Abstract

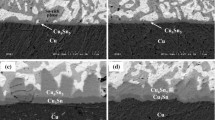

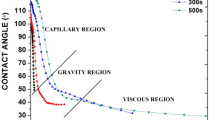

Sn–3.5Ag solder bumps were formed on electroless Ni/immersion Au (Ni/Au) and organic solderability preservative (OSP) surface-finished bond pads, respectively. The shear strength of the solder bumps was measured as a function of reflow steps. Fracture surfaces and interfacial microstructures were investigated by scanning electron microscope. The shear strength of Ni/Au samples increased up to the seventh reflow step and subsequently decreased after the tenth reflow step. Spalling of Ni3Sn4 intermetallic compounds (IMCs) and the P-rich Ni layer strengthened and weakened the bond, respectively. For OSP samples, although Cu6Sn5 IMCs grew as the reflow step was repeated, no remarkable change in shear strength was observed. Interfacial fractures of OSP samples occurred at the interface between Cu6Sn5 IMC and Cu3Sn IMC. Fracture surfaces of OSP samples showed concave pits that consisted of a Cu3Sn bottom and an Sn wall. The pits were formed by separation of Cu6Sn5 IMC from Cu3Sn IMC and the molten Sn channel between the Cu6Sn5 IMC grains.

Similar content being viewed by others

References

S.K. Kang, D.Y. Shih, K. Fogel, P. Lauro, M.J. Yim, G.G. Advocate Jr. M. Griffin, C. Goldsmith, D.W. Henderson, T.A. Gosselin, D.E. King, J.J. Konrad, A. Sarkhel and K.J. Puttlitz: Interfacial reaction studies on lead (Pb)-free solder alloys. IEEE Trans-EPM 25, 155 (2002).

S.K. Kang, W.K. Choi, M.J. Yim and D.Y. Shih: Studies of the mechanical and electrical properties of lead-free solder joints. J. Electron. Mater. 31, 1292 (2002).

Y.C. Sohn, J. Yu, S.K. Kang, D.Y. Shih and T.Y. Lee: Spalling of intermetallic compounds during the reaction between lead-free solders and electroless Ni-P metallization. J. Mater. Res. 19, 2428 (2004).

M.N. Islam, Y.C. Chan, A. Sharif and M.O. Alam: Comparative study of the dissolution kinetics of electrolytic Ni and electroless Ni-P by the molten Sn3.5Ag0.5Cu solder alloy. Microelectron. Reliab. 43, 2031 (2003).

M. He, W.H. Lau, G. Qi and Z. Chen: Intermetallic compound formation between Sn–3.5Ag solder and Ni-based metallization during liquid state reaction. Thin Solid Films 462–463, 376 (2004).

M. He, Z. Chen and G. Qi: Solid state interfacial reaction of Sn–37Pb and Sn–3.5Ag solders with Ni–P under bump metallization. Acta Mater. 52, 2047 (2004).

Y. Li: An experimental study on organic solderability preservative. In Proceedings of the IEEE/CPMT International Electronics Manufacturing Technology Symposium, New York, NY, 1997; p. 56.

C.Y. Liu, C. Chen, A.K. Mal and K.N. Tu: Direct correlation between mechanical failure and metallurgical reaction in flip chip solder joints. J. Appl. Phys. 85, 3882 (1999).

Y.H. Liu, C.M. Chuang and K.L. Lin: Failure behavior upon shear test of 5Sn–95Pb solder bump after high temperature reliability test. J. Mater. Res. 19, 2471 (2004).

S.T. Nurmi, J.J. Sundelin, E.O. Ristolainen and T. Lepistö: The influence of multiple reflow cycles on solder joint voids for lead-free PBGAs. Solder. Surf. Mater. Technol. 15, 31 (2003).

D.R. Frear, S.N. Burchett, H.S. Morgan and J.H. Lau: The Mechanics of Solder Alloy Interconnects (Van Nostrand Reinhold, New York, 1994).

J.H. Westbrook and R.L. Fleischer Historical sketch, in Intermetallic Compounds (John Wiley & Sons Ltd., New York, 1967).

M.O. Alam, Y.C. Chan and K.N. Tu: Effect of reaction time and P content on mechanical strength of the interface formed between eutectic Sn-Ag solder and Au/electroless Ni(P)/Cu bond pad. J. Appl. Phys. 94, 4108 (2003).

P.G. Harris and K.S. Chaggar: The role of intermetallic compounds in lead-free soldering. Solder. Surf. Mt. Tech. 10, 38 (1998).

J.L. Marshall, J. Calderon, J. Sees, G. Lucey and J.S. Hwang: Composite solders. IEEE Trans-CHMT. 14, 698 (1991).

K. Mohankumar, A.A.O. Tay and V. Kripesh Nano-particle reinforced solders for fine pitch applications. Proceedings of the Electronics Packaging Technology Conference, New York, NY, 2004; p. 455.

M.O. Alam, Y.C. Chan and K.C. Hung: Reliability study of the electroless Ni-P layer against solder alloy. Microelectron. Reliab. 42, 1065 (2002).

A.A. Liu, H.K. Kim, K.N. Tu and P.A. Totta: Spalling of Cu6Sn5 spheroids in the soldering reaction of eutectic SnPb on Cr/Cu/Au thin films. J. Appl. Phys. 80, 2774 (1996).

H.K. Kim, H.K. Liou and K.N. Tu: Three-dimensional morphology of a very rough interface formed in the soldering reaction between eutectic SnPb and Cu. Appl. Phys. Lett. 66, 2337 (1995).

H.K. Kim and K.N. Tu: Kinetic analysis of the soldering reaction between eutectic SnPb alloy and Cu accompanied by ripening. Phys. Rev. B 53, 16027 (1996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, JS., Chu, KM. & Jeon, D.Y. Shear strength of Sn–3.5Ag solder bumps formed on Ni/Au and organic solderability preservative surface-finished bond pads after multiple reflow steps. Journal of Materials Research 20, 3088–3093 (2005). https://doi.org/10.1557/JMR.2005.0380

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0380