Abstract

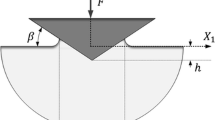

The use of an analytical approach to determine the relation between hardness and yield strength for materials with a high ratio of yield strength to Young’s modulus is re-examined. It is shown that predictions using the analogy of the spherical cavity fail to reproduce experimental and finite element results because the surface deflection that occurs during loading is not taken into account. A modification is proposed to allow this. This gives a greatly improved prediction of the relationship between the hardness and yield strength of a material. It also enables the effect of the indenter shape on the measured hardness to be incorporated and explains why in some very hard materials, indentation is observed to be completely elastic.

Similar content being viewed by others

References

A.G. Atkins and D. Tabor: Plastic indentation in metals with cones. J. Mech. Phys. Solids 13, 149 (1965).

Y.T. Cheng and C.M. Cheng: What is indentation hardness? Surf. Coat. Technol. 133, 417 (2000).

M. Dao, N. Chollacoop, K.J.V. Vliet, T.A. Venkatesh, and S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

M. Mata, M. Anglada, and J. Alcala: Contact deformation regimes around sharp indentations and the concept of the characteristic strain. J. Mater. Res. 17, 964 (2002).

M. Mata and J. Alcala: Mechanical property evaluation through sharp indentations in elastoplastic and fully plastic contact regimes. J. Mater. Res. 18, 1705 (2003).

D.M. Marsh: Plastic flow in glass. Proc. R. Soc. A 279, 420 (1963).

R. Hill: The Mathematical Theory of Plasticity (Clarendon Press, Oxford, U.K., 1950).

K.L. Johnson: The correlation of indentation experiments. J. Mech. Phys. Solids 18, 115 (1970).

W. Hirst and G.J.W. Howse: The indentation of materials by wedges. Proc. Roy. Soc. A 311, 429 (1969).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

I.N. Sneddon: Boussinesq’s problem for a rigid cone. Proc. Cambridge Phil. Soc. 44, 492 (1948).

I.N. Sneddon: Boussinesq’s problem for a flat-ended cylinder. Proc. Cambridge Phil. Soc. 42, 29 (1946).

S.S. Chiang, D.B. Marshall, and A.G. Evans: The response of solids to elastic/plastic indentation: I. Stresses and residual stresses. J. Appl. Phys. 53, 298 (1982).

A.C. Fischer-Cripps: Analysis of instrumented indentation test data for functionally graded materials. Surf. Coat. Technol. 168, 136 (2003).

T.O. Mulhearn: The deformation of metals by Vickers-type pyramidal indenters. J. Mech. Phys. Solids 7, 85 (1959).

L.E. Samuels and T.O. Mulhearn: An experimental investigation of the deformed zone associated with indentation hardness impressions. J. Mech. Phys. Solids 5, 125 (1957).

A.P. Singh and K.A. Padmanabhan: Axisymmetrical compression of solid cylinders. 1. Slow loading conditions. J. Mater. Sci. 26, 5481 (1991).

Y.T. Cheng and C.M. Cheng: Scaling approach to conical indentation in elastic-plastic solids with work hardening. J. Appl. Phys. 84, 1284 (1998).

Z-H. Xu and D. Rowcliffe: Method to determine the plastic properties of bulk materials by nanoindentation. Philos. Mag. A82, 1893 (2002).

L. Hultman, J. Neidhardt, N. Hellgren, H. Sjostrom, and J-E. Sundgren: Fullerene-like carbon nitride: A resilient coating material. MRS Bull. 28, 194 (2003).

Y.T. Cheng and Z. Li: Hardness obtained from conical indenters with various cone angles. J. Mater. Res. 15, 2830 (2000).

R. Hill, E.H. Lee, and S.J. Tupper: The theory of wedge indentation of ductile materials. Proc. R. Soc. A 188, 273 (1947).

F.J. Lockett: Indentation of a rigid/plastic material by a conical indenter. J. Mech. Phys. Solids 11, 345 (1963).

A.C. Fischer-Cripps: Elastic-plastic behaviour in materials loaded with a spherical indenter. J. Mater. Sci. 32, 727 (1997).

M. Mata, M. Anglada, and J. Alcala: A hardness equation for sharp indentation of elastic-power law strain-hardening materials. Philos. Mag. A82, 1831 (2002).

F. Giuliani, S.J. Lloyd, L.J. Vandeperre, and W.J. Clegg: Deformation of GaAs under Nanoindentation, in Electron Microscopy and Analysis 2003 (Institute of Physics, Oxford, U.K., 2003).

S.P. Timoshenko and J.N. Goodier: Theory of Elasticity. Engineering Societies Monographs (McGraw-Hill, New York, NY, 1984).

D. Tabor: The Physical meaning of indentation and scratch tests. Br. J. Appl. Phys. 7, 159 (1956).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vandeperre, L.J., Giuliani, F. & Clegg, W.J. Effect of elastic surface deformation on the relation between hardness and yield strength. Journal of Materials Research 19, 3704–3714 (2004). https://doi.org/10.1557/JMR.2004.0473

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0473