Abstract

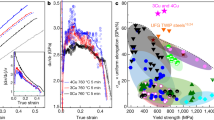

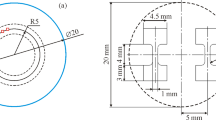

Bulk samples of an ultrafine-grained tungsten–tantalum composite alloy have been synthesized by consolidating mechanically milled composite powders. The grain growth during densification is limited due to the submicron-scale layering of the individual metals in the composite particles and the relatively low sintering temperature (1300 °C). The ultrafine microstructure of the high-density (∼99% theoretical density) samples leads to a high yield stress of ∼3 GPa under quasi-static uniaxial compression. A tendency for Ta-rich solid-solution formation during densification was observed, and the high-temperature phase equilibria in the composite powders were examined further using high-energy x-ray diffraction at temperatures up to 1300 °C.

Similar content being viewed by others

References

M.A. Meyers, A. Mishra D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427 2006

C.J. Youngdahl, P.G. Sanders, J.A. Eastman J.R. Weertman: Compressive yield strengths of nanocrystalline Cu and Pd. Scripta Mater. 37, 809 1997

J.E. Carsley, A. Fisher, W.W. Milligan E.C. Aifantis: Mechanical behavior of a bulk nanostructured iron alloy. Metall. Mater. Trans. A 29, 2261 1998

D. Jia, K.T. Ramesh E. Ma: Effects of nanocrystalline and ultrafine grain sizes on constitutive behavior and shear bands in iron. Acta Mater. 51, 3495 2003

Q. Wei, T. Jiao, S.N. Mathaudhu, E. Ma, K.T. Hartwig K.T. Ramesh: Microstructure and mechanical properties of tantalum after equal channel angular extrusion (ECAE). Mater. Sci. Eng., A 358, 266 2003

C.Z. Duan, M.J. Wang, J.Z. Pang G.H. Li: A calculation model of shear strain and strain rate within shear band in a serrated chip formed during high-speed machining. J. Mater. Proc. Technol. 178, 274 2006

N. He, T.C. Lee, W.S. Lau S.K. Chan: Assessment of deformation of a shear localized chip in high speed machining. J. Mater. Proc. Technol. 129, 101 2002

B.K. Kad, J-M. Gebert, M.T. Perez-Prado, M.E. Kassner M.A. Meyers: Ultrafine-grain-sized zirconium by dynamic deformation. Acta Mater. 54, 4111 2006

G.J. Fan, G.Y. Wang, H. Choo, P.K. Liaw, Y.S. Park, B.Q. Han E.J. Lavernia: Deformation behavior of an ultrafine-grained Al-Mg alloy at different strain rates. Scripta Mater. 52, 929 2005

R. Valiev: Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 3, 511 2004

C.C. Koch: Synthesis of nanostructured materials by mechanical milling: Problems and opportunities. Nanostruct. Mater. 9, 13 1997

L. Margulies, M.J. Kramer, R.W. McCallum, S. Kycia, D.R. Haeffner, J.C. Lang A.I. Goldman: New high temperature furnace for structure refinement by powder diffraction in controlled atmospheres using synchrotron radiation. Rev. Sci. Instrum. 70, 3554 1999

J. Wittenauer T.G. Nieh: Fine-grained W–Cu–Co alloys in Tungsten and Tungsten Alloys Recent Advances edited by A. Crowson and E.S. Chen TMS Warrendale, PA 1991

H.J. Ryu, S.H. Hong W.H. Baek: Microstructure and mechanical properties of mechanically alloyed and solid-state sintered tungsten heavy alloys. Mater. Sci. Eng., A 291, 91 2000

M.H. Lee D.J. Sordelet: Shear localization of nanoscale W in metallic glass composites. J. Mater. Res. 21, 492 2006

R.M. German E. Olevsky: Strength predictions for bulk structures fabricated from nanoscale tungsten powders. Int. J. Refract. Met. Hard Mater. 23, 77 2005

