Abstract

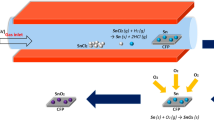

Silicon carbide (SiC) microtubes were synthesized and characterized via a vapor–solid (VS) reaction of carbon fiber (Csolid) and SiO(gas). The synthesis mechanisms were investigated. The precursor led complete conversion of [SiO(gas) + C(solid)] into [SiC(solid) + CO(gas)] through overall reaction under inert gas flow at and above 1350 °C. Carbon fibers with small surface area (0.7–2.0 m2 g-1) were gradually converted to SiC microtubes with large specific surface area (45–63 m2 g-1). Inner surface of SiC microtubes indicated a villus-like morphology, which consisted of submicron-sized SiC villi. The outer surface of the SiC microtubes was smooth. Inner surface morphology of SiC microtubes was dependent upon synthesizing temperature. Thickness of villus-like layer in SiC microtubes increased with increasing synthesizing temperature, showing 0.25 and 0.5 at 1350 and 1400 °C, respectively. Both VS and gas–liquid–solid (VLS) growth mechanisms were investigated in synthesis of SiC fiber as a reaction byproduct, and the reaction was governed by both growth mechanisms.

Similar content being viewed by others

References

R.S. Russel-Floyd, B. Harris, R.G. Cooke, J. Laurie, F.W. Hammett, R.W. Jones and T. Wang: Application of sol-gel processing techniques for the manufacture of fiber-reinforced ceramics, J. Am. Ceram. Soc. 76, 2635 (1993).

J.D. Mackenzie: Crystallization of gel-derived glasses, J. Non-Cryst. Solids 100, 162 (1988).

C. Vix-Guterl and P. Ehrburger: Effect of the properties of a carbon substrate on its reaction with silica for silicon carbide formation, Carbon 35, 1587 (1997).

C. Vix-Guterl, B. McEnaney and P. Ehrburger: SiC material produced by carbothermal reduction of a freeze gel silica-carbon artefact, J. Eur. Ceram. Soc. 19, 427 (1999).

P.W. Lednor: Synthesis, stability, and catalytic properties of high surface area silicon oxynitride and silicon carbide, Catal. Today 15, 243 (1992).

M.A. Vannice, Y.L. Chao and R.M. Friedman: The preparation and use of high surface area silicon carbide catalyst supports, Appl. Catal. 20, 91 (1986).

M. Kizling Boutonnet, P. Stenius, S. Andersson and A. Frestad: Characterization and catalytic activity of silicon carbide powder as catalyst support in exhaust catalysts, Appl Catal B: Environ. 1, 149 (1992).

R. Moene, H.T. Boon, J. Schooman, M. Makkee and J.A. Moulijn: Coating of activated carbon with silicon carbide by chemical vapour deposition, Carbon 34, 567 (1996).

M.J. Ledoux, J. Guille, S. Hantzer, and D. Dubots: Process for the production of silicon carbide with a large specific surface area and use for high-temperature catalytic reactions. U.S. Patent No. 4914070 (Pechiney Electrometallurgie, 1990).

M.J. Ledoux, S. Hantzer, C. Pham-Huu, J.L. Guille and M.P. Desaneaux: New synthesis and uses of high specific surface area SiC as a catalytic support that is chemically inert and has high thermal resistance, J. Catal. 114, 176 (1988).

N. Keller, C. Pham-Huu, S. Roy, M.J. Ledoux, Estournèc. S and J.L. Guille: Influence of the preparation conditions on the synthesis of high surface area SiC for use as a heterogeneous catalyst support, J. Mater. Sci. 34, 3189 (1999).

N. Keller, C. Pham-Huu, M.J. Ledoux, C. Estournes and G. Ehert: Preparation and characterization of SiC microtubes, Appl. Catal. A 187, 255 (1999).

J.W. Kim, S.S. Lee, D.H. Park, Y.G. Jung, J.H. Lee and C.Y. Jo: Effect of inert gas flow nature on the SiC microtube synthesis, Key Eng. Mater. (2004, in press).

C. Vix-Guterl, I. Alix, P. Gibot and P. Ehrburger: Formation of tubular silicon carbide from a carbon-silica material by using a reactive replica technique: Infra-red characterisation, Appl. Surf. Sci. 210, 329 (2003).

R. Moene, M. Makkee and J.A. Moulijin: High surface area silicon carbide as catalyst support characterization and stability, Appl. Catal. A 167, 321 (1998).

Y.H. Tang, Y.F. Zheng, C.S. Lee, N. Wang, S.T. Lee and T.K. Sham: Carbon monoxide-assisted growth of carbon nanotubes, Appl. Phys. Lett. 342, 259 (2001).

N.W. Hurst, S.J. Gentry, A. Jones and B.D. McNicol: Temperature programmed reduction, Catal. Rev. Sci. Eng. 24, 233 (1982).

J.L. Falconer and K.A. Schwartz: Temperature-programmed desorption and reaction: Applications to supported catalysts, Catal. Rev. Sci. Eng. 25, 141 (1983).

S.D. Robertson: Carbon formation from methane pyrolysis over some transition metal surfaces–I. Nature and properties of the carbons formed, Carbon 8, 365 (1970).

L. Wang, H. Wada and L.F. Allard: Synthesis and characterization of SiC whiskers, J. Mater. Res. 7, 148 (1992).

S.-W. Seo and K. Koumoto: Stacking faults in ß-SiC formed during carbothermal reduction of SiO2, J. Am. Ceram. Soc. 79, 1777 (1996).

J.V. Milevski, F.D. Gag, J.J. Petrovic and S.R. Skaggs: Growth of beta-silicon carbide whiskers by the VLS process, J. Mater. Sci. 20, 1160 (1985).

L. Geng and J. Zhang: A study of the crystal structure of a commercial ß–SiC whisker by high-resolution TEM, Mater. Cem. Phy. 84, 243 (2004).

L. Wang, H. Wada and L.F. Allard: Synthesis and characterization of SiC whiskers, J. Mater. Res. 7, 148 (1992).

J.V. Milevski, F.D. Gag, J.J. Petrovic and S.R. Skaggs: Growth of beta-silicon carbide whiskers by the VLS process, J. Mater. Sci. 20, 1160 (1985).

H. Wang, Y. Berta and G.S. Fischman: Microstructure of silicon carbide whiskers synthesized by carbothermal reduction of silicon nitride, J. Am. Ceram. Soc. 75, 1080 (1992).

R.D. Jong and R.A. McCauley: Growth of twinned ß-silicon carbide whiskers by the vapor-liquid-solid process, J. Am. Ceram. Soc. 70 C–338 (1987).

H.J. Choi and J.G. Lee: Continuous synthesis of silicon carbide whiskers, J. Mater. Sci. 30, 1982 (1995).

S.-W. Seo and K. Koumoto: Effects of boron, carbon, and iron content on the stacking fault formation during synthesis of ß-SiC particles in the system SiO2-C-H2, J. Am. Ceram. Soc. 81, 1255 (1998).

J.-H. Choi and G.-J. Lee: Stacking faults in silicon carbide whiskers, Ceram. Int. 26, 7 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JW., Lee, SS., Jung, YG. et al. Synthesis of SiC microtube with villus-like morphology and SiC fiber. Journal of Materials Research 20, 409–416 (2005). https://doi.org/10.1557/JMR.2005.0049

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0049