Abstract

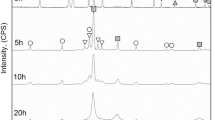

The solid-state reactions between Al and TiO2 that occur during heating an Al/TiO2 nanocomposite powder produced using high-energy mechanical milling have been studied using thermal analysis, x-ray diffractometry (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM) in combination with compositional microanalysis. It has been found that Al and TiO2 react in the temperature range from 650 to 800 °C, forming Al3Ti, but XRD analysis, SEM examination, and detailed TEM characterization of the powder particles heated to 800 °C show that the expected Al2O3 does not form. However, a–Al2O3 particles form during heating from 800 to 1000 °C. The possible reasons for the time gap between formation of Al3Ti and Al2O3 are discussed.

Similar content being viewed by others

References

P.C. Maity, P.N. Chakraborty and S.C. Panigrahi: Processing and properties of Al-Al2O3 (TiO2) in situ particle composite, J. Mater. Process. Technol. 53, 857 (1995).

C.F. Feng and L. Froyen: Formation of Al3Ti and Al2O3 from an Al-TiO2 system for preparing in-situ aluminium matrix composites, Composites Part A 31, 385 (2000).

I.C. Barlow, H. Jones and W.M. Rainforth: The effect of heat treatment at 500–655 °C on the microstructure and properties of mechanically alloyed Al-Ti-O based material, Mater. Sci. Eng. A 351, 344 (2003).

I.C. Barlow, H. Jones and W.M. Rainforth: Evolution of microstructure and hardening, and the role of Al3Ti coarsening, during extended thermal treatment in mechanically alloyed Al-Ti-O based materials, Acta Mater. 49, 1209 (2001).

H.X. Peng, D.Z. Wang, L. Geng, C.K. Yao, J. F and Mao: Evaluation of the microstructure of in-situ reaction processed Al3Ti-Al2O3-Al composite, Scripta Mater. 37, 199 (1997).

J. Pan, D.M. Yang, J.H. Li, X.G. Ning, H.Q. Ye, H. Fukunaga and Z.K. Yao: Microstructural study of the interface reaction between titania whiskers and aluminium, Compos. Sci. Technol. 57, 319 (1997).

I. Tsuchitori and H. Fukunaga: Effect of impurity elements on reaction of reinforcement with matrix in rutile type titanium oxide/aluminium composites, J. Jpn. Inst. Met. 59, 1306 (1995).

I. Tsuchitori, G. Sasaki and H. Fukunaga: Enhanced solid state reaction of TiO2/Al composites by doping, J. Jpn. Inst. Met. 61, 544 (1997).

N. Claussen, D.E. Garcia and R. Janssen: Reaction sintering of alumina-aluminide alloys (3A), J. Mater. Res. 11, 2884 (1996).

S. Schicker, D.E. Garcia, J. Bruhn, R. Janssen and N. Claussen: Reaction synthesized Al2O3-based intermetallic composites, Acta Mater. 46, 2485 (1998).

N.J. Welham: Mechanical activation of the solid-state reaction between Al and TiO2, Mater. Sci. Eng. A 255, 81 (1998).

D.L. Zhang and M. Newby: Titanium alloy based dispersion-strengthened composites, U.S. Patent No. US6 264 719 B1, 1999.

D.L. Zhang, D.Y. Ying and G. Adam: Reaction kinetics and microstructural evolution during heating high-energy ball milled Al-metal oxide composite powders, J. Metastable Nanocrystalline Mater. 13, 287 (2002).

D.L. Zhang, Z.H. Cai and M. Newby: Low cost Ti(Al,O)/Al2O3 and TixAly/Al2O3 composites, Mater. Tech. Adv. Performance Mater. 18, 94 (2003).

D.Y. Ying, D.L. Zhang and M. Newby: Solid state reactions during heating mechanically milled Al/TiO2 composite powders, Metall. Mater. Trans. A 35A, 2115 (2004).

W. Lefebvre, A. Loiseau, M. Thomas and A. Menand: Influence of oxygen on the α→γ massive transformation in a Ti-48at.%Al alloy, Philos. Mag. A 82, 2341 (2002).

G.J. Fan, M.X. Quan and Z.Q. Hu: Supersaturated Al(Ti) solid solutions with partial L12 ordering prepared by mechanical alloying, Scripta Metall. Mater. 33, 377 (1995).

M. Oehring, T. Klassen and R. Bormann: The formation of metastable Ti-Al solid solution by mechanical alloying and ball milling, J. Mater. Res. 8, 2819 (1993).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D.L., Ying, D.Y. & Munroe, P. Formation of Al2O3 during heating of an Al/TiO2 nanocomposite powder. Journal of Materials Research 20, 307–313 (2005). https://doi.org/10.1557/JMR.2005.0059

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0059