Abstract

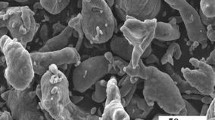

To impart machinability to hard and brittle AlN ceramics without losing their high thermal conductivity, a homogeneous dispersion of fine BN particles in an AlN matrix was investigated. A homogeneous dispersion of BN particles was obtained by pressureless sintering of turbostatic BN-coated AlN nanocomposite powder (AlN–BN nanocomposite powder), which was prepared by reducing and heating AlN particles containing a mixture of boric acid, urea, and carbon. Though AlN is slightly oxidized by boric acid during the reduction, the addition of carbon reduced the oxygen content of the AlN–BN composite powder by carbothermal reduction of the oxidized AlN particles. As a result, the thermal conductivity of the sintered material increased with decreasing oxygen content of the nanocomposite powder. AlN–BN nanocomposites containing more than 20 vol% BN showed high strength, machinability, and relatively high thermal conductivity in comparison with the conventional microcomposites.

Similar content being viewed by others

References

M.P. Borom, G.A. Slack, J.W. Szymaszek: Thermal conductivity of commercial alumium nitride. Am. Ceram. Soc. Bull. 51, 852 1972

G-F. Xu, T. Olorunyolemi, O.C. Wilson, I.K. Lloyd, Y. Carmel: Microwave sintering of high-density, high thermal conductivity AlN. J. Mater. Res. 17, 2837 2002

G-F. Xu, Y. Carmel, T. Olorunyolemi, I.K. Lloyd, O.C. Wilson Jr.: Microwave sintering and properties of AlN/TiB2 composites. J. Mater. Soc. 18, 66 1989

J. Tatami, K. Komeya, T. Meguro, S. Iwasawa, M. Komatsu: Fracture behavior of high thermal conductive aluminum nitride. Ceram. Eng. Sci. Proc. 20, 411 1999

N. Kuramoto, H. Taniguchi, I. Aso: Development of translucent aluminum nitride ceramics. Am. Ceram. Soc. Bull. 68, 883 1989

R.R. Lee: Development of high thermal conductivity aluminum nitride ceramic. J. Am. Ceram. Soc. 74, 2242 1991

K. Watari, H. Hwang, M. Toriyama, S. Kanzaki: Low-temperature sintering and high thermal conductivity of YLiO2-doped AlN ceramics. J. Am. Ceram. Soc. 79, 1979 1996

T. Jackson, A. Virkar, K. More, R. Dinwiddie: High-thermal-conductivity aluminum nitride ceramics: The effect of thermodynamic, kinetic, and microstructual factors. J. Am. Ceram. Soc. 80, 1421 1997

X. Luo, J. Li, B. Zhang, W. Li, H. Zhuang: High thermal conductivity aluminum nitride substrates prepared by aqueous tape casting. J. Am. Ceram. Soc. 89, 836 2006

A.W. Weimer, G.A. Cochran, G.A. Eisman, J.P. Henley, B.D. Hook, L.K. Mills, T.A. Guiton, A.K. Knudsen, N.R. Nicholas, J.E. Volmering, W.G. Moore: Rapid process for manufacturing aluminum nitride powder. J. Am. Ceram. Soc. 77, 3 1994

T. Yamakawa, J. Tatami, K. Komeya, T. Meguro: Synthesis of AlN powder from Al(OH)3 by reduction–nitridation in a mixture of NH3–C3H8 gas. J. Eur. Ceram. Soc. 26, 2413 2006

Z.A. Munir, W-S. Cho, M-W. Cho, J-H. Lee: Effects of h-BN additive on the microstructure and mechanical properties of AlN-based machinable ceramics. Mater. Sci. Eng., A 418, 61 2006

H-Y. Jin, W. Wang, J-Q. Gao, G-J. Qiao, Z-H. Jin: Fabrication and properties of machinable AlN-BN ceramic nanocomposites. Key Eng. Mater. 317-318, 637 2006