R.M. German E. Olevsky: Mapping the compaction and sintering response of tungsten-based materials into the nanoscale size range. Int. J. Refract. Met. Hard Mater. 23, 294 2005

Q. Xu, R.W. Hayes E.J. Lavernia: Creep properties of ball-milled and HIPed pure tantalum. Scripta Mater. 45, 447 2001

A.D. Romig M.J. Cieslak: Interdiffusion in the Ta–W system. J. Appl. Phys. 58, 3425 1985

K. Vieregge D. Gupta: Diffusion processes in tungsten metal alloys, thin films and foils in Tungsten and Tungsten Alloys Recent Advances edited by A. Crowson and E.S. Chen TMS Warrendale, PA 1991

B.E. Warren: X-ray Diffraction Dover Publications, Inc New York 1990

B.D. Cullity Elements of X-ray Diffraction, 2nd ed. Addison-Wesley Publishing Company, Inc. Reading, PA 1978

Th.H. de Keijser, J.I. Langford, E.J. Mittemeijer A.B.P. Vogels: Use of the Voigt function in a single-line method for the analysis of x-ray-diffraction line broadening. J. Appl. Crystallogr. 15, 308 1982

H.P. Klug L.E. Alexander: X-ray Diffraction Procedures John Wiley & Sons New York 1974

Q. Wei, T. Jiao, K.T. Ramesh, E. Ma, L.J. Kecskes, L. Magness, R. Dowding, V.U. Kazykhanov R.Z. Valiev: Mechanical behavior and dynamic failure of high-strength ultrafine grained tungsten under uniaxial compression. Acta Mater. 54, 77 2006

U.K. Vashi, R.W. Armstrong G.E. Zima: Hardness and grain size of consolidated fine tunsten powder. Metall. Trans. 1, 1769 1970

Q. Wei, H.T. Zhang, B.E. Schuster, K.T. Ramesh, R.Z. Valiev, L.J. Kecskes, R.J. Dowding, L. Magness K. Cho: Microstructure and mechanical properties of super-strong nanocrystalline tungsten processed by high-pressure torsion. Acta Mater. 54, 4079 2006

K.T. Hartwig, S.N. Mathaudhu, H.J. Maier I. Karaman: Ultrafine grained materials II in Ultrafine Grained Materials II edited by Y.T. Zhu, T.G. Langdon, R.S. Mishra, S.L. Semiatin, M.J. Saran, and T.C. Lowe TMS Warrendale, PA 2002

Q. Wei, K.T. Ramesh, E. Ma, L.J. Kesckes, R.J. Dowding, V.U. Kazykhanov R.Z. Valiev: Plastic flow localization in bulk-tungsten with ultrafine microstructure. App. Phys. Lett. 86, 101907 2005

Y. Bai B. Dodd: Adiabatic Shear Localization Pergamon Press New York 1992

A.M. Lennon K.T. Ramesh: The thermoviscoplastic response of polycrystalline tungsten in compression. Mater. Sci. Eng., A 276, 9 2000

Q. Wei, T. Jiao, K.T. Ramesh E. Ma: Nano-structured vanadium: processing and mechanical properties under quasi-static and dynamic compression. Scripta Mater. 50, 359 2004

Acknowledgments

The authors would like to thank Prof. A. Bastrows for assistance with the mechanical testing and Mr. H. Salisbury for assistance with sample preparation. The authors are grateful to Dr. M.H. Lee and Prof. Q. Wei for their useful comments and suggestions. The work at the Ames Laboratory was supported by the United States Department of Energy, Office of Basic Energy Sciences, and by Iowa State University under Contract No. DE-AC02-07CH11358. The high-energy x-ray work at the MUCAT sector of the Advanced Photon Source was supported by the United States Department of Energy, Office of Science, Basic Energy Sciences under Contract No. W-31-109-Eng-38.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ott, R., Yang, X., Guyer, D. et al. Synthesis of high-strength W–Ta ultrafine-grain composites. Journal of Materials Research 23, 133–139 (2008). https://doi.org/10.1557/JMR.2008.0007

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0007