Abstract

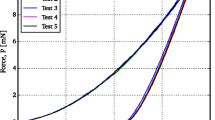

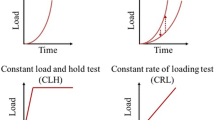

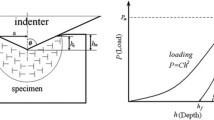

Recent computational parametric studies have developed reverse algorithms to extract material properties of elastoplastic materials using experimental sharp nanoindentation. These methods used reduced modulus in their parameters to include the effect of indenter compliance. To investigate the validity of using reduced modulus, we conducted experimental indentation of a couple of representative cases for elastoplastic metals with a diamond and a sapphire Berkovich tip. Then, we performed a finite element study for sharp indentation of the same material systems. Both computational and experimental results indicate that the use of reduced modulus is invalid to describe indentation loading response for elastoplastic materials in a certain material regime. Our results show that indenter compliance is overestimated by the previous predictions using reduced modulus. This overestimation leads to underestimation of indenter curvature and causes error in extracting material properties by reverse algorithms.

Similar content being viewed by others

References

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

M.M. Chaudhri: A note on a common mistake in the analysis of nanoindentation data. J. Mater. Res. 16, 336 (2001).

Y.Y. Lim and M.M. Chaudhri: Indentation of elastic solids with rigid cones. Philos. Mag. 84, 2877 (2004).

Y.P. Cao, M. Dao, and J. Lu: A precise correcting method for the study of the superhard material using nanoindentation tests. J. Mater. Res. 22, 1255 (2007).

J.L. Bucaille, S. Stauss, E. Felder, and J. Michler: Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 51, 1663 (2003).

N. Chollacoop, M. Dao, and S. Suresh: Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713 (2003).

Y.P. Cao and J. Lu: A new scheme for computational modeling of conical indentation in plastically graded materials., J. Mater. Res. 19, 1703 (2004).

Y.P. Cao, X.Q. Qian, J. Lu, and Z.H. Yao: An energy-based method to extract plastic properties of metal materials from conical indentation tests., J. Mater. Res. 20, 1194 (2005).

M. Dao, N. Chollacoop, K.J. Van Vliet, T.A. Venkatesh, and S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

N. Huber, E. Tyulyukovskiy, and O. Kraft: On the analysis of the stress-strain behaviour of thin metal films on substrates using nanoindentation. Philos. Mag. 86, 5505 (2006).

L.G. Wang and S.I. Rokhlin: Universal scaling functions for continuous stiffness nanoindentation with sharp indenters. Int. J. Solids Struct. 42, 3807 (2005).

Y.P. Cao, X.Q. Qian, and N. Huber: Spherical indentation into elastoplastic materials: Indentation-response based definitions of the representative strain. Mater. Sci. Emg. A, 454, 1 (2007).

M. Watanabe, C. Mercer, C.G. Levi, and A.G. Evans: A probe for the high temperature deformation of thermal barrier oxides. Acta Mater. 52, 1479 (2004).

A. Sawant and S. Tin: High temperature nanoindentation of a Re-bearing single crystal Ni-base superalloy. J. Biomech. 58, 275 (2008).

P. Neumann: Simplification of crystallographic calculations in hexagonal lattices through consequent application of 4-axis hexagonal coordinate system. Phys. Status Solidi 17, K71 (1966).

A-A.F. Tavassoli, J-W. Rensman, M. Schirra, and K. Shiba: Materials design data for reduced activation martensitic steel type F82H. Fusion Em. Des. 61–62, 617 (2002).

Matweb. www.matweb.com. (Automation Creation, Inc., 2008).

J. Aktaa: Private communication. (2008).

I.S. Choi, M. Dao, and S. Suresh: Mechanics of indentation of plastically graded materials—I: Analys is. J. Mech. Phys. Solids 56, 157 (2008).

I.S. Choi, A.J. Detor, R. Schwaiger, M. Dao, C.A. Schuh, and S. Suresh: Mechanics of indentation of plastically graded materials—II: Experiments on nanocrystalline alloys with grain size gradients. J. Mech. Phys. Solids 56, 172 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, Is., Kraft, O. & Schwaiger, R. Validity of the reduced modulus concept to describe indentation loading response for elastoplastic materials with sharp indenters. Journal of Materials Research 24, 998–1006 (2009). https://doi.org/10.1557/jmr.2009.0120

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0120