Abstract

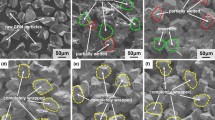

We investigated a new method of ceramic-to-metal joining, referred to as reactive air brazing, as a potential method of sealing ceramic components in high-temperature electrochemical devices. Sessile drop wetting experiments and joint strength testing were conducted using yttria stabilized zirconia (YSZ) substrates and CuO–Ag-based air brazes. Results from our studies indicate that the wettability of the braze improves substantially with increasing CuO content, over a compositional range of 1–8 mol% CuO, which is accompanied by an increase in the bend strength of the corresponding brazed YSZ joint. The addition of a small amount of TiO2 (0.5 mol%) to the CuO–Ag braze further improves wettability due to the formation of a titanium zirconate reaction product along the braze/substrate interface. However, with one notable exception, the bend strength of these ternary braze joints remained nearly identical to those measured in comparable binary braze joints. Scanning electron microscopy analysis conducted on the corresponding fracture surfaces indicated that in the binary braze joints, failure occurs primarily at the braze/YSZ interface. Similarly in the case of the ternary, TiO2-doped brazes joint failure occurs predominantly along the interface between the braze filler metal and the underlying titanium zirconate reaction layer.

Similar content being viewed by others

References

K. Eichler, G. Solow, P. Otschik, and W. Schaffrath: Degradation effects of sealing glasses for the SOFG, in Proceedings of the Fourth European Solid Oxide Fuel Cell Forum, edited by A.J. McEvoy (European Fuel Cell Forun, Oberrohrdorf, Switzerland, 2000), p. 899.

M. Singh, T. Shibayama, T. Hinoki, M. Ando, Y. Katoh, and A. Kohyama: Joining of silicon carbide composites for fusion energy applications. J. Nucl. Mater. 283–287B, 1258 (2000).

E. Pippel, J. Woltersdorf, P. Colombo, and A. Donato: Structure and composition of interlayers in joints between SiC bodies. J. Eur. Ceram, Soc. 17, 1259 (1997).

J-H. Kim and Y-C. Yoo: Bonding of alumina to metals with Ag-Cu-Zr brazing alloy. J. Mater. Sci. Lett. 16, 1212 (1997).

J.P. Rice, D.M. Paxton, and K.S. Weil: Oxidation behavior of a commercial gold-based braze alloy for cermic-to-metal joining, in Ceramic Engineering and Science Proceedings, edited by H-T. Lin, and M. Singh (Am. Ceram. Soc, Westerville, OH, 2002), p. 809.

K.S. Weil, J.S. Hardy, and J.Y. Kim: Use of a novel ceramic-metals braze for joining in high-temperature electrochemical devices, in The Joining of Advanced and Specialty Materials V, edited by J.E. Indacochea, J.N. DuPont, T.J. Lienert, W. Tillmann, N. Sobczak, W.F. Gale, and M. Singh (ASM International, Materials Park, OH, 2003), p. 47.

J.S. Hardy, J.Y. Kim, and K.S. Weil: Joining mixed conducting oxides using an air-fired electrically conductive braze. J. Electro-chem. Soc. 151, J43 (2004).

J.Y. Kim and K.S. Weil: Development of a copper oxide - silver braze for ceramic joining, in Advances in Joining of Ceramics, edited by Charles A. Lewinsohn, Mrityunjay Singh, and Ronald Loehman (Ceramic Transaction 138, American Ceramic Society, Westerville, OH, 2002), pp. 119–132.

J.Y. Kim, J.S. Hardy, and K.S. Weil: Effects of CuO content on wetting behavior and mechanical properties of CuO–Ag braze for ceramic joining. J. Am. Ceram. Soc. (in press).

A.M. Meier, P.R. Chidambaram, and G.R. Edwards: A comparison of the wettability of copper-copper oxide and silver-copper oxide on polycrystalline alumina. J. Mater. Sci. 30, 4781 (1995).

C.C. Shüler, A. Stuck, N. Beck, H. Keser, and U. Täck: Direct silver bonding—An alternative for substrates in power semiconductor packaging. J. Mater. Sci. Mater. Electron, 11, 389 (2000)

F-H. Lu, F-X. Fang, and Y-S. Chen: Eutectic reaction between copper oxide and titanium dioxide. J. Eur. Cer. Soc. 21, 1093 (2001).

D.A. Mortimer and M.G Nicholas: The wetting of carbon and carbides by copper alloys. J. Mater. Sci. 8, 640 (1973).

M.R. Locatelli, A.P. Tomsia, K. Nakashima, B.J. Dalgleish, and A.M. Glaeser: New strategies for joining ceramics for high-temperature applications. Key Eng. Mater. 111–112, 157 (1995).

J.W. Cahn: Critical point wetting. J. Chem. Phys. 66, 3667 (1977).

R.E. Reed-Hill: Physical Metallurgy Principle, 2nd ed. (D. Van Nostrand Company, New York, 1973), Chap. 10.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, J.Y., Hardy, J.S. & Weil, K.S. Silver-copper oxide based reactive air braze for joining yttria-stabilized zirconia. Journal of Materials Research 20, 636–643 (2005). https://doi.org/10.1557/JMR.2005.0088

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0088