: Effect of an SiC addition on the oxidation of ZrB2. Am. Ceram. Soc. Bull. 52 (8), 1606 (1973).

M.M. Opeka, I.G. Talmy, E.J. Wuchina, J.A. Zaykosi, and S.J. Causey: Mechanical, thermal, and oxidation properties of refractory hafnium and zirconium compounds. J. Eur. Ceram. Soc. 19, 2405 (1999).

A.R. Rezaie, W.G. Fahrenholtz, and G.E. Hilmas: Oxidation of zirconium diboride-silicon carbide at 1500 °C in a low partial pressure of oxygen. J. Am. Ceram. Soc. 89 (10), 3240 (2006).

A.K. Varshneya: Fundamentals of Inorganic Glasses (Academic Press, New York, 1994).

E.J. Opila and M.C. Halbig: Oxidation of ZrB2-SiC. Elec. Chem. Soc. Proc. 12, 221 (2002).

A. Rezaie, W.G. Fahrenholtz, and G.E. Hilmas: Evolution of structure during the oxidation of zirconium diboride-silicon carbide in air up to 1500 °C. J. Eur. Ceram. Soc. 27, 2495 (2007).

M. Opeka, I. Talmy, and J. Zayk:oski: Oxidation-based materials selection for 2000 °C+ hypersonic aerosurfaces: Theoretical considerations and historical experience. J. Mater. Sci. 39, 5887 (2004).

J. Han, P. Hu, X. Zhang, and S. Meng: Oxidation behavior of zirconium diboride-silicon carbide at 1800 °C. Scr. Mater. 57, 825 (2007).

S.N. Karlsdottir, J.W. Halloran, and A.N. Grundy: Zirconia transport by liquid convection during oxidation of zirconium diboride-silicon carbide. J. Am. Ceram. Soc. 91 (1), 272 (2008).

I.G. Talmy, J.A. Zaykoski, M.M. Opeka, and S. Dallek: Oxidation of ZrB2 ceramics modified with SiC and group IV–VI transition metal diborides. Elec. Chem. Soc. Proc. 12, 144 (2001).

W. Vogel: Glass Chemistry, 2nd ed. (Springer-Verlag, New York, 1994).

E. Opila, S. Levine, and J. Lorincz: Oxidation of ZrB2- and HfB2-based ultra-high temperature ceramics: Effect of Ta additions. J. Mater. Sci. 39, 5969 (2004).

I.G. Talmy, J.A. Zaykoski, M.M. Opeka, and A.H. Smith: Properties of ceramics in the system ZrB2-Ta5Si3. J. Mater. Res. 21 (10), 2593 (2006).

S. R. Levine, and E. J. Opila: Tantalum addition to zirconium diboride for improved oxidation resistance. NASA/TM–2003–212483.

S.C. Zhang, G.E. Hilmas, and W.G. Fahrenholtz: Improved oxidation resistance of zirconium diboride by tungsten carbide additions. J. Am. Ceram. Soc. 91, 3530 (2008).

X-H. Zhang, P. Hu, J-C. Han, L. Xu and S-H. Meng: The addition of lanthanum hexaboride to zirconium diboride for improved oxidation resistance. Scr. Mater. 57 (1) 36–39 (2007).

F. Peng and R.F. Speyer: Oxidation resistance of fully dense ZrB2 with SiC, TaB2, and TaSi2 additives. J. Am. Ceram. Soc. 91 (5), 1489 (2008).

W.E. Lee and W.M. Rainforth: Ceramic Microstructures, Property Control by Processing (Chapman and Hall, London, 1994).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, F., Berta, Y. & Speyer, R.F. Effect of SiC, TaB2 and TaSi2 additives on the isothermal oxidation resistance of fully dense zirconium diboride. Journal of Materials Research 24, 1855–1867 (2009). https://doi.org/10.1557/jmr.2009.0216

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0216