Abstract

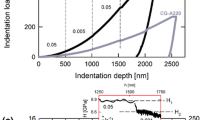

Using depth-sensing indentation with sub-nanometer displacement resolution, the plastic deformation of a range of materials, including a metallic glass, amorphous selenium, Ni3Al, pure Nb, Al, Cu, and Zn metals, and an Al-Mg alloy, has been investigated at room temperature. In amorphous selenium, even the sub-nanometer displacement resolution of the nanoindentation technique cannot reveal any strain burst during deformation at room temperature. In all other metals studied, what may appear to be smooth load-displacement curves at macroscopic scale during indentation deformation in fact turn out to consist of a continuous series of random bursts of the nanometer scale. The occurrence probability of the bursts is found to decrease at increasing burst size. In all of the crystalline metals and alloys studied, the size distribution of the strain bursts seems to follow an exponential law with a characteristic length scale. The absence of the self-organized critical behavior is likely a result of the small size of the strained volume in the nanoindentation situation, which gives rise to a constraint of a characteristic strain. In the metallic glass sample, due to the limited range of the burst sizes encountered, whether the deformation bursts follow an exponential or a power-law behavior corresponding to self-organized criticality is inconclusive. From a theoretical viewpoint based on the Shannon entropy, the exponential distribution is the most likely distribution at a given mean burst size, and this is thought to be the reason for its occurrence in different materials.

Similar content being viewed by others

References

P. Bak, C. Tang and K. Wiesenfeld: Self-organized criticality: An explanation of 1/f noise. Phys. Rev. Lett. 59, 381 (1987).

P. Bak: How Nature Works (Springer-Verlag, Berlin, Germany, 1996).

De J.T. Hosson.M., G. Boom, U. Schlagowski and O. Kanert: Solution hardening in Al-Zn alloys. Acta Metall. 34, 1571 (1986).

M.-C. Miguel, A. Vespingnani, S. Zapperi, J. Weiss and J.-R. Grasso: Intermittent dislocation flow in viscoplastic deformation. Nature 410, 667 (2001).

P. Häfner, K. Bay and M. Zaiser: Fractal dislocation patterning during plastic deformation. Phys. Rev. Lett. 81, 2470 (1998).

M. Zaiser, K. Bay and P. Häfner: Fractal analysis of deformation-induced dislocation patterns. Acta Mater. 47, 2463 (1999).

A.H.W. Ngan: Dislocation patterning—A statistical mechanics perspective. Scripta Mate. 52, 1005 (2005).

Y. Golovin.I., V.I. Ivolgin, V.A. Khonik, K. Kitagawa and A.I. Tyurin: Serrated plastic flow during nanoindentation of a bulk metallic glass. Scripta Mater. 45, 947 (2001).

T.G. Nieh, C. Schuh, J. Wadsworth and Y. Li: Strain rate-dependent deformation in bulk metallic glasses. Intermetallics 10, 1177 (2002).

C.A. Schuh, T.G. Nieh and Y. Kawamura: Rate dependence of serrated flow during nanoindentation of a bulk metallic glass. J. Mater. Res. 17, 1651 (2002).

C.A. Schuh, A.S. Argon, T.G. Nieh and J. Wadsworth: The transition from localized to homogeneous plasticity during nanoindentation of an amorphous metal. Philos. Mag. 83, 2585 (2003).

C.A. Schuh and T.G. Nieh: A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 51, 87 (2003).

A. Savitzky and M.J.E. Golay: Smoothing and differentiation of data by simplified least squares procedures. Anal. Chem. 36, 1627 (1964).

A.F. Bower, N.A. Fleck, A. Needleman and N. Ogbonna: Indentation of a power law creeping solid. Proc. R. Soc. London, Ser. A 441, 97 (1993).

B. Tang and A.H.W. Ngan Measurement of viscoelastic properties of amorphous selenium using depth-sensing indentation. To appear in Soft Mater. 2, 125 (2005).

Y.I. Golovin, V.I. Ivolgin and M.A. Lebedkin: Unstable plastic flow in the Al-3%Mg alloy in the process of continuous nanoindentation. Phys. Solid State 44, 1310 (2002).

G. Bérces, J. Lendvai, A. Juhász and N.Q. Chinh: Dynamic characterization of Portevin-Le Châtelier instabilities occurring in depth-sensing microhardness tests. J. Mater. Res. 18, 2874 (2003).

W.A. Soer, De J.T. Hosson.M., A.M. Minor, J.W. Morris Jr. and E.A. Stach: Effects of solute Mg on grain boundary and dislocation dynamics during nanoindentation of Al-Mg thin films. Acta Mater. 52, 5783 (2004).

N.Q. Chinh, J. Gubicza, Z. Kovács. and J. Lendvai: Depth-sensing indentation tests in studying plastic instabilities. J. Mater. Res. 19, 31 (2004).

Z. Kovács., N.Q. Chinh, J. Lendvai and G. Vörös: Portevin–Le Châtelier type plastic instabilities in depth sensing macro-indentation. Mater. Sci. Eng. A325, 255 (2002).

P.B. Hirsch: A model of the anomalous yield stress for (111) slip in L12 alloys. Prog. Mater. Sci. 36, 63 (1992).

A.H.W. Ngan, M. Wen and C.H. Woo: Atomistic simulations of Paidar–Pope–Vitek lock formation in Ni3Al. Comput. Mater. Sci. 29, 259 (2004).

A.H.W. Ngan and M. Wen: Dislocation kink-pair energetics and pencil glide in body-centered-cubic crystals. Phys. Rev. Lett. 87, 075505 (2001).

D. Caillard and A. Couret: Dislocation movements controlled by friction forces and local pinning in metals and alloys. Mater. Sci. Eng. A322, 108 (2002).

G. Molenat and D. Caillard: Dislocation mechanisms in Ni3Al at room-temperature—In situ straining experiments in TEM. Philos. Mag. A 64, 1291 (1991).

C.E. Shannon: A mathematical theory of communication. Bell Syst. Tech. J. 27, 379 623–656(1948).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Ngan, A.H.W. & Wang, M.G. Continuous strain bursts in crystalline and amorphous metals during plastic deformation by nanoindentation. Journal of Materials Research 20, 3072–3081 (2005). https://doi.org/10.1557/JMR.2005.0379

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0379