Abstract

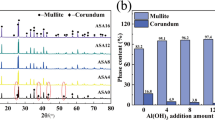

Secondary mullite has been formed in 60 wt% kaolin–40 wt% Al2O3 ceramics by solution-precipitation in the glassy phase in contact with Al2O3 particle, showing a plate-like morphology, at temperatures above 1673 K. The lattice constant modification of secondary mullite has been determined: the lattice parameters of orthorhombic structure of a, b, and c axes decrease from 8.653, 8.770, and 3.167 Å to 7.958, 8.064, and 2.926 Å, respectively. The Al2O3 content in the secondary mullite crystals increases from 59.69 to 70.41 wt% when the grain width increases from 15 to 40 nm. Both the formation of secondary mullite and its grain growth are intimately related to the presence of the glassy phase originated from impurity (K2O) in the kaolin. Their locations as well as their chemical composition of mullite grains, Al2O3 grains, and glassy phase are provided by the meticulous experiments using high-resolution transmission electron microscopy, selected-area electron diffraction, and energy dispersive spectroscopy techniques.

Similar content being viewed by others

References

I.A. Aksay, D.M. Dabbs, and M. Sarikaya, J. Am. Ceram. Soc. 74, 2343 (1991).

K.C. Liu, G. Thomas, A. Caballero, J.S. Moya, and S.D. Aza, Acta. Metall. Mater. 42, 489 (1994).

T. Takei, Y. Kameshima, A. Yasumori, and K. Okada, J. Am. Ceram. Soc. 82, 2876 (1999).

M.A. Sainz, F.J. Serrano, J.M. Amigo, J. Bastida, and A. Caballero, J. Eur. Ceram. Soc. 20, 403 (2000).

C.Y. Chen, G.S. Lan, and W.H. Tuan, J. Eur. Ceram. Soc. 20, 2519 (2000).

H.J. Kleebe, F. Siegelin, T. Straubinger, and G. Ziegler, J. Eur. Ceram. Soc. 21, 2521 (2001).

A. Gualtieri, M. Bellotto, G Artioli, and S.M. Clark, Phys. Chem. Minerals 22, 215 (1995).

Y.F. Chen, M.C. Wang, and M.H. Hon, J. Mater. Res. 18, 1355 (2003).

Y.F. Chen, M.C. Wang, and M.H. Hon, J. Ceram. Soc. Jpn. 111, 537 (2003).

Y.F. Chen, Y.H. Chang, M.C. Wang, and M.H. Hon, J. Mat. Sci. Eng. A, (in press).

O. Matsuda, T. Watari, T. Torikai, Y. Yamasaki, and H. Katsuki, J. Ceram. Soc. Jpn. 100, 719 (1992).

K. Hamano, H. Nakajima, F. Okuda, and M. Konuma, J. Ceram. Soc. Jpn. 102, 80 (1994).

Y.F. Chen, M.C. Wang, and M.H. Hon, Scripta Mater., (in press).

Y.F. Chen, M.C. Wang, and M.H. Hon, J. Eur. Ceram. Soc. (2003, in press).

M. Schmücker, W. Albers, and H. Schneider, J. Eur. Ceram. Soc. 14, 511 (1994).

E.F. Osborn and A. Muan, “Phase Equilibrium Diagrams of Oxide Systems”, Plate 5, American Ceramic Society and Edward Orton, Jr. (Ceramic Foundation, New York, 1960).

S.H. Risbud and J.A. Pask, J. Mater. Sci. 13, 2449 (1978).

C.W. Burnham, Carnegie Inst. 63, 227 (1964).

S.M. Johnson and J.A. Pask, Ceram. Bull. 61, 838 (1982).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, YF., Wang, MC. & Hon, MH. Secondary Mullite Formation in Kaolin–Al2O3 Ceramics. Journal of Materials Research 19, 806–814 (2004). https://doi.org/10.1557/jmr.2004.19.3.806

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2004.19.3.806