Abstract

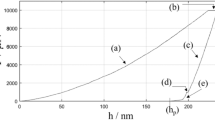

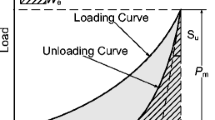

We evaluate Vickers hardness and true instrumented indentation test (IIT) hardness of 24 metals over a wide range of mechanical properties using just IIT parameters by taking into account the real contact morphology beneath the Vickers indenter. Correlating the conventional Vickers hardness, indentation contact morphology, and IIT parameters for the 24 metals reveals relationships between contact depths and apparent material properties. We report the conventional Vickers and true IIT hardnesses measured only from IIT contact depths; these agree well with directly measured hardnesses within ±6% for Vickers hardness and ±10% for true IIT hardness.

Similar content being viewed by others

References

S.I. Bulychev, V.P. Alekhin, M.K. Shorshorov, A.P. Ternovskii, G.D. Shnyrev Determining Young’s modulus from the indentor penetration diagram. Zavod. Lab. 41, 1137 (1975)

M.F. Doerner, W.D. Nix A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1, 601 (1986)

W.C. Oliver, G.M. Pharr An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992)

A. Gouldstone, N. Chollacoop, M. Dao, J. Li, A.M. Minor, Y.L. Shen Indentation across size scales and disciplines: Recent developments in experimentation and modeling. Acta Mater. 55, 4015 (2007)

A.C. Fischer-Cripps A review of analysis methods for sub-micron indentation testing. Vacuum 58, 569 (2000)

N.K. Mukhopadhyay, P. Paufler Micro- and nanoindentation techniques for mechanical characterisation of materials. Int. Mater. Rev. 51, 209 (2006)

J.S. Field, M.V. Swain Determining the mechanical-properties of small volumes of material from submicrometer spherical indentations. J. Mater. Res. 10, 101 (1995)

C.A. Schuh Nanoindentation studies of materials. Mater. Today 9, 32 (2006)

D. Tabor Hardness of Metals (Clarendon Press, Oxford 1951)

A. Bolshakov, G.M. Pharr Influences of pileup on the measurement of mechanical properties by load and depth-sensing indentation techniques. J. Mater. Res. 13, 1049 (1998)

A.C. Fischer-Cripps Nanoindentation (Springer, New York 2002)

W.C. Oliver, G.M. Pharr Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004)

Y.T. Cheng, C.M. Cheng Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng., R 44, 91 (2004)

J.Y. Kim, S.K. Kang, J.R. Greer, D. Kwon Evaluating plastic flow properties by characterizing indentation size effect using a sharp indenter. Acta Mater. 56, 3338 (2008)

J.Y. Kim, S.K. Kang, J.J. Lee, J.I. Jang, Y.H. Lee, D. Kwon Influence of surface-roughness on indentation size effect. Acta Mater. 55, 3555 (2007)

J.H. Ahn, D. Kwon Derivation of plastic stress–strain relationship from ball indentations: Examination of strain definition and pileup effect. J. Mater. Res. 16, 3170 (2001)

S.H. Kim, B.W. Lee, Y. Choi, D. Kwon Quantitative determination of contact depth during spherical indentation of metallic materials—A FEM study. Mater. Sci. Eng., A 415, 59 (2006)

J.Y. Kim, K.W. Lee, J.S. Lee, D. Kwon Determination of tensile properties by instrumented indentation technique: Representative stress and strain approach. Surf. Coat. Technol. 201, 4278 (2006)

E.C. Jeon, J.Y. Kim, M.K. Baik, S.H. Kim, J.S. Park, D. Kwon Optimum definition of true strain beneath a spherical indenter for deriving indentation flow curves. Mater. Sci. Eng., A 419, 196 (2006)

B. Taljat, T. Zacharia, F. Kosel New analytical procedure to determine stress–strain curve from spherical indentation data. Int. J. Solids Struct. 35, 4411 (1998)

M. Dao, N. Chollacoop, Van K.J. Vliet, T.A. Venkatesh, S. Suresh Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001)

N. Chollacoop, M. Dao, S. Suresh Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713 (2003)

E.G. Herbert, G.M. Pharr, W.C. Oliver, B.N. Lucas, J.L. Hay On the measurement of stress–strain curves by spherical indentation. Thin Solid Films 398–399, 331 (2001)

S. Jayaraman, G.T. Hahn, W.C. Oliver, C.A. Rubin, P.C. Bastias Determination of monotonic stress–strain curve of hard materials from ultra-low-load indentation tests. Int. J. Solids Struct. 35, 365 (1998)

Y.T. Cheng, C.M. Cheng Scaling relationships in conical indentation of elastic perfectly plastic solids. Int. J. Solids Struct. 36, 1231 (1999)

A.E. Giannakipoulos, S. Suresh Determination of elastoplastic properties by instrumented sharp indentation. Scr. Mater. 40, 1191 (1999)

T.A. Venkatesh, Van K.J. Vliet, A.E. Giannakopoulos, S. Suresh Determination of elasto-plastic properties by instrumented sharp indentation: Guidelines for property extraction. Scr. Mater. 42, 833 (2000)

J.L. Bucaille, S. Stauss, E. Felder, J. Michler Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 51, 1663 (2003)

K.D. Bouzakis, N. Michailidis Coating elastic-plastic properties determined by means of nanoindentations and FEM-supported evaluation algorithms. Thin Solid Films 469–470, 227 (2004)

Y.T. Cheng, C.M. Cheng Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 73, 614 (1998)

Y.T. Cheng, C.M. Cheng What is indentation hardness? Surf. Coat. Technol. 133–134, 417 (2000)

J. Malzbendera, de G. With Indentation load–displacement curve, plastic deformation, and energy. J. Mater. Res. 17, 502 (2002)

K.W. McElhaney, J.J. Vlassak, W.D. Nix Determination of indenter tip geometry and indentation contact area for depth-sensing indentation experiments. J. Mater. Res. 13, 1300 (1998)

J. Mencik, M.V. Swain Error associated with depth sensing micro-indentation. J. Mater. Res. 10, 1491 (1995)

J. Alcala, A.C. Barone, M. Anglada The influence of plastic hardening on surface deformation modes around Vickers and spherical indents. Acta Mater. 48, 3451 (2000)

Y. Choi, H.S. Lee, D. Kwon Analysis of sharp-tip-indentation load-depth curve for contact area determination taking into account pile-up and sink-in effects. J. Mater. Res. 19, 3307 (2004)

Y.H. Lee, J.H. Hahn, S.H. Nahm, J.I. Jang, D. Kwon Investigations on indentation size effects using a pile-up corrected hardness. J. Phys. D: Appl. Phys. 41, 074027 (2008)

ISO/FDIS 14577-1 Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters; Part 1, Test Method (International Organization for Standardization, Geneva, Switzerland 2002)

ASTM E8-04 Standard Test Methods for Tension Testing of Metallic Materials (ASTM International, W, Conshohocken, PA 2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, SK., Kim, JY., Chan, PP. et al. Conventional Vickers and true instrumented indentation hardness determined by instrumented indentation tests. Journal of Materials Research 25, 337–343 (2010). https://doi.org/10.1557/JMR.2010.0045

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2010.0045