Abstract

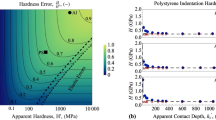

A correction to the nanoindentation technique taking into account the elastic recovery at extremely shallow contact depths was proposed. Using a high-sensitivity nanoindentation system with a sharp indenting tip, the magnitude of the elastic recovery could be obtained directly from very low-force load–unload curves, which was then used to correct the contact area used for hardness measurements. Nanoindentation experiments were performed on a standard fused quartz sample and, compared to standard nanoindentation techniques, the proposed method was found to be more accurate at ultrashallow indenting depths of <3 nm.

Similar content being viewed by others

References

H. Buckle: The Science of Hardness Testing and Its Research Applications American Society for Metals Metals Park, OH 1973 453

M. Lichinchi, C. Lenardi, J. Haugt K. Vitali: Simulation of Berkovich nanoindentation experiments on thin films using finite element method. Thin Solid Films 312, 240 1998

Z. Xu D. Rowcliffe: Nanoindentation on diamond-like carbon and alumina coatings. Surf. Coat. Technol. 161, 44 2002

C-D. Yeo, A.A. Polycarpou, J.D. Kiely Y-T. Hsia: Nanomechanical properties of sub-10 nm carbon film overcoats using the nanoindentation technique. J. Mater. Res. 22, 141 2007

W.C. Oliver G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 1992

M. Kohzaki, A. Matsumuro, T. Hayashi, M. Muramatsu K. Yamaguchi: Preparation of carbon nitride thin films by ion-beam-assisted deposition and their mechanical properties. Thin Solid Films 308–309, 239 1997

T.W. Scharf, H. Deng J.A. Barnard: Nanowear/nanomechanical testing and the role of stress in sputtered CNx overcoats. J. Appl. Phys. 81(8), 5393 1997

I.N. Sneddon: The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 1965

P. Lemoine, J.F. Zhao, J.P. Quinn, J.A. McLaughlin P. Maguire: Hardness measurements at shallow depths on ultra-thin amorphous carbon films deposited onto silicon and Al2O3-TiC substrates. Thin Solid Films 379, 166 2000

N.A. Stilwell D. Tabor Elastic recovery of conical indentation. Phys. Proc. Soc., 78, 169 (1961)

Y. Cheng C. Cheng: Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 73(5), 614 1998

Y. Cheng C. Cheng: Scaling approach to conical indentation in elastic-plastic solids with work hardening. J. Appl. Phys. 84, 1284 1998

J.R. Tuck, A.M. Korsunsky, S.J. Bull R.I. Davison: On the application of the work-of-indentation approach to depth-sensing indentation experiments in coated systems. Surf. Coat. Technol. 137, 217 2001

A.E. Giannakopoulos S. Suresh: Determination of elastoplastic properties by instrumented sharp indentation. Scripta Mater. 40(10), 1191 1999

N. Yu, W.A. Bonin A.A. Polycarpou: High-resolution capacitive load-displacement transducer and its application in nanoindentation and adhesion force measurements. Rev. Sci. Instrum. 76, 045109 2005

N. Yu A.A. Polycarpou: Use of the focused ion beam technique to produce a sharp spherical diamond indenter for sub-10 nm nanoindentation measurements. J. Vac. Sci. Technol., B 22, 668 2004

Acknowledgments

This research was supported by the National Science Foundation under Grant No. CAREER CMS-0239232. The nanoindentation measurements were performed at the Center for Microanalysis of Materials at the University of Illinois, which is supported by the United States Department of Energy under Grant No. DEFG02-96-366 ER45439.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeo, CD., Polycarpou, A.A. A correction to the nanoindentation technique for ultrashallow indenting depths. Journal of Materials Research 22, 2359–2362 (2007). https://doi.org/10.1557/jmr.2007.0300

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0300