Abstract

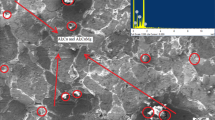

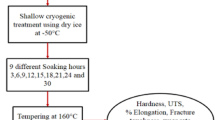

Structural ceramics are considered as potential candidate materials for use in hybrid bearings in rocket turbopumps, operated under high stress in cryogenic environment. The friction and wear-related surface failure is considered as one of the critical factors in selecting the materials for cryo-turbopumps of Space Shuttle Main Engine (SSME). To obtain fundamental understanding of the tribological properties of ceramics in cryogenic environment, a very first set of sliding wear tests were carried out on self-mated Al2O3, a model brittle ceramic material, in liquid nitrogen (LN2) under varying load (2–10 N) and high rotational speed of 2550 rpm, using a newly designed cryogenic tribometer. The present research attempts to answer some important questions: (i) What would be the influence of LN2 on frictional and fracture behavior at sliding contacts? (ii) How does the material removal process occur in LN2 environment? Our experimental results reveal that self-mated alumina exhibits low steady-state coefficient of friction ∼0.13–0.18 and suffers from high wear rate (10−5 mm3/Nm) under the selected testing conditions. The novelty of the present work also lies in presenting some interesting results, for the first time, concerning the deformation and fracture of alumina at cryogenic temperature under high speed sliding conditions. Detailed scanning electronic microscope observation of the worn surfaces indicates that severe damage of both ball and flat occurs in cryogenic environment by transgranular and intergranular fracture. The observed wear behavior is explained in terms of thermal heat dissipation and brittle fracture of alumina in LN2.

Similar content being viewed by others

References

M. Nosaka, M. Kikuchi, M. Oke, N. Kawai: Tribo-characteristics of cryogenic hybrid ceramic ball bearings for rocket turbopumps: Bearing wear and transfer film. Tribol. Trans. 42, 106 (1999).

M. Nosaka, S. Takada, M. Kikuchi, T. Sudo, M. Yoshida: Ultra-high speed performance of ball bearings and annular seals in liquid hydrogen at up to 3 million DN (120,000 rpm). Tribol. Trans. 47, 43 (2004).

T. Gradt, T. Schneider, W. Hübner, H. Börner: Friction and wear at low temperatures. Int. J. Hydrogen Energy 23, 397 (1998).

I.V. Kragelsky, M.N. Dobychin, V.S. Kombalow: Friction and Wear (Permagon Press, Oxford, UK, 1982), p. 224.

Y.Le. Ostrovskaya, T.P. Yukhno, G.D. Gamulya, Y. Vvedenskij. V., V.I. Kuleba: Low temperature tribology at the B. Verkin institute for low temperature physics and engineering (historical review). Tribol. Int. 34, 265 (2001).

W. Hübner: Phase transformations in austenitic stainless steels during low temperature tribological stressing. Tribol. Int. 34, 231 (2001).

W. Hübner, T. Gradt, T. Schneider, H. Börner: Tribological behaviour of materials at cryogenic temperatures. Wear 216, 150 (1998).

P. Andersson: A study on dry and poorly lubricated alumina journal bearings. Finn. J. Tribol. 1, 97 (1993).

D. Rani Amutha, Y. Yoshizawa, H. Hyuga, K. Hirao, Y. Yamauchi: Tribological behavior of ceramic materials (Si3N4, SiC and Al2O3) in aqueous medium. J. Eur. Ceram. Soc. 24, 3279 (2004).

A. Ravikiran: Influence of apparent pressure on wear behavior of self-mated alumina. J. Am. Ceram. Soc. 83, 1302 (2000).

J.D.O. Barceinas-Sánchez, W. Rainforth M.: On the role of plastic deformation during the mild wear of alumina. Acta Mater. 46, 6475 (1998).

M.C. Jeng, L.Y. Yan: Environmental effects on wear behaviour of alumina. Wear 161, 111 (1993).

S.M. Hsu, M.C. Shen: Ceramic wear maps. Wear 200, 154 (1996).

Y. Wang, S.M. Hsu: The effects of operating parameters and environment on the wear and wear transition of alumina. Wear 195, 90 (1996).

F. Xiong, R.R. Manory, L. Ward, M. Terheci, S. Lathabai: Effect of grain size and test configuration on the wear behavior of alumina. J. Am. Ceram. Soc. 80, 1310 (1997).

K. Komvopoulos, H. Li: The effect of tribofilm formation and humidity on the friction and wear properties of ceramic materials. J. Tribol. 114, 131 (1992).

T. Hisakado: Wear mechanism of ceramics and surface topography. J. Tribol. 108, 9 (1986).

Y.S. Wang, S.M. Hsu, R.G. Munro: Ceramics wear maps: Alumina. Lubr. Eng. 47, 63 (1991).

G.R. Anstis, P. Chantikul, B.R. Lawn, D.B. Marshall: A critical evaluation of indentation techniques for measuring fracture toughness: I. Direct crack measurements. J. Am. Ceram. Soc. 64, 533 (1981).

B. Subramonian, B. Basu: Development of a high-speed cryogenic tribometer: Design concept and experimental results. Mater. Sci. Eng. A 415, 72 (2006).

Japanese industrial standards committee: Testing methods for wear resistance of high performance of high performance ceramics by ball-on-disk method, JIS R 1613 (Japanese Standard Association, Tokyo, Japan, 1993).

R.S. Gates, S.M. Hsu, E.E. Kalus: Tribochemical mechanism of alumina with water. Tribol. Trans. 32, 357 (1989).

J. Takadoum: Tribological behavior of alumina sliding on several kinds of materials. Wear 170, 285 (1993).

P. Andersson: Water lubricated pin-on-disk tests with ceramics. Wear 154, 37 (1992).

A. Blomberg, M. Olsson, S. Hogmark: Wear mechanisms and tribo mapping of Al2O3 and SiC in dry sliding. Wear 171, 77 (1994).

W.D. Kingery, H.K. Bowen, and D.R. Uhlmann: Introduction to Ceramics, 2nd ed. (Wiley Interscience, New York, 2004), Chap. 12, pp. 615, 616, 619, 797.

D.A. Wigley: Materials for Low Temperature Use, Engineering Design Guides, Vol. 26 (1978), pp. 32, 33.

S.M. Hsu, M. Shen: Wear prediction of ceramics. Wear 256, 867 (2004).

A.H. Heuer: Deformation twinning in corundum Philos. Mag. 142, 379 (1966).

J. Congleton, N.J. Petch: Crack branching. Philos. Mag. 142, 749 (1967).

R.W. Davidge: Mechanical Behavior of Ceramics (Cambridge University Press, Cambridge, UK, 1979), p. 12.

K. Ota: Elastic modulus and the measurement of structural ceramics at cryogenic temperatures. Cryogenics 35, 735 (1995).

B. Bhushan: Principles and Applications of Tribology (Wiley Interscience, New York, 1999), p. 447.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanna, R., Basu, B. Low friction and severe wear of alumina in cryogenic environment: A first report. Journal of Materials Research 21, 832–843 (2006). https://doi.org/10.1557/jmr.2006.0104

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0104