Abstract

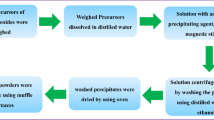

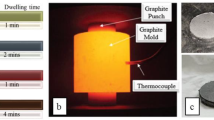

Ultra-refractory ceramic composites of composition ZrB2 + (5 to 20) vol% MoSi2 were produced by pressureless sintering at 1830 °C under argon atmosphere. Sintering cycles and microstructural analysis point out that at least 20 vol% molybdenum disilicide is necessary for obtaining a dense material. Thereafter, the composite 80 vol% ZrB2 + 20 vol% MoSi2 was used to test the thermal stability under oxidizing environment. Oxidation tests were carried out in flowing synthetic air in a thermogravimetric analyzer from 700 to 1400 °C with exposure time of 30 h. In the low-temperature range (700–1000 °C), the oxidation of the composite resembles that of monolithic ZrB2 ceramics, for temperatures >1200 °C the silica resulting from oxidation of molybdenum disilicide seals the sample surface, preventing zirconium diboride from fast degradation.

Similar content being viewed by others

References

F. Monteverde, A. Bellosi, and S. Guicciardi: Processing and properties of zirconium diboride-based composites. J. Eur. Ceram. Soc. 22, 279 (2002).

F. Monteverde, S. Guicciardi, and A. Bellosi: Advances in microstructure and mechanical properties of zirconium diboride based ceramics. Mater. Sci. Eng. A346, 310 (2003).

F. Monteverde and A. Bellosi: Beneficial effects of AlN as sintering aid on microstructure and mechanical properties of hotpressed ZrB2. Adv. Eng. Mater. 7, 508 (2003).

G-J. Zhang, Z-Y. Deng, N. Kondo, J-F. Yang, and T. Ohji: Reactive hot pressing of ZrB2-SiC composites. J. Am. Ceram. Soc. 83, 2330 (2000).

W.C. Tripp and H.C. Graham: Thermogravimetric study of the oxidation of ZrB2 in the temperature range of 800 to 1500 °C. J. Electrochem. Soc. 118, 1195 (1971).

J.B. Berkowitz-Mattuck: High-temperature oxidation, III-Zirconium and hafnium diborides. J. Electrochem. Soc. 113, 908 (1966).

W.C. Tripp, H.H. Davis, and H.C. Graham: Effect of an SiC addition on the oxidation of ZrB2. Ceram. Bull. 52, 612 (1973).

T. Mizutani and A. Tsuge: Effects of metallic boride dispersion on fracture toughness and oxidation resistance in SiC ceramics. J. Ceram. Soc. Japan. Int. Ed. 100, 991 (1992).

F. Monteverde and A. Bellosi: Oxidation of ZrB2-based ceramics in dry air. J. Electrochem. Soc. 150, B552 (2003).

E.J. Opila and M.C. Halbig: Oxidation of ZrB2-SiC, in Ceramic Engineering and Science Proceedings, edited by M. Singh and T. Jessen (ACERS, 22, Westerville, OH, 2001), p. 221–228.

M.M. Opeka, I.G. Talmy, E.J. Wuchina, J.A. Zaykosky, and S.J. Causey: Mechanical thermal and oxidation properties of refractory hafnium and zirconium compounds. J. Eur. Ceram. Soc. 19, 2405 (1999).

C.R. Wang, J.M. Yang, and W. Hoffman: Thermal stability of refractory carbide/boride composites. Mater. Chem. Phys. 74, 272 (2002).

Y-L. Jang and E.J. Lavernia: Review: Processing of molybdenum disilicide. J. Mater. Sci. 29, 2557 (1994).

C.G. McKamey, P.F. Tortorelli, J.H. Devan, and C.A. Carmichael: A study of pest oxidation in polycrystalline Mo Si2. J. Mater. Res. 7, 2747 (1992).

P.J. Meschter: Low-temperature oxidation of molybdenum disilicide. Metall. Trans. 23, 1763 (1992).

T.C. Chou and T.G. Nieh: Mechanism of MoSi2 pest during low temperature oxidation. J. Mater. Res. 8, 214 (1993).

K. Natesan and S.C. Deevi: Oxidation behaviour of molybdenum silicides and their composites. Intermetallics 8, 1147 (2000).

Y.T. Zhu, L. Shu, and D.P. Butt: Kinetics and products of molybdenum disilicide powder oxidation. J. Am. Ceram. Soc. 85, 507 (2002).

K. Kurokawa, H. Houzumi, I. Saeki, and H. Takahashi: Low temperature oxidation of fully dense and porous MoSi2. Mater. Sci. Eng. A261, 292 (1999).

K. Yanagihara, T. Maruyama, and N. Kazuhiro: Effect of third elements on the pesting suppression of Mo–Si–X intermetallics (X β Al, Ta, Ti, Zr and Y). Intermetallics 4, S133 (1996).

H.M. Yokota, T. Kudoh, and T. Suzuki: Oxidation resistance of boronized MoSi2. Surf. Coat. Technol. 169–170, 171 (2003).

A.L. Chamberlain, W.G. Fahrenholtz, and G.H. Hilmas: Characterization of zirconium diboride-molybdenum disilicide ceramics, in Advances in Ceramic Matrix Composites, Ceramic Transactions, edited by N.P. Bansal, J.P. Singh, W.M. Kriven, and H. Schneider (Am. Ceram. Soc., 153, Westerville, OH, 2003), p.299.

P.T.B. Shaffer: An oxidation resistant boride composition. Ceram. Bull. 41, 96 (1962).

M.M. Opeka, I.G. Talmy, and J.A. Zaykoski: Oxidation-based materials selection for 2000°C + hypersonic aerosurfaces: theoretical considerations and historical experience. J. Mater. Sci. 39, 5887 (2004).

D. Sciti, S. Guicciardi, C. Melandri, and A. Bellosi: Hightemperature resistant in the AlN–SiC–MoSi2 system. J. Am. Ceram. Soc. 86, 1720 (2003).

J.I. Lee, N.L. Hecht, and T-I. Mah: In-situ processing and properties of SiC/MoSi2 nanocomposites. J. Am. Ceram. Soc. 81, 421 (1998).

A.E. McHale: Phase Diagram for Ceramists (Am. Ceram. Soc., 10, Westerville, OH, 1994), p. 144.

A.E. McHale: Phase Diagram for Ceramists (Am. Ceram. Soc., 10, Westerville, OH, 1994), p. 136.

A.E. McHale: Phase Diagram for Ceramists (Am. Ceram. Soc., 10, Westerville, OH, 1994), p. 174.

HSC Chemistry for Windows 5, Outokumpu Research Oy, Pori, Finland (2002).

C. Veytizou, J.F. Quinson, O. Valfort, and G. Thomas: Zircon formation from amorphous silica and tetragonal zirconia: Kinetic study and modelling. Solid State Ionics 139, 315 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sciti, D., Brach, M. & Bellosi, A. Oxidation behavior of a pressureless sintered ZrB2–MoSi2 ceramic composite. Journal of Materials Research 20, 922–930 (2005). https://doi.org/10.1557/JMR.2005.0111

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0111