Abstract

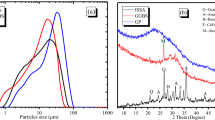

Fluidized Bed Steam Reforming (FBSR) is being considered as a potential technology for the immobilization of a wide variety of high sodium low activity wastes (LAW) such as those existing at the Hanford site, at the Idaho National Laboratory (INL), and the Savannah River Site (SRS). The addition of clay, charcoal, and a catalyst as co-reactants with the waste denitrates the aqueous wastes and forms a granular mineral waste form that can subsequently be made into a monolith for disposal if necessary. The waste form produced is a multiphase mineral assemblage of Na-Al-Si (NAS) feldspathoid minerals with cage and ring structures and iron bearing spinel minerals. The mineralization occurs at moderate temperatures between 650-750°C in the presence of superheated steam. The cage and ring structured feldspathoid minerals atomically bond radionuclides like Tc-99 and Cs-137 and anions such as SO4, I, F, and Cl. The spinel minerals stabilize Resource Conservation and Recovery Act (RCRA) hazardous species such as Cr and Ni. Granular mineral waste forms were made from (1) a basic Hanford Envelope A low-activity waste (LAW) simulant and (2) an acidic INL simulant commonly referred to as sodium-bearing waste (SBW) in pilot scale facilities at the Science Applications International Corporation (SAIC) Science and Technology Applications Research (STAR) facility in Idaho Falls, ID. The FBSR waste forms were characterized and the durability tested via ASTM C1285 (Product Consistency Test), the Environmental Protection Agency (EPA) Toxic Characteristic Leaching Procedure (TCLP), and the Single Pass Flow Through (SPFT) test. The results of the SPFT testing and the activation energies for dissolution are discussed in this study.

Similar content being viewed by others

References

J.B. Mason, T.W. Oliver, M.P. Carson, G.M. Hill, G.M. WM 99 Conference (1999).

J.B. Mason, J. McKibben, K. Ryan, D. Schmoker, J. WM 03 Conference (2003).

C.M. Jantzen, U.S. DOE Report WSRC-TR-2002-00317 (2002).

C.M. Jantzen, Ceramic Transactions 155, 319–329 (2004).

B.P. McGrail, H.T. Schaef, P.F. Martin, D.H. Bacon, E.A. Rodriguez, D.E. McCready, A.N. Primak, and R.D. Orr, U.S. DOE Report PNWD-3288 (2003).

A.L. Olson, N.R. Soelberg, D.W. Marshall, G.L. Anderson, U.S. DOE Report INEEL/EXT-04-02492; (2004).

N.R. Soleberg, D.W. Marshall, S.O. Bates, D.D. Taylor, U.S. DOE Report INEEL/EXT-04-01493 (2004).

A.L. Olson, N.R. Soelberg, D.W. Marshall, G.L. Anderson, U.S. DOE Report INEEL/EXT-04-02564; (2004).

S.D. Rassat, L.A. Mahoney, R.L. Russell, S.A. Bryan, and R.L. Sell, U.S. DOE Report PNNL-14194-Rev. 1 (2003).

J.M. Pareizs, C.M. Jantzen, T.H. Lorier, U.S. DOE Report WSRC-TR-2005-00102 (2005).

C.M. Jantzen, J.M. Pareizs, T.H. Lorier, and J.M. Marra, Ceramic Trans., 176, 121–137 (2006).

B.P. McGrail, U.S. DOE Report PNNL-14414 (2003).

T.H. Lorier, J.M. Pareizs, and C.M. Jantzen, U.S. DOE Report, WSRC-TR-2005-00124 (2005).

C.M. Jantzen, WM 06 Conference (2006).

K.G. Knauss, W.L. Bourcier, K.D. McKeegan, C.I. Merzbacher, S.N. Nguyen, R.J. Ryerson, D.K. Smith, H.C. Weed, and L. Newton, L. Sci. Basis Nucl. Waste Mgt., XIII, Mat. Res. Soc., Pittsburgh, PA, 371–381 (1990).

C.M. Jantzen, D.R. Clarke, P.E.D. Morgan, P.E.D. and A.B. Harker, J. Am. Ceram. Soc. 65[6], 292–300 (1982).

E.S. Dana, “A Textbook of Mineralogy,” John Wiley & Sons, Inc., New York, 851pp (1932).

W. A. Deer, R. A. Howie, and J. Zussman, “Rock-Forming Minerals,” Vol IV, John Wiley & Sons, Inc., New York, 435pp. (1963).

D.G. Brookins, “Geochemical Aspects of Radioactive Waste Disposal,” Springer-Verlag, New York, 347pp. (1984).

S.V. Mattigod, B. P. McGrail, D.E. McCready, L.Q. Wang, K.E. Parker, and J.S. Young, Submitted to Microsporous and Mesoporous Materials (2006).

M.P. Tole, A.C. Lasaga, C. Pantano, W.B. White, Geochimica Cosmochimica Acta, 50, 379–392 (1985).

J.P. Hamilton, S.L. Brantley, C.G. Pantano, L.J. Criscenti, J.D. Kubiki, Geochimica Cosmochimica Acta, 65 [21], 3683–3702 (2001).

T.H. Lorier, C.M. Jantzen, J.C. Marra, and J.M. Pareizs, Ceramic Trans. V. 176, 111–119 (2006).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jantzen, C.M., Lorier, T.H., Pareizs, J.M. et al. Fluidized Bed Steam Reformed (FBSR) Mineral Waste Forms: Characterization and Durability Testing. MRS Online Proceedings Library 985, 1004 (2006). https://doi.org/10.1557/PROC-985-0985-NN10-04

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/PROC-985-0985-NN10-04