T. Kusunose, T. Sekino, B-S. Kim, Y-H. Choa, T. Nomoto, Y. Yamamoto, K. Niihara: Properties of hot-pressed AlN/BN nanocomposites. Mater. Sci. Forum 439, 131 2003

A. Lipp, K.A. Schwetz, K. Hunold: Hexagonal boron nitride: Fabrication, properties and applications. J. Eur. Ceram. Soc. 5, 3 1989

V. Brozek, M. Hubacek: A contribution to the crystallochemistry of boron nitride. J. Solid State Chem. 100, 120 1992

G-J. Zhang, J-F. Yang, M. Ando, T. Ohji: Nonoxide-boron nitride composites: In situ synthesis, microstructure and properties. J. Eur. Ceram. Soc. 22, 2551 2002

G-J. Zhang, J-F. Yang, M. Ando, T. Ohji, S. Kanzaki: Reactive synthesis of alumina-boron nitride composites. Acta Mater. 52, 1823 2004

D. Goeuriot-Launay, G. Brayet, F. Thevenot: Boron nitride effect on the thermal shock resistance of an alumina-based ceramic composite. J. Mater. Sci. Lett. 5, 940 1986

T. Kusunose, T. Sekino, Y-H. Choa, K. Niihara: Fabrication and microstructure of silicon nitride/boron nitride nanocomposites. J. Am. Ceram. Soc. 85, 2678 2002

K. Niihara: New design concept of structural ceramics-ceramic nanocomposites. J. Ceram. Soc. Jpn. 99, 974 1991

J. Zhao, L.C. Stearns, M.P. Harmer, H.M. Chan, G.A. Miller, R.E. Cook: Mechanical behavior of alumina-silicon carbide “nanocomposites.” J. Am. Ceram. Soc. 76, 503 1993

T. Sekino, T. Nakajima, S. Ueda, K. Niihara: Reduction and sintering of a nickel-dispersed-alumina composite and its properties. J. Am. Ceram. Soc. 80, 1139 1997

S-T. Oh, T. Sekino, K. Niihara: Fabrication and mechanical properties of 5 vol% copper dispersed alumina nanocomposite. J. Eur. Ceram. Soc. 18, 31 1998

T. Ohji, Y-K. Jeong, Y-H. Choa, K. Niihara: Strengthening and toughening mechanisms of ceramic nanocomposites. J. Am. Ceram. Soc. 81, 1453 1998

T. Kusunose: Fabrication of boron nitride dispersed nanocomposites by chemical processing and their mechanical properties. J. Ceram. Soc. Jpn. 114, 167 2006

W-S. Cho, Z-H. Piao, K-J. Lee, Y-C. Yoo, J-H. Lee, M-W. Cho, Y-C. Hong, K. Park, W-S. Hwang: Microstructure and mechanical properties of AlN-hBN based machinable ceramics prepared by pressureless sintering. J. Eur. Ceram. Soc. 27, 1425 2007

G.A. Slack, R.A. Tanzilli, R.O. Pohl, J.W. Vandersande: The intrinsic thermal conductivity of AlN. J. Phys. Chem. Solids 48, 641 1987

G.A. Slack: Nonmetallic crystals with high thermal conductivity. J. Phys. Chem. Solids 34, 321 1973

Acknowledgments

The authors would like to thank Mr. Takanori Tanaka (Materials Analysis Center, ISIR, Osaka University) for help with XRD measurements. This work was supported by Industrial Technology Research Grant Program from New Energy and Industrial Technology Development Organization (NEDO) and by Research Grant 2007 from The Die and Mold Technology Promotion Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kusunose, T., Sekino, T., Ando, Y. et al. Fabrication of machinable AlN–BN composites with high thermal conductivity by pressureless sintering turbostatic BN-coated AlN nanocomposite powders. Journal of Materials Research 23, 236–244 (2008). https://doi.org/10.1557/JMR.2008.0022

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0022