Abstract

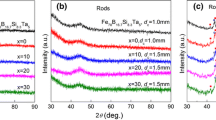

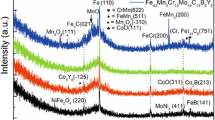

The glass formability of high-manganese amorphous steel alloysreported earlier by us has been found to improve upon additions of yttrium and lanthanide elements, enabling the formation of bulk glassy samples with diameter thicknessesreaching 7 mm by casting. Based on extensive studies using different Ln additions and systematic measurements of alloy oxygen contents, the intrinsic roles of Y/Ln in attauning good glass formability in both the high-Mn alloys and previouslyreported high-Cr alloys are revealed. The yield strengths of the non-ferromagnetic glassy alloys obtauned are estimated to be three times those of high-strength staunless steel alloys, and high elastic moduli in the range 150–200 GPa are measured. Furthermore, in the supercooled liquid regions, the glassy rods can be bent into various configurations by hand without fracturing. The observed plastic behavior together with the measured high mechanical strengths suggests that the present Fe–based bulk metallic glasses can potentially be developed as formable non-ferromagnetic amorphous steel alloys.

Similar content being viewed by others

References

V. Ponnambalam, S.J. Poon, G.J. Shiflet, V.M. Keppens, R. Taylor, and G. Petculescu: Synthesis of iron-based bulk metallic glasses as nonferromagnetic amorphous steel alloys. Appl. Phys. Lett. 83, 1131 (2003).

V. Ponnambalam, S.J. Poon, and G.J. Shiflet: Fe-based bulk metallic glasses with diameter thickness larger than one centimeter. J. Mater. Res. 19, 1320 (2004).

A. Inoue, B.L. Shen, A.R. Yavari, and A.L. Greer: Mechanical properties of Fe-based bulk glassy alloys in Fe–B–Si–Nb and Fe–Ga–P–C–B–Si systems. J. Mater. Res. 18, 1487 (2003).

T. Egami: Atomistic mechanism of bulk metallic glass formation. J. Non-Cryst. Solids 317, 30 (2003).

Z.P. Lu, C.T. Liu, and W.D. Porter: Role of yttrium in glass formation of Fe-based bulk metallic glasses. Appl. Phys. Lett. 83, 2581 (2003).

A. Migliori, J.L. Sarrao, W.M. Visscher, T.M. Bell, L. Ming, Z. Fisk, and R.G. Leisure: Resonant ultrasound spectroscopic techniques for measurement of the elastic moduli of solids. Physica B 183, 1 (1993).

Z.P. Lu and C.T. Liu: Glass formation criterion for various glassforming systems. Phys. Rev. Lett. 91, 115505 (2003).

P. Villars, A. Prince, and H. Okamoto: Handbook of Ternary Alloy Phase Diagrams (ASM International, Materials Park, OH, 1995).

M. Widom, D.M. Nicholson, and Y. Wang, private communication (2003).

Z.P. Lu, C.T. Liu, J.R. Thompson, and W.D. Porter: Structural amorphous steels. Phys. Rev. Lett. 92, 245503 (2004).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ponnambalam, V., Shiflet, G.J. & Joseph Poon, S. Fe−Mn−Cr−Mo−(Y,Ln)−C−B (Ln = Lanthanides) bulk metallic glasses as formable amorphous steel alloys. Journal of Materials Research 19, 3046–3052 (2004). https://doi.org/10.1557/JMR.2004.0374

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0374