Abstract

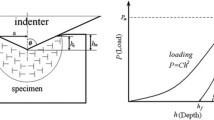

A linear relationship between the ratio of elastic work to the total indentation work and hardness to reduced modulus, i.e., We/Wt = λ H/Er, has been derived analytically and numerically in a number of studies and has been widely accepted. However, the scaling relationship between We/Wt and H/Er has recently been questioned, and it was found that λ is actually not a constant but is related to material properties. In this study, a new relationship between We/Wt and H/Er has been derived, which shows excellent agreement with numerical simulation and experimental results. We also propose a method for obtaining the elastic modulus and hardness of a material without invoking the commonly used Oliver and Pharr method. Furthermore, it is demonstrated that this method is less sensitive to tip imperfections than the Oliver and Pharr approach is.

Similar content being viewed by others

References

N.A. Stilwell and D. Tabor: Elastic recovery of conical indentations. Proc. Phys. Soc. London 78, 169 (1961).

Y-T. Cheng, Z. Li, and C-M. Cheng: Scaling relationships for indentation measurements. Philos. Mag. A 82, 1821 (2002).

Y-T. Cheng and C-M. Cheng: Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 73, 614 (1998).

A.E. Giannakopoulos and S. Suresh: Determination of elastoplastic properties by instrumented sharp indentation. Scr. Mater. 40, 1191 (1999).

D. Ma, W. Chung, J. Liu, and J. He: Determination of Young’s modulus by nanoindentation. Sci. China, Ser. E 47, 398 (2004).

J. Malzbender: Comment on the determination of mechanical properties from the energy dissipated during indentation. J. Mater. Res. 20, 1090 (2005).

W.C. Oliver: Alternative technique for analyzing instrumented indentation data. J. Mater. Res. 16, 3202 (2001).

S.V. Hainsworth, H.W. Chandler, and T.F. Page: Analysis of nanoindentation load-displacement loading curves. J. Mater. Res. 11, 1987 (1996).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

G.M. Pharr and A. Bolshakov: Understanding nanoindentation unloading curves. J. Mater. Res. 17, 2660 (2002).

Y-T. Cheng and C-M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng., R 44, 91 (2004).

I.N. Sneddon: The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

J.C. Hay, A. Bolshakov, and G.M. Pharr: A critical examination of the fundamental relations used in the analysis of nanoindentation. J. Mater. Res. 14, 2296 (1999).

J. Alkorta, J.M. Martínez-Esnaola, and J. Gil Sevillano: Comments on “Comment on the determination of mechanical properties from the energy dissipated during indentation” by J. Malzbender [J. Mater. Res. 20, 1090 (2005)]. J. Mater. Res. 21, 302 (2006).

Y. Choi, H.S. Lee, and D. Kwon: Analysis of sharp-tip-indentation load-displacement curve for contact area determination taking into account pile-up and sink-in effects. J. Mater. Res. 19, 3307 (2004).

M. Sakai: Simultaneous estimate of elastic/plastic parameters in depth-sensing indentation tests. Scr. Mater. 51, 391 (2004).

V. Marx and H. Balke: A critical investigation of the unloading behavior of sharp indentation. Acta Mater. 45, 3791 (1997).

J. Malzbender and G. de With: Indentation load-displacement curve, plastic deformation and energy. J. Mater. Res. 17, 502 (2002).

J. Chen and S.J. Bull: A critical examination of the relationship between plastic deformation zone size and Young’s modulus to hardness ratio in indentation testing. J. Mater. Res. 21, 2617 (2006).

M. Li, W. Chen, N. Liang, and L. Wang: A numerical study of indentation using indenters of different geometry. J. Mater. Res. 19, 73 (2004).

S. Soare: Design of a rotating sensor for stress measurement in metallization. Ph.D. Thesis, University of Newcastle upon Tyne, UK, 2004.

S. Jayaraman, G.T. Hahn, W.C. Oliver, C.A. Rubin, and P.C. Bastias: Determination of monotonic stress-strain curve of hard materials from ultra-low-load indentation tests. Int. J. Solids Struct. 35, 365 (1998).

T.A. Venkatesh, K.J. Van Vleit, A.E. Ginnakopoulos, and S. Suresh: Determination of elasto-plastic properties by instrumented sharp indentation: Guidelines for property extraction. Scr. Mater. 42, 833 (2000).

J.F. Palacio: Mechanical properties of high performance fuller-ene-like CNx coatings assessed by nanoindentation. Ph.D. Thesis, University of Newcastle upon Tyne, UK, 2006.

Y.T. Cheng and C.M. Cheng: Further analysis of indentation loading curves: Effects of tip rounding on mechanical property measurements. J. Mater. Res. 13, 1059 (1998).

J. Chen and S.J. Bull: On the relationship between plastic zone radius and maximum depth during nanoindentation. Surf. Coat. Technol. 201, 4289 (2006).

H. Bei, E.P. George, J.L. Hay, and G.M. Pharr: Influence of indenter tip geometry on elastic deformation during nanoindentation. Phys. Rev. Lett. 95(045501), 1 (2005).

J. Chen and S.J. Bull: Multicycling nanoindentation study on thin optical coatings on glass. J. Phys. D: Appl. Phys. 41, 074009 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Bull, S.J. Relation between the ratio of elastic work to the total work of indentation and the ratio of hardness to Young’s modulus for a perfect conical tip. Journal of Materials Research 24, 590–598 (2009). https://doi.org/10.1557/jmr.2009.0086

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0